- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- needle roller bearings

Results for

Needle roller bearings - Import export

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

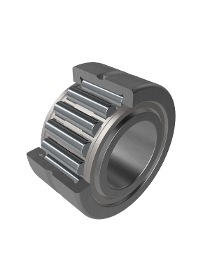

KIS needle roller bearings are ideal for applications that require space-saving rolling bearings with high load carrying capacity. We offer needle roller bearings in both radial and axial designs as well as in combined designs. In bearing technology, cylindrical rolling elements are referred to as needles if the rolling element diameter is ≦ 6 mm and the ratio of rolling element diameter to rolling element length gives a value Dw/lw < 1:3. Radial needle roller bearings are intended exclusively for use as non-locating bearings. The given axial displacement path for bearings with an inner ring allows axial movements between the shaft and the housing. If necessary, wider inner rings are available to allow larger axial displacement paths. Our combined needle bearings are characterised by particularly high precision and efficiency. By integrating both bearings into one unit, combined needle roller bearings are often easier to press in and easier to handle than individual solutions.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Customised system or individual part solutions are our core competence at KIS. We develop complete solutions for you based on our own KIS products and combine them with our comprehensive service for drive technology. Whether it's a careful selection of individual components or proper assembly ensuring your application functions perfectly: As bearing specialists based in Germany, we’re there for every step of the process, from development and construction, through monitoring of production and assembly, to quality inspections and practical tests.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

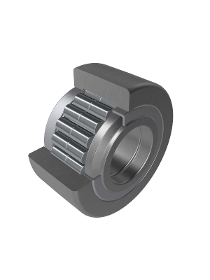

Similar in design to yoke type track rollers with axial guidance, our KIS cam rollers are based on needle roller or cylindrical roller bearings. Instead of an inner ring, they are equipped with a solid bolt. This serves as an inner ring replacement and is provided with a fastening thread. They are ideal for applications that require high rigidity, load carrying capacity and guiding accuracy. Our stud type track rollers are used, for example, in conveyor technology, machine tools and medical technology. Depending on the application requirements, the KIS range offers a wide variety of designs. We are happy to advise you on the right solution for your application!

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our yoke type track rollers are available as single or double row needle roller or cylindrical roller bearings. Depending on the application requirements, the KIS range offers different ready-to-fit variants. Equipped with particularly thick-walled outer rings, our yoke type track rollers can support high radial loads and tolerate axial loads from minor misalignments, skewed running or short-term start-up shocks. Yoke type track rollers are mounted on axles and supported on a flat raceway (mating track). To meet specific requirements, we offer a wide range of different variants. Together with you, we develop the customised KIS solution carefully considering the use of cages, rib rings, seals and the profile of the outer ring running surface.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

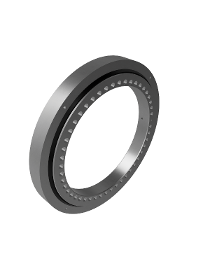

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

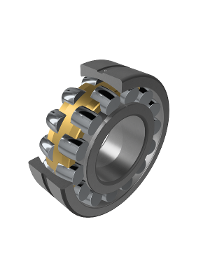

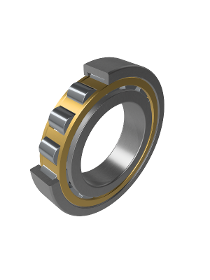

We offer our KIS cylindrical roller bearings in various designs and sizes. In addition to the number of roller rows and the design of the cage, the flanges on the inner and outer rings are also considered. Due to their low friction and high rigidity, our cylindrical roller bearings are the perfect, durable solution for applications with high radial loads. They can also compensate for axial displacements (e.g. due to thermal expansion) and are available in sealed designs. Sealed cylindrical roller bearings are protected from dirt, water and dust. The seal prevents the ingress of contaminants and keeps the lubricant in the bearing. Together with you, we will be happy to develop a customised KIS solution for your requirements.

Request for a quoteResults for

Needle roller bearings - Import exportNumber of results

8 ProductsCompany type