- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machines

Results for

Industrial machines - Import export

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

GSW SCHWABE AG

Germany

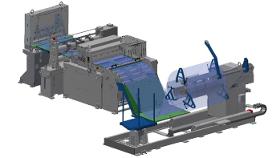

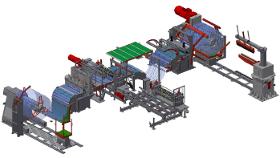

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

- made of steel - with safety housing - desktop machine or stand-alone - incl. CNC control Zero3 - incl. ConstruCAM-3D software - incl. Estlcam software - 16 different sizes available

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

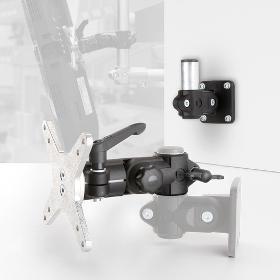

RK monitor mounting – high-strength, flexible and individually adaptable VESA or universal mount for connecting monitors, displays or control panels. Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too. Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

VESA or universal mount for connecting monitors, displays or control panels Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics encapsulation The FLEXline series offers maximum flexibility through the modular design of various variants as well as expanded options for implementing special functions. The adaptation or addition of individual mechanical components is just as possible as special programming or integration into a complete production line. In addition, various application systems are available, including hot runner systems with different nozzle geometries and arrangements. The melting units can be optimally tailored to the requirements of the respective project with different melting and conveying systems and, if project requirements differ or change, can be replaced at any time using our "plug-and-play" system. Extensive peripherals and additional options round off the system. The FLEXline can therefore be optimally tailored to the requirements of the respective project.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics casting The BASEline series combines a compact design and convenient operation and can be used optimally for the majority of low pressure molding projects. Various mechanical components can be put together depending on requirements. The adapted melting device with double-acting piston pump, 4l tank volume and a melting capacity of approx. 1kg/h enables optimal processing of small to medium shot weights and/or quantities. The available clamping force of 9/12kN is suitable for casting surfaces up to approx. 3,000mm². By using the Siemens S7-1200 control with touch panel, the series offers the same ease of use as the larger series.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

AIR- AND WATER COOLED COLD WATER UNITS gwk chillers in the sklc series are air-cooled compact cold water units with integrated condenser gwk chillers in the skw series are water-cooled compact cold water units cooled with external cooling water These chillers are equipped with screw condensers; the power regulation of the capacity to be dissipated is continuous. Water-cooled cold water units in the skw series with low coolant content can be operated very efficiently and are preferably used when the available cooling water from gwk cooling towers, gwk free cooler systems or customer-provided supplies has a higher temperature level than required for the production process but is available inexpensively..

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Whenever the process requires high temperatures and the advantages of water as heat carrier (best heat conductivity properties, inexpensive, low viscosity) are to be used, this construction series is the best solution. Absolute reliability, high regulating accuracy, easy operation and a favorable price /performance ratio: apart from the versatile performance features a modern temperature controller has to fulfill, these are the key criteria for the temperature controllers teco wh/whx. As one-circuit and multi-circuit units, our modular temperature controllers in the teco whx series cover a wide performance spectrum. Heating capacities of 12 to 600 kW, max. possible cooling capacities up to 1460 kW* and pump flow rates of max. 200 m3/h are impressive basic data of these technically sophisticated temperature controllers for operation with compressed water up to 220 °C.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMPTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. In the selection series we used the most frequently selected equipment features and heating performance of the proven premium series advanced. The protemp selection temperature control unit is particularly suitable for the supply of multi-circuit water distributors and is designed for the display of up to 6 external proflow temperature control channels.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

