- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision shafts

Results for

Precision shafts - Import export

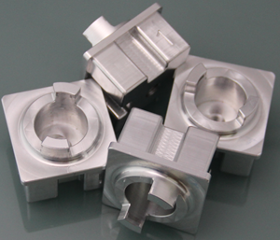

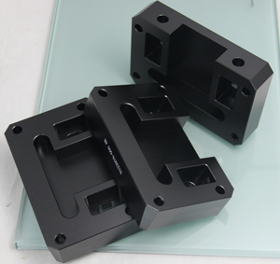

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

IGUS® GMBH

Germany

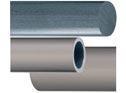

DryLin® R shafts and supported shafts - Technical data DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM Aluminum Low weight Lower wear of the plain bearing Corrosion resistant Ideal in combination with liners made of iglidur® J/J 200 Delivered off the shelf Steel Low-priced standard High load capacity Application in dry area Hard chrome-plated also available Lower coefficient of friction against plastic bearing Stainless steel High corrosion-resistance High resistance to chemicals Ideal solution for the wet area V4A for extreme chemical intensive applications Female thread, axial male thread Pins Groove cut-in Spanner flat Female thread, radial Special machining All shafts can be individually machined. Please send us your drawing. We'll submit an offer to you in a short time. Shaft request

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive-locking mechanical connection between the cus-tomer’s shaft and the sensor shaft ensures that the magnet in the sensor shaft precisely reflects the rotation of the cus-tomer’s shaft. With the TBN model, one rotation (i.e. max. 16,384 steps) is recorded.With the subsequent absolute transmission, the TRN shaft encoder reaches a measuring range of up to 4096 rotations. The position and speed values (PDO - Process Data Object) are output via the CANopen protocol.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A correct mechanical connection between the customer and sensor shaft ensures that the sensor precisely detects the customer shaft's rotations. A safe position is provided by the plausibility check of two sensor systems. Detected errors are evaluated. The CAN interface outputs the validated position value and speed signal via the CANopen Safety protocol within an SRDO (Safety Relevant Data Object) using 2x2 messages (normal and inverted). The rotary encoder meets the conditions of safety level SIL2 according to IEC 61508 and performance level "d" according to EN13849. The prerequisite of safety-relevant operation is a failsafe master.

Request for a quoteResults for

Precision shafts - Import exportNumber of results

15 ProductsCompany type