- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- non-ferrous metals

Results for

Non-ferrous metals - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

On request, we can supply aluminium alloys in the form of rod or bar. These are available in most of the commercially available aluminium alloys. The tolerances of extruded aluminium rods and bars can also be further improved by subsequent drawing. In recent years, ALUnna has specialised in the production of rod and bar meeting the highest quality standards. If you require a specific delivery option for rod or bar such as special testing then we will definitely find a solution for you.

Request for a quote

ANTHERMO GMBH

Germany

Buttweld fittings according to ANSI B 16.9 Extensive stock range in special materials We can deliver Buttweld Fittings in numerous dimensions and materials directly from stock at short notice. Pipe bends with different radii (seamless and welded), T-pieces, reducers and caps essentially make up the product groups Buttweld Fittings (buttweld fittings). We only deliver goods of European origin. Special materials In particular, we supply special materials, which are generally only rarely requested, at short notice from our extensive range in stock. The following special materials are available at short notice: Low Temp Steel A 420 WPL6 / WPHY52 Chrome-Moly A234 Alloy WP5 Chrome-Moly A234 Alloy WP11 Chrome-Moly A234 Alloy WP22

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Powerful and fast forming. The type UMR tube forming machine uses smart operating technology with many preset settings that can be retrieved automatically to achieve perfect mirrorlike surfaces. When producing flaring with 20°90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

All the options in one single machine forming, cutting, postbending cutting, threading. Our rotational technology increase the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servoelectric by design and, if needed, CNCoperated. In our SRM typeforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or postbending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

ANTHERMO GMBH

Germany

(Socked-Weld-Fittings) Straight from our warehouse We always have numerous versions of weld-in fittings (ANSI B 16.11) available in our extensive warehouse in Kamen. We can also supply you at short notice. We only deliver goods of European origin. 3 types of reducing inserts Insert reducers are available in three different types (see technical data sheet in the download area). Standards and special requests We supply weld-in fittings as standard in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply 9000 lbs and special materials if required. Technical specifications You can find more details, technical data and dimensions in our data sheet "Weld-in fittings" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

ENGRAVING TOOLS For engraving plastics and non-ferrous metals. The width must be ground by you, to suit your requirements.Engraving cutter and engraving stylus: For engraving plastics and non-ferrous metals. The ""typeface width"" must be sanded down in-house. Engraving cutter 60 °, point angle 60 °, number of teeth 1, spiral angle 30 ° r."

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

As a competent industrial partner, we produce stamped, bent-wire and formed components from stainless steel, non-ferrous metals and regular steel in a consistent quality. Dependability and flexibility characterize our performance. Our experience and technical know-how enable fast response and economical pricing. Benefit from the experience our staff have gathered with these products. We can competently process small as well as large orders. Possible material thicknesses: 0.5 to 4.5 mm. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

GSW SCHWABE AG

Germany

Cut-To-Length Lines are core competence at GSW. They belong to the family of Cutting Lines and are designed to process diverse materials out of steel, non-ferrous metals or aluminum and precisely cut a coil into sections of equal length (which is where the name comes from). Starting with narrow slit strip and finishing somewhere beyond 2000mm width – our Cut-To-Length Lines always know how to shine in this process.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

DURSOL-FABRIK OTTO DURST GMBH & CO. KG

Germany

AUTOSOL®MARINE STAINLESS STEEL POWER CLEANER Ideal for stainlesssteel surfaces, anodised and enamelled metal surfaces, light and non-ferrous metals on boats. Powerfully removes dirt as well as greasy and oily residues.

Request for a quote

DURSOL-FABRIK OTTO DURST GMBH & CO. KG

Germany

AUTOSOL® METAL LIQUID GUARD Provides long-lasting protection for all metal surfaces made of stainless steel, copper, brass, chrome, aluminum, etc. The product forms a water-repellent protective layer and leaves the surface looking clean and shiny. Prevents tarnishing of non-ferrous metals and minimizes the adhesion of dirt, dust, water stains and fingerprints.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

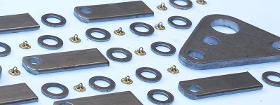

Custom-designed clamping systems for pipes, tubes, hoses, cables and other components according to customer`s specifications or based on STAUFF developments, made of thermoplastics, metals and non-ferrous metals. Accessories such as weld plates, cover plates, bolts as well as rubber inserts are available on request.

Request for a quote

KAMAT GMBH & CO. KG

Germany

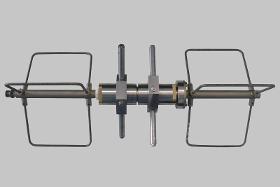

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Optimum surface cleaning with KAMAT high-pressure rotating nozzles In order to ensure a surface treatment with excellent results and within a reasonable time, we have developed special externally driven rotating nozzles suitable for our high pressure pumps: Depending on the customer's requirements, our nozzles can be driven pneumatically, electrically or hydraulically. With traditional, self-powered rotating nozzles, the water jet hits an angle before it exits the nozzle, causing the nozzle to rotate. Driving the rotating nozzle causes the water jet to lose energy and is therefore much less efficient. Our externally driven rotary nozzles concentrate the hydraulic energy entirely on the machining process. KAMAT rotating nozzles provide coherent jets that can be moved precisely and quickly over large areas. In the case of externally driven rotation, the hydraulic energy is used entirely on the surface being sprayed, giving excellent and efficient results on surfaces.

Request for a quoteResults for

Non-ferrous metals - Import exportNumber of results

220 ProductsCompany type

Category

- Pipe and tube fittings - ferrous metal (158)

- Pipes and tubes - ferrous metal (16)

- Wires and cables - ferrous metal (14)

- Hand tools, non-power (8)

- Pipe and tube fittings - non-ferrous metal (5)

- Pipes, bent - ferrous metal (3)

- Nozzles - ferrous metal (2)

- Sections - non-ferrous metal (2)

- Ceramics, refractory (2)

- Cleaning products for information technology (2)

- Gas fittings (2)

- Bars - non-ferrous metal (1)

- Rolling mills - ferrous metals (1)

- Sections and bars - non-ferrous metal (1)

- Metal straightening machines (1)

- Offshore construction (1)