- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moulds for heat exchangers

Results for

Moulds for heat exchangers - Import export

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

ANTHERMO GMBH

Germany

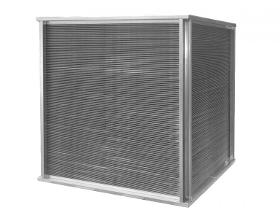

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Know-how for special applications There are applications with very special requirements for the heat exchanger. Due to its decades of experience, Anthermo GmbH has the necessary know-how to be able to build special heat exchangers for special applications. So every year we build numerous heat exchangers that are a bit off the standard. Dimensioning with EDP programs With the help of EDP programs, Anthermo GmbH is also able to dimension and technically design special heat exchangers. The technical design and dimensioning is strictly based on the specifications and requirements of the customer. After the design, a three-dimensional CAD model is created. The CAD drawing approved by the customer forms the basis for production with the most modern IT-supported production systems.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

KELVION HOLDING GMBH

Germany

This new addition to our product line is a compact heat exchanger made from high-alloyed stainless steel and can handle temperatures up to 550°C. Its compact and modular design makes it extremely versatile and easy to service. Our exhaust gas heat exchanger is designed to recover heat from exhaust gas produced for example by combustion engines used in combined heat and power plants. The heat exchanger transfers the heat from the exhaust gas to a liquid (water or water-glycol solutions). When heated up, this liquid can be used in central heating systems; for preheating air in the combustion chambers of furnaces and turbines; to dry coal, pulp, wood and other materials as well as for generating electricity with a Rankine process.

Request for a quote

KELVION HOLDING GMBH

Germany

If a commercial product does not meet the market demands, our Customized Air Cooler product line offers a design-to order process, with your application needs as the starting point. We optimize the total quotation process and tailor our manufacturing to fulfil your requirements. We start with the widest possible product portfolio, offered in our selection software. Our Sales teams can provide non-standard, design-to-order, industrial or OEM solutions. It is a critical feature of our quotation and manufacturing process that we check the design at the earliest opportunity to avoid risk.

Request for a quote

KELVION HOLDING GMBH

Germany

The wide range of product portfolio of coils with different tube diameters, tube patterns, fin profiles, materials and options allows us to customize our coils for any specific application and fluids: air heaters, air coolers, condensers and evaporators for HVAC and various industrial applications. Kelvion heat exchanger coils are manufactured with copper tubes and aluminum or copper fins. The fins are equipped with special profiles developed at our R&D department enhancing heat transfer and keeping pressure drop at a moderate level. The customized fin spacing is achieved by collars which also provide the contact between the fin block and the tubes. Mechanical expansion of the tubes guarantees a perfect bond between the fins and the tubes leading to maximum heat transfer between both fluids.

Request for a quote

KELVION HOLDING GMBH

Germany

The Kelvion range of Commercial Air Coolers is designed for most refrigeration applications. In addition to predefined variants, there is the flexibility to include options and accessories to meet our customers’ demands. Their capacity and size are optimized to facilitate the stocking and competitive transportation of products directly, or via our distribution and wholesale channels. Commercial products are defined within the sales brochures, selection software and product configurator – all with specific price lists.

Request for a quote

KELVION HOLDING GMBH

Germany

Different applications require different designs for an optimal fit, so we provide Shell & Tube heat exchangers in single tube design with plain, low and high fin tubes and also with compact fin bundles. The plain tube design is most suitable if media have similar heat transfer properties, where the compact fin design means the best possible performance if there is a substantial difference in heat transfer rate, for example when exchanging heat between oil and water. The low and high fin single tube solution is between the previous two designs in order to further optimize on flow, pressure drop and velocities of media.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGE GROUP

Germany

Breech‐Lock Closure Heat Exchanger

Request for a quoteResults for

Moulds for heat exchangers - Import exportNumber of results

20 ProductsCompany type