- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oxidation - metals

Results for

Oxidation - metals - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

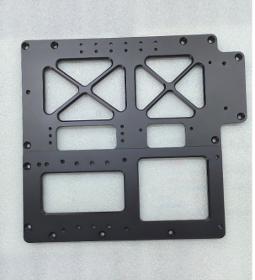

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The benefits of using aluminium in machine and plant construction are abundant: although aluminium is considered to be a light metal with a density of 2.6 to 2.8 g per cm³, which offers potential weight savings of up to 66% compared to steel and stainless steel, it still has exceptional strength considering these properties. However, the design and concept of steel constructions can often not be transferred one-to-one, due to the higher malleability and lower residual stress of aluminium components. An additional benefit is the aluminium's inherent resistance to corrosion: When exposed to oxygen, the light metal forms an oxide coating, which is immediately regenerated upon permeation. Standard processing methods, such as MIG, TIG and CMT welding can easily be used on aluminium without hesitation – particularly on substrates that are also made of aluminium. In some instances, they can be carried out more easily, more quickly and using simpler equipment, which results in further...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Oxidation - metals - Import exportNumber of results

3 ProductsCompany type