With the decentralised solution, gwk adds a machine series that offers a high level of flexibility for numerous applications to its portfolio. The customer can individually and precisely set the ideal cooling water temperature for every production machine and for every process in production. Thanks to the direct connection to the consumer, there are no thermal losses, but instead a high flow rate and constant pressure. The weco wd series consists of easy to operate plug&play machines that can easily be installed and commissioned. Three processes can be run with the solution: Free cooling, refrigeration process for low temperatures down to -5°C and temperature control up to 90 °C –everything can be chosen as desired. There is a total of four models with cooling powers between 14 kW and 36 kW (at 15 °C feed flow temperature) and heating powers between 9 kW and 36 kW.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The integrat 80 is used for the modular temperature control with water up to 140°C in the basic version with up to six temperature control circuits to be operated completely independently of each other. The basic version can be expanded with extension columns and up to 24 temperature control modules. As an option, the temperature control circuits can be extended with the 4-way distributor vtc with flow and temperature measurement. Thus, a maximum of 96 temperature control circuits can be monitored with the vtc 4-way distribution system. In conjunction with the standard heating control system used as standard, a homogeneous temperature profile on the mould cavity surface is achieved in an extremely energy-efficient manner, as well as with constant cooling by using a motor valve. As an option, the pumps can also be operated with frequency control unit. This improves the procedural results and contributes to energy savings.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Dynamic mould temperature control is a temperature control method that allows temperature variations within the cycle and is also known as “variotherm temperature control”. While this method has been known for almost forty years, it has only undergone a dynamic development in the last few years. This is due to the increasingly exacting quality requirements of consumers (e.g. prevention of visible joint-lines, gloss variations and other surface defects) and the use of plastic materials in new applications. When a temperature control system is selected it is important to mind that it matches exactly with the application and that the economic benefit justifies the technical efforts as well as the energy consumption.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

MULTI-ZONE TEMPERATURE CONTROL- AND MONITORING SYSTEM WITH NON-CONTACT FLOW MEASUREMENT. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using the frequency inverter, the already high basic efficiency is optimized and the pump characteristic curve will be optimally adapted to the respective operating conditions. The flow measurement of the individual temperature zones is carried out using noncontact measurement technology according to the ultrasonic principle.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The patented gwk solution includes cold water temperature controllers that can be operated without glycol in the temperature range between 0 °C and 25 °C. The user can select between two models that are differing in cooling capacity and flow rate. A precise microprocessor control with simultaneous indication of nominal and actual value, the simple one-touch operation, optional interfaces at the front panel and external sensor connection, splash-water proofed electrics and the cabling with CEE-socket ready for connection make the unit ready for immediate use. Leak stop operation, mould draining, acoustic alarm, automatic filling and top up, additional manual filling possibility for conditioned water, strainer in the cooling water connection and parts out of corrosion resistant materials that are in contact with the medium are part of the comprehensive standard equipment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNOTRANS SOLUTIONS GMBH

Germany

Brand-new perspectives and possibilities are offered by the dynamic temperature control with CO2. This new and environmentfriendly procedure really provides a solution for heating and cooling of complex and thinwalled moulded parts. By using gaseous media for heating and cooling processes, soiled cooling channels are now a thing of the past. Basically it is true that gaseous media have the disadvantage to be bad heat carriers. This applies at least to air that is only used for cooling processes under special circumstances. But in contrast, if the opportunities of CO2 are exhausted properly, it offers an interesting alternative to conventional water temperature control.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using an optional frequency inverter, the already high basic effi ciency can be more optimized and the pump characteristic curve can be optimally adapted to the respective operating conditions. PROTEMP SERIES 1-4 ADVANCED Water temperature control unit up to 95°C -140 °C Cooling capacity: 105 - 717 kW Heating capacity 9 - 50 kW Digitization concept „protemp connect 4.0“ Dual frequency version (50/ 60 Hz), motor IE3 class Energy consumption display Pump speed control OPC UA interface

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Absolute reliability, high regulating accuracy, easy operation and a favorable price/performance ratio: apart from the versatile performance features a modern temperature controller has to fulfill, these are the key criteria in the teco wi temperature controller series teco wi. As one-circuit and multi-circuit units, our modular temperature controllers in the teco wi series cover a wide performance spectrum. Heating capacities of 12 to 1000 kW, max. possible cooling capacities up to 3460 kW* and pump flow rates of max. 300 m3/h are impressive basic data for these technically sophisticated temperature controllers for operation with compressed water up to 150°C. This series is mainly used for roller temperature control (foils, paper, rubber etc.).

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. All standard units are equipped with an energy efficient constant heating control. Depending on the product version a flow rate measurement and control, whose actual value is indicated simultaneously with the actual and nominal values on the colour screen, is installed as standard or is optionally available. Temperature profiles are graphically indicated after selection of the corresponding menu function. On the start page useful functions like limit value monitoring, leak stop operation etc. can be selected. The proven teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. The 95°C series was extended by three versions with higher capacities. The models are designed for larger consumers; they have heating capacities from 18 to 36 kW, cooling capacities from 50 to 120 kW and pump flow rates from 110 to 170 l/min.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

gwk Gesellschaft Wärme Kältetechnik mbH has advanced the continuous development and modernisation of its range of compact water chillers and adapted it to the changing market requirements in close cooperation with customers. Conversations and customer feedback are the key to our success. Increasing requirements and increasingly efficient production processes are only a few of the features that are more and more important to our customers. Easy operation via touch screen Easy operation via touch screen The proven weco series has been upgraded by the installation of a user-friendly touchscreen with new integrated functions. By a light touch on symbols on the start page useful functions like temperature control, pressure control etc. can be selected. In order to supplement the operational safety, maintenance intervals and advice are indicated in clear text on the service page.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

