- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceuticals

Results for

Pharmaceuticals - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are made by aluminium, used for the mechanical support and connection, after process then doing sandblasting + natural oxidation.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

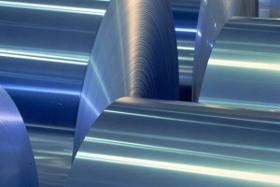

Novelis aluminum converter foil is a part of the light- or thin-gauge product group, ideally between 5 and 70 μm. They form flexible laminates with supporting materials like polymers or paper and additional lacquering and coating. Novelis is a preferred source of converter foil for global players in the flexible aluminum packaging industry, where it is then subjected to further processing, including laminating, extrusion, lacquering and printing, embossing and cutting. The versatility and flexibility of the products enable our customers to create a diverse range of packaging solutions, finding end applications across diverse industries such as food – including butter packaging and cheese packaging – pharmaceuticals, wraps, bottle capsules, laminated tubes, pouches and more.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

By providing not only a wide range of aluminum containers and aluminum lids but also packaging machines and technical support, OHLER Packaging Systems is able to offer a complete service to its customers. With more than 40 years of experience, OHLER plays a leading role as a food-industry partner for restaurants, caterers, kitchens, groceries and wholesalers, as well as airline food packaging.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Without aluminum, the entire supply chain could break down and become inefficient. Aluminum packaging is part of the solution and essential for sustainable growth. Light-gauge aluminum is unsurpassed as a reliable and versatile packaging material, and it is ideal for protecting food, pharmaceuticals and other products from light, oxygen, moisture and contamination. As a global leader in aluminum rolling and specializing in coil-coating, laminating, tray and container production, Novelis offers a range of products to satisfy practically any customer request. That’s why our aluminum packaging solutions are used for food containers, bottles and cartridges worldwide.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

OHLER offers a wide range of aluminum foil trays. All materials have been developed to be filled both manually and automatically. They are available in various sizes and thicknesses, and the trays can even be lacquered or printed. Our range of aluminum containers is complemented by a variety of accessories including aluminum lids, closing and sealing foils, coated carton lids, plastic snap-on lids, insulated transport boxes and closing machines. Our aluminum trays can be used both in microwave and conventional ovens or with barbeque grills. Aluminum food containers protect food from deterioration. The lightest “complete barrier” available, aluminum is impervious to light, gas, water vapor, oils, fats, oxygen and microorganisms. They keep foods fresh, safe and tasty, maintaining quality throughout a long shelf life.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

When it comes to creating the caps and closures our customers want, Novelis aluminum sheet and coil provide two distinct benefits – shape and appearance. Since aluminum packaging is strong but easily shaped, Novelis is able to produce innovative, customized shapes for caps and closures, as well as threading to make the aluminum containers resealable. These products can also be treated with a range of advanced decorative technologies including lithography, hot-foil and positive and negative embossing.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Aluminum cartridges protect the sealing compound with a diaphragm and seamed lid to prevent leakage, ensuring a long shelf life and preventing the contents from drying out. The two-component integrated system is suitable for fast-curing fillings and easily used with existing guns on the market while offering a variety of static mixer nozzles. Cartridges can be printed with customized art in up to six colors and have lacquer applied to the inside surfaces. Products include cartridges and a two-component integrated system.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The coaters series type LC were specifically developed for coating tablets. With our coater range, Loedige is one off the technological market leader. The maximised tablet bed surface in the Lödige coater and the maximum number of spray nozzles mean that extremely high liquid volumes can be applied with extremely high air supply volumes within a very short time. The newly designed, particularly low-turbulence air routing ensures a highly efficient and gentle use of dryer air. These features ensure a reliable coating process and short process times. Moreover, the low-turbulence air routing prevents contamination from the very start, thereby reducing the cleaning workload. Modern sensors permit optimisation of the spraying and drying process. Simple yet secure nozzle arm adjustment makes for easier handling.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige has years of expertise in continuous granulation. Nowadays, continuous ringlayer mixers are established systems for continuous granulation in many industries. However, until now the Lödige product range was missing a suitable dryer. The continuous fluid bed dryer closes this gap. Together with the ringlayer mixer CoriMix® and the customer-specific dosing system, this dryer provides a complete continuous granulation line: GRANUCON®. Dryer operation is based on the fluid bed process. A general disadvantage of continuous fluid beds is the wide retention time distribution within the machine. Lödige’s developers have looked into this problem and have found a solution: integrating a screw in the fluid bed dryer. This has a limiting effect on the retention time distribution. — Exchangeable floor — Quick screw removal — Integrated WIP cleaning — Individual purging of filter elements

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The granulation dryer is designed for continuous operation. A unique property of this dryer is its combination of convection and contact drying. Adaptation of the retention time to the specific process ensures that products are dried at low temperatures. At the same time, excellent granulation of the final product can be achieved. This intense mixing effect separates the particles in the fluid bed, thereby creating a large product surface and preventing the generation of temperature and moisture gradients in the product bed. This leads to a significant increase in the heat exchange via the heated drum walls. The product behaviour during drying is affected by the mixing tool geometry and choppers can be activated as an option; these can be used to control the average product retention time and the retention time distribution. It is therefore possible to achieve a defined grain size distribution during granulation processes

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The Lödige laboratory tablet coater has a modular design, so that integration of any components is customised according to the customer’s specific requirements. A dividable drum and a dividable nozzle arm allow processing of even very small volumes (0.6 l). The coater and the optionally available liquid supply station consist of Corian®, a highly resistant, light-weight, FDA-approved material, which is crucial for the particularly functional and modern design of the laboratory coater system. The laboratory coater is not just a “laboratory machine”, but a full coating system, in which process conditions comparable to those of Lödige production coaters are generated. The mobile laboratory coater incl. the drum for the tablets and drawer for the nozzle arm and tool form the base unit. In addition, the following equally mobile modules are available: — Air supply unit — Exhaust air unit — Liquid supply station (optional)

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory vacuum shovel dryer DRUVATHERM® is a system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production too. The Lödige laboratory vacuum shovel dryer DRUVATHERM® is a horizontal, batch vacuum dryer with a frequency-controlled mixing tool. This mixer consisting of mixing elements adapted to the process and arranged on a shaft according to a specific system - is installed in a cylindrical mixing drum equipped with a temperature control jacket. Rotation of the mixing unit generates a three-dimensional product movement, in which all of the product is constantly in motion. The contact frequency of particles with the heat exchange surface leads to shorter drying times. The chopper rotating at high speeds fitted to the side of the mixing drum is used to disperse the product . This leads to a significant increase in drying capacity and prevents moisture and temperature gradients.

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Coatings made of PFA and PVDF fluorine-based thermoplastics provide safe protection against corrosion even on exposure to aggressive media. Because its molecular structure resembles that of PTFE, PFA is almost universally resistant to chemicals. Other special features of PFA linings are their wide range of operating temperatures and easy cleaning due to the material’s non-adhesive nature. In many applications, this makes it possible to replace stainless steel with a raw material which is not only much more economical but also easier to process. Because coatings are applied in a thermoplastic transfer-moulding process, it is necessary to account for certain design aspects which our team will gladly discuss with you in advance.

Request for a quoteResults for

Pharmaceuticals - Import exportNumber of results

15 ProductsCompany type