- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- position sensors

Results for

Position sensors - Import export

TWK-ELEKTRONIK GMBH

Germany

The linear transducer model PWA measures the absolute position of the plunger without contact or wear using an inductive resonator measuring system. This consists of an excitation coil which causes an oscillating resonance circuit (moving target) fastened to the plunger to oscillate. This in turn excites the receiver coils fixed in the housing, which are printed on a printed circuit board. The integrated electronics transform these signals (sin/cos) into a signal proportionate to the linear travel. The measuring system is insensitive to electrical and magnetic fields. 0(4) to 20 mA and 0 to 10 VDC are available as standard as analogue signal outputs. CANopen, IO link and SSI are in preparation. The sensor is fastened using at least two retaining clips HK-01 or using sliding blocks ST-01. The sensor can be equipped with ball joints at the front and rear. Alternatively, the sensor's plunger can be designed as a button.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Path measurement can be solved with various sensors. The inductive linear position sensors operate contactless and wear-free according to a revolutionary measuring principle. The position is not detected via a positioning magnet but via an oscillating RLC circuit. The product portfolio comprises magnetostrictive linear position sensors for position tracking in hydraulic cylinders or encoders for the tracking of floats as well as draw-wire sensors. Over a length of up to 40 meters, path information is transmitted in a highly precise and dynamic manner to the higher-level controller via digital and analog interfaces.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

The inductive linear position sensors of the Ri series operate contactless and wear-free according to a new, revolutionary measuring principle: The angular position is not detected via a positioning magnet but via an oscillating RLC circuit. The sensors are thus completely immune to magnetic fields such as generated by large motors for example. The measuring range of the rugged angle sensors is 360°. As starting variants analog voltage or current outputs and switching outputs are available.

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

Speed and Positioning Sensor with DGPS an Accelerometer Fusion

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1005 series are synchronized cylinders with spring return for use as actuating and control cylinders. The spring characteristic is freely selectable according to customer specifications. Also hub and piston rod protrusion are variable. The cylinder connection takes place via a head flange attachment and a threaded attachment on the piston rod. For flexible use there are connecting pieces for pipe fittings to BSPP ISO 1179-2 and venting connections on both sides. The cylinders are prepared for use with position sensor and position monitoring. With the exception of the piston rod and the centering surfaces, the entire cylinder is protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of the types H, HL and HLP according to DIN 51525-1. If you have any questions about areas of...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1004 series are synchronized cylinders for use as actuating and control cylinders. All cylinders work with low friction and run stick-slip-free. The connection is made via a head flange attachment and a threaded attachment on the piston rod. For flexible use, fittings for pipe fittings according to BSPP ISO 1179-2 and venting connections are available on both sides. Lift and piston rod protrusion are also variable selectable. Our cylinders are prepared for use with position sensor and position monitoring. With the exception of the piston rod and the centering surfaces, the entire cylinder is protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of the types H, HL and HLP according to DIN 51525-1. If you have any questions about areas of application or other options, we are...

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Angle position measurement by means of Hall sensors and signal processing including generation of the analogue output signal. Robust brass housing – stainless steel shaft with sliding bearing – sensor circuit consisting of ASIC with Hall elements – electrical connection via connector.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position by means of Hall sensor and signal processing, including generation of the analogue output signal. Incrémental ou absolu: Absolu

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position by means of a Hall sensor and signal processing including generation of the output signal - in addition to the angular position, a speed signal can also be output in digits / time unit - electrical connection via screw clamp (5-pin, conductor cross-section max. 0.5 mm²) or PTFE pigtail connector, 300 mm long - a CAN controller at the output enables connection to the CANopen network. According to CANopen Application Layer and Communication Profile, CiA Draft Standard 301, Version 4.1 and according to Device Profile for Encoders CiA Draft Standard Proposal 406, Version 3.0 and CANopen Layer setting Services and Protocol (LSS), CiA DSP 305. In the multiturn version, the number of revolutions is recorded in a counter. The position value is saved on shutting off the supply voltage. In voltage-free condition, the position value is recorded on movement of the shaft in a range of ≤ ± 90°.

Request for a quote

FRIWO GERÄTEBAU GMBH

Germany

•Supply voltage: 14V - 65V •Phase current: 300A •Motor types: PMSM •Control algorithm: Field oriented control with flux weakening •Functions: Automatic teach-in, four ride modes, reverse gear, boost, display control, smartphone app •Position feedback: Hall sensor •Analog inputs: 2 •Digital inputs: 2 •Communication: CAN, Smartphone Connectivity •Diagnostic interface: USB, CAN •Diameter: 155mm •Height: 45 mm •Weight: 970 g

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Speed sensors from Lenord+Bauer are particularly suited for continuous operation in durable capital goods thanks to the magnetic sensing principle. They detect rotational and linear motion. The sensors are protected against extreme weather conditions, humidity, shock, and vibration due to an encapsulation process and specially developed production methods. Thus they are in compliance with DIN EN 50155 and meet the requirements of protection class up to IP 68. Customised versions by adapting the housing, or different cable and plug fabrication, Lenord+Bauer can implement almost any installation position. Depending on requirement, the sensors generate single or multichannel squarewave signals alternatively as voltage or current signal ranging from 0 to 25 kHz. A standstill signal can also be implemented. On request ATEXprotected product variants, special output signals for functional testing, and sensors with integrated pulse division or pulse multiplication are available.

Request for a quote

IDENTPRO GMBH

Germany

The real time locating system by IdentPro uses 2D-LIDAR sensors for pinpoint positioning of lift trucks and other intralogistics vehicles. Localization takes place in the natural environment without artificial reference points as required by radio-based technologies. THERE locates indoors and out with a precision of ±10cm. Fast implementation without touching the warehouse infrastructure.

Request for a quote

IPF ELECTRONIC GMBH

Germany

For many tasks in the field of automation technology, it is necessary to recognize the motional processes in pneumatic and hydraulic cylinders and to detect the position of the piston with precision. For this, magnetic cylinder sensors are used.

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

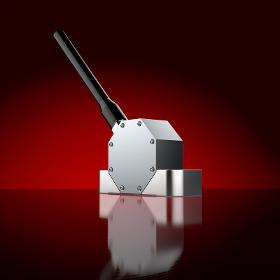

Maintenance and wearfree sensor for rotational speed and position measurement on gears, machines and motors as well for the use in hydraulic pumps or hydraulic motors. • Sensor with HTL/TTLoutput signals • Maintenance and wearfree operation due to contactless measurement of rotational movements • Appropriate for tooth wheels, slotted discs and sprockets

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

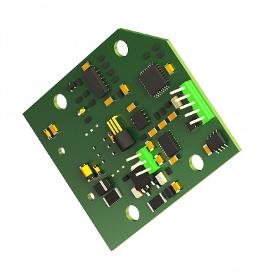

In rotary table applications, maximum precision counts when it comes to workpiece positioning. The exact mounting of the target wheel has a considerable influence on the achievable positioning accuracy, especially if the wheel has a small diameter. Thanks to the new i³SAACPrecisionSystem from Lenord+Bauer, this can now be significantly improved. The system also offers advantages for precise spindle speed control. • i3SAACPrecisionBox as part of the system for the minimisation of the eccentricity error • Increasing the system accuracy of incremental measuring systems • Ability to replace M23 connectors • Easy commissioning with the testing and programming unit GEL 211C • Function with standard MiniCODERs

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Encoders from Lenord+Bauer combine the benefits of a magnetic measuring system with a robust mechanical design. They have proven themselves in a wide variety of applications across the world, even in the harshest of industrial environments. It goes without saying that these encoders offer high reliability and a long service life. They provide exact measurement data even under changes in ambient temperature, fluctuations in humidity, strong vibrations, and condensation. This, however, requires some additional product characteristics such as protective coatings, encapsulation, or condensed water outlet. The incremental magnetic sensors work completely wear and maintenancefree and deliver analogue HTL, TTL or speed signals. The measurement resolution is up to 266,240 increments per turn.

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

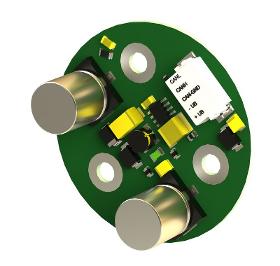

The compact, highresolution MiniCODERs from Lenord+Bauer have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wearfree and maintenancefree. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments. High measuring accuracy and compact design have made MiniCODERs the most frequently used speed sensors in highspeed spindles in the world. More than 500,000 pieces are installed, among other things, in machines for highspeed cutting. They are suitable for speed and position detection in all highly dynamic applications and offer now also digital motorfeedback.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Position sensors - Import exportNumber of results

17 ProductsCompany type