- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-pressure systems

Results for

High-pressure systems - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

We offer grooved seals in many different designs. There are versions without centering rim (center ring), with fixed centering rim and with loose centering rim. The area of apllications is very divers and ranges from use in fittings to high-pressure lines and systems. versions ✔ with strainer insert ✔ with flag ✔ with leakage protection ✔ with webs

Request for a quote

WOMA GMBH

Germany

As well as the standard units, we design and produce individual high pressure water jetting systems in accordance with our customer needs. The configuration is flexible to respective requirements. Whether it is mobile or stationary, with diesel engine or electric motor – our experts find the best solution even for complex applications or problematic work conditions.

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

KAMAT GMBH & CO. KG

Germany

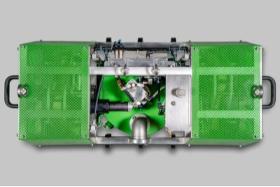

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

KAMAT GMBH & CO. KG

Germany

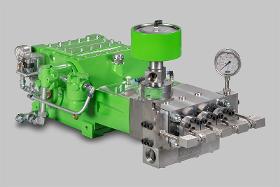

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

F.E.S. GMBH

Germany

Hinged belt filters, also known as folding belt filters, are used for cleaning contaminated coolant fluids in metal processing and rolling mill applications. Cleaned coolant fluids have longer service life, improve the surface quality of workpieces or rolled goods, and assist in heat dissipation at the processing or forming site. Advantages: High throughput capacity No backflushing required during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure flushing system Cost-effective Operation: The F.E.S. hinged belt filter incorporates a circulating plastic filter belt to meet the filtration requirements without disposal issues. A filter belt cleaning device is located below the filtrate discharge chamber. The opening and closing of the chambers are controlled by two pneumatic cylinders. The self-locking toggle lever mechanism keeps the chambers closed even in the event of a loss of compressed air.

Request for a quote

KELVION HOLDING GMBH

Germany

The EGR Cooler, developed in close collaboration with our customers for medium and low speed engines, ensures that the recirculation exhaust-gas is mixed at the lowest possible temperature with the air for the combustion process. EGR Coolers are an essential element of EGR systems for the next engine generation which already now fulfills future emission guidelines according to IMO (International Maritime Organization), EPA (US Emission Protection Agency), EURO, etc. We have developed various cooler designs with regard to the different requirements of EGR Coolers at 2-stroke and 4-stroke engines. The patented design for 4-stroke engines high pressure EGR system enables cooling of exhaust gas, some of which are over 700 °C, down to 50 °C.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball check is open ▪ Simple connection to measuring, control and switching devices Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of sealing material) ▪ For use in conjunction with other liquid media please consult STAUFF Working Pressure ▪ Max. working pressure 400 bar / 5801 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. Materials Metal parts made of: ▪ Steel, zinc/nickel-plated = C6F (CrVI-free) Ball made of Stainless Steel Sealings made of: ▪ P = NBR (Buna-N®) Temperature range -20 °C ... +100 °C / -4 °F ... +212 °F ▪ V = FPM (Viton®) Temperature range -20 °C ... +200 °C...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with piston valve for: ▪ Hydraulic applications with low-viscosity fluids (e.g. water, cooling lubricants, etc.) ▪ For high, pulsating pressures ▪ For customer philosophy “Soft sealing / non metal to metal seal” ▪ Pneumatic applications ▪ Filling (flow in opposite direction) SKK-FÜLL Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems ▪ Filling of accumulators (special filling-version) Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Please pay attention to the sealing materials used) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of ultimate tightness requirements for gaseous media, a special Gas-type is available Working Pressure ▪ Max. working...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with piston valve for: ▪ Hydraulic applications with low-viscosity fluids (e.g. water, cooling lubricants, etc.) ▪ For high, pulsating pressures ▪ For customer philosophy “Soft sealing / non metal to metal seal” ▪ Pneumatic applications ▪ Natural gas applications with DVGW requirement SKK-DVGW ▪ Other gas applications without DVGW requirements SKK-GAS ▪ Filling (flow in opposite direction) SKK-FÜLL Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems ▪ Filling of accumulators (special filling-version) Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Please pay attention to the sealing materials used) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball check is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of seal material) ▪ For use in conjunction with other liquid media please consult STAUFF Working Pressure ▪ Max. working pressure 630 bar / 9137 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. ▪ Joining under pressure up to 630 bar / 9137 PSI max. Materials Metal parts made of: ▪ Steel, black zinc/nickel-plated = C6F* (CrVI-free) Optional: ▪ Stainless Steel V2A (1.4305 / AISI 303) on request ▪ Stainless Steel V4A...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of sealing material) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of ultimate tightness requirements for gaseous media, a special Gas-type is available Working Pressure ▪ Max. working pressure 630 bar / 9137 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. ▪ Joining under pressure up to 400 bar / 5801 PSI max. Materials Metal parts made of: ▪ Steel, zinc/nickel-plated = C6F...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAYFRAN GMBH

Germany

Machine pump back stations are the ideal solution for the transport of swarf and coolant (oil or emulsion). They are easy to retrofit nearly, to all types of machine tools. Crushers must be added at those machines producing long swarf. High pressure systems can be added easily. Swarf and coolant (oil as well as emulsion) will be conