- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- maintenance products

Results for

Maintenance products - Import export

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aeronautical industry, lift platforms serve as transport means, e.g. for complete fuselages, or also as an assembly aid during component production. With telescoping maintenance cage.

Request for a quote

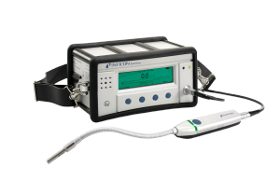

INFICON GMBH

Germany

The portable Extrima Leak Detector is the ultimate intrinsically safe instrument for leak detection in the toughest environments, including hazardous locations such as Zone 0 (corresponding to Division 1). The Extrima allows you to quickly find leaks on a wide range of industrial applications such as aircraft and hydrogen cooled generators. With the Extrima the aviation industry has a safe, accurate and yet simple solution for leak testing of complete fuel systems, both in production and maintenance situations. Thanks to its high sensitivity, the Extrima can detect even minute leaks with pinpoint accuracy. Extensive tests have shown that using the Extrima can reduce the average time by more than 50 % for identifying, locating and repairing a leak on a fighter jet during maintenance. Click here to see how easy it is to find leaks on aircraft fuel system using the Extrima (video 3:55, YouTube). It is certified for use in Zone 0, classification Ex ia, IIC T3 with ATEX, IECEx,...

Request for a quote

INFICON GMBH

Germany

The Sensistor ISH2000 is a robust instrument for professional leak detection, both manual and automatic. The unique method involving the use of inexpensive forming gas (5 % hydrogen and 95 %nitrogen) as tracer gas. This combines unmatched measuring properties with user-friendly technology, low costs and minimal service requirements. This makes the Sensistor ISH2000 the best option for a wide range of production and maintenance applications. It is especially suitable for finding leaks of a size that would leak liquids such as water, fuel and oils or in environments with occasional large leaks. Sensistor ISH2000 Hydrogen Leak Detector is available as desktop and panel versions.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow ultrasonic - as a replacement for the current and widely used standard measuring variant with impeller, turbine or vortex - now makes contactless measurement according to the ultrasonic principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. Alternatively, the mechanical flow measurement according to the differential pressure principle is available with the proflow mechanical. Easy to integrate in machines and plant lines 4 or 6 x consumer channels (forward/return) 1/2“ With LED-display on fl ow sensor Temperature measurement PT 1.000 Big RED/GREEN Status LED 1 x main connection 1“ Flow rate each channel 1 ... 30 l/min (no „overload-risk“-> 60 l/min possible]) Operating temperature: 0 ...120 °C

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND NEARLY MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow mechanical - as a replacement for the current and widely used standard measuring variant with impeller or turbine - now makes mechanical measurement according to the differential pressure principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. A completely non-contact flow measurement based on the ultrasonic principle is available with the proflow ultrasonic. Robust flow measurement in consumer return line PT 1.000 temperature measurement in consumer return line 6 x 2 consumer channels 3/4“ female screw thread 1 x 2 main connection 1“ female screw thread Available in three temperature variants: operating temperature up to 100°C, up to 160°C and up to 180°C Max. flow rate each channel:: 25 l/min or 50 l/min

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CBG COMPOSITES GMBH

Germany

Our care products specially developed for Plexiglas help you to maintain the beauty and value of the material for years and decades. In comparison to silicate glass, two properties must be taken into particular consideration when caring for and cleaning acrylic glass. On the one hand the lower surface hardness and therefore higher susceptibility to scratches of acrylic glass, on the other hand the susceptibility of acrylic glass to solvents, especially organic ones. The use of incompatible polishing materials can cause stress cracks and matt surfaces. With fakopol® a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics. It has both cleaning and polishing action, removes wipe scratches and marks and is ideal for finishing of industrially manufactured parts. Gives long-lasting protection and glossy deep shine. The treatment process is quite simple.

Request for a quote

CBG COMPOSITES GMBH

Germany

fako® cleaning and polishing milk no. 9322 is a maintenance agent at your disposal that especially meets the demands of Plexiglass and other acrylic glasses, plastics as well as gel coat finish and fiberglass. It is used for regular care, removal of marks, dirt and minor scratches, oxidation, yellowing and chalking, gives plastics optimum protection with dust-repellent properties and preserves their natural brilliance. Matt panes become radiantly clear again. Maintenance is simple and straight forward with excellent results. The use of fako® Polishing milk does not lead to stress-corrosion cracking.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quoteResults for

Maintenance products - Import exportNumber of results

11 ProductsCompany type