- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- marking machines

Results for

Marking machines - Import export

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine technology developed for coating round steel tubes with a temporary corrosion protection convinces with its high performance. The surface quality of the solvent free coating with 100 % UV lacquer, the fast curing time of ≤ 1 second as well as an overspray recovery rate of more than 95 % are impressive features which, by their very nature, offer high economic efficiency. Additional modules individually perform either the cleaning work, dust removal or marking of tubes. This machine technology ensures perfect transport of the tubes without damage to the lacquer coat, while flexibly taking tube properties into account, such as sleeves or caps, diameters from 20-200 or from 200 to 500 mm, required throughfeed speeds of 30 - 100 m/min as well as surface temperatures from +1°C to +40°C. Whether operated as an individual machine or integrated in an adjustment line, the output parameters are characterised by minimum space requirement and low operating and maintenance costs. An alkaline cleaning station that adjusts to the individual degree of soiling of the tube surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line. Venjakob offers individual system solutions for coating tube sleeves. This includes the application of a base coat and coloured rings, as well as marking. Customised solutions for tube marking are available as an option.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

Handjet EBS-260 stands for unrestricted mobility, easy handling and operational capability even under rough operating conditions. The coder has many useful functions for everyday operation that make your life easier. High efficiency through low ink consumption and long battery life help you to reduce your operating costs significantly. No more wasting time transporting your products to the printer. Bring the printer to the product! The Handjet EBS-260 is easy to transport and does not require much preparation. The coder weighs only about eight apples. Tired arms are a thing of the past. You can easily work for hours and don't even feel the weight. Objects that are difficult to access, such as ventilation pipes, are often only accessible overhead. Thanks valve technology, the handjet prints in any position. Learn more on our homepage and convince yourself!

Request for a quote

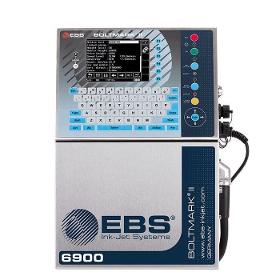

EBS INK JET SYSTEME GMBH

Germany

EBS-6800P is an industrial one head INK-JET printed engineered for tagging pieces that move on a factory conveyor with no direct communication. System for tagging immobile pieces can also be accessed which are based on mobile print-head technique wherein the print heads can be regulated mechanically or physically. The pigment inks used in our printers allow print on a variety of dark substrates. Other inks allow high contrast and good coverage prints of any surfaces, also work well on multi-colored substrates. With our know-how you will find the right Ink for every application. The EBS BOLTMARK II series is fitted with an integrated ink system, which can be changed in 3 simple steps in less than a minute. No technician and no tools needed. Equally, the quick change of ink and solvent bottles works in the same way. Protection class IP44 and IP54: Protection of the housing against intrusion of water and coarse dust guarantees high reliability of the printer over a long period.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

In the ink jet segment the EBS 1500 is known for it's simple but efficient handling. The printer can get equipped with a bunch of different printheads, optional from 16 nozzles up to 128 nozzles. Expressed in font height this means from 6 mm up to 230 mm. With our EBS-1500 you can operate up to 6 printheads with one controller. This is a big advantage for companies with several parallel production lines. It is possible to print a different project with each head. It's even able to work with pigmented inks. This brings you the maximum contrast for difficult materials. The EBS 1500 combines word processing with graphics, barcodes and data matrix codes in an easy-to-use graphical user interface. With features such as IP54 protection and the ability to connect up to 6 print heads to one controller, this coder is the right tool for large production lines and harsh conditions.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

The new generation of BOLTMARK ® II printers has increased in terms of performance, functionality and reliability. Our engineers have created a product that will not let you down, even under the toughest conditions, and will also work highly efficiently. ACPS - Anti Clogging Power Supply: Worldwide innovation: for the first time in a Continuous Ink Jet Printer, a built-in automatic and intelligent system provides reliable printer operation in case of power failure. Should the power be interrupted for less than 30 seconds, the printer continues operating. If the supply is cut off for more than 30 seconds, the printer starts the automatic shutdown procedure including rinsing, to protect the tubes from dried ink deposits. As soon as the power is restored the printer is quickly operational again. The ACPS contains very long-lasting Super Charger Capacitors, not conventional accumulators. Charging lasts only around 2 minutes. The ACPS is available optionally only for EBS-6600 and EBS-6900.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EBS INK JET SYSTEME GMBH

Germany

EBS-7200 is a fast, single-head industrial printer of the type "INK-JET" (ink drop ejection) which can be used for non-contact marking of objects that move for example on a belt conveyor. The marking speed of this printer is exceptional. It is 46% faster than the 6500 and 6800 and is therefore designed for marking tasks that require an exceptionally high marking speed. The device is designed for printing with different coloured dye inks (i.e. homogeneous, pigment-free inks). The commercial versions of the printers differ in the maximum height of the printed image (MVP - maximum height of the vertical row of dots), which can be 16 (25 or 32 as an option) dots.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

Our EBS-6600 is the first model from the brand new Boltmark II-series. It's an industrial single-head Ink-Jet printer designed for coding moving objects on a factory conveyor without requiring direct contact. It's able to code from 1.2mm up to a maximum of 14mm height with a max. amount of up to 25 dots [depending on text profile].

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

The ink-jet printer EBS-230 of the "PicAS"-series sets new standards in regard to configuration and cost-effectiveness of basic DOD (Drop on Demand) systems, which remain relevant to newest DOD systems. With a print height of 6mm up to 27mm (depends on selected version) and a print speed up to 60m/min the EBS-230 is the perfect marking system for small to medium production volumes. The ability to use fast-drying inks on Ethanol-, Acetone- or MEK base provides a universal solution for various marking applications. No matter if the surface is made of cardboard, plastics, metal, glass or ceramics. Trough a process of consistent development of the established line coder "PicAS" EBS-200 we created a totally splash water protected system which is also independent from external compressed air.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

3 sizes for marking of flat glass panes and Hollow glass bodies with logo's or lettering, max. 25,38 and 54 mm diameter! The device consists of in detail 1 tank made of sturdy steel plate, 6 liters. Contents, 3 feet, mounting bracket, lockable Fill cap for the blasting agent (corundum), and overpressure nozzle with filter element Needle felt (easy to replace). 1 special blasting gun with built-in injector nozzle, and venturi wide mouth – blasting nozzle and Compressed air connection nipples. 1 special distribution head for receiving the stencil, which are rapidly renewable, and the Recycling of the blasting agent in the container or in the filter element. 1 set = 4 pcs. Connecting hoses between blasting gun and containers or distribution head and the container.

Request for a quoteResults for

Marking machines - Import exportNumber of results

10 ProductsCompany type