CLEAN PROCESS WATER WITH GWK KU-PLANTS Water is one of the key elements in our daily life. It is a supplier of the most various requirements, also in the area of technical and mechanical production. Water is an excellent cooling medium. ku-plants from gwk utilise the cooling energy provided by water to carry away heat from production machines in the most troublefree and cost effective way possible. Removing side effects Fresh water from a well, from rivers and from other surface reservoirs is always saturated with oxygen and includes a large number of minerals and suspended particles which can block up the cooling channels in production units through corrosion or by producing deposits. ku-plants from gwk do not allow such problems to arise. A plate-type heat exchanger made of stainless steel separates the clean closed circuit that is used to cool the production from the natural fresh water circuit that is contaminated with all kinds of impurities.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMPTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. In the selection series we used the most frequently selected equipment features and heating performance of the proven premium series advanced. The protemp selection temperature control unit is particularly suitable for the supply of multi-circuit water distributors and is designed for the display of up to 6 external proflow temperature control channels.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

A complete centralised cooling plant, including the required peripherals, can be set up in the absolute shortest possible time at the subsequent place of installation and is immediately ready for use by means of prefabrication and installation in a container. This way, the otherwise high investments for an operating building, the costs for installation and start-up of the plant are reduced. Container cooling plants almost have no limitations in terms of their capacity and variety of possible combinations. They are supplemented by peripheral systems such as water treatment and water preparation systems or compressed air compressors. A series of different cooling systems and the combined systems composed of these units are primarily available: Chiller Heat pump systems for heat recovery Cooling tower combined with a KU system as a closed, clean cooling circuit Air heaters for direct recovery of heat hermeticool-units hermeticool hybrid-units

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The use of direct cooling is always an advantage when a high cooling capacity is requires and the temperature differences between cooling water and circulating water are low. Here cooling water is directly and without temperature loss supplied to the circulation circuit. Absolute reliability, high regulating accuracy, easy operation and a favorable price/performance ratio: apart from the versatile performance features a modern temperature machine has to fulfill, these are the key criteria in the temperature controller wd series.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Temperature controllers of the teco series cd are designed for the operation with water and direct cooling up to 95 °C or 120 °C. The temperature of the process water is controlled automatically. A temperature sensor, installed inside the unit, measures available actual temperature. The microprocessor control with membrane keyboard or touchscreen operation compares measured value and preselect set value and controls heating or cooling. A trouble free operation is guaranteed by a complete safety system.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The multiple water quantity control system in modular design that is available in several versions fulfils not less than three requirements at the same time. It combines the advantages of the conventional water distributors, the impulse cooling systems and the continuously operating temperature control units while eliminating the disadvantages of each of these systems. The temperature control system disposes of up to 128 individually adjustable circuits and is suitable for the processing of polyolefins and technical thermoplastic materials. In case of the basic execution (itd B) the requested flow rate is adjusted manually and is then monitored by a flow meter and presented digitally and graphically on the central display of the control unit. In the standard execution (itd R) the water quantity is individually set for each circuit at the central operating unit and - if necessary - is readjusted automatically via a water quantity regulation valve within adjustable limit values.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow ultrasonic - as a replacement for the current and widely used standard measuring variant with impeller, turbine or vortex - now makes contactless measurement according to the ultrasonic principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. Alternatively, the mechanical flow measurement according to the differential pressure principle is available with the proflow mechanical. Easy to integrate in machines and plant lines 4 or 6 x consumer channels (forward/return) 1/2“ With LED-display on fl ow sensor Temperature measurement PT 1.000 Big RED/GREEN Status LED 1 x main connection 1“ Flow rate each channel 1 ... 30 l/min (no „overload-risk“-> 60 l/min possible]) Operating temperature: 0 ...120 °C

Request for a quoteResults for

Industrial machines - Import exportNumber of results

43 ProductsCompany type

Category

- Plastics - machines and material for industry (29)

- Metal straightening machines (2)

- Potting equipment (2)

- Food Industry - Machines & Equipment (1)

- Milling - machine tools (1)

- Construction - Machines & Equipment (1)

- Electric cables (1)

- Connectors, electronic (1)

- Engraving, industrial - steels and metals (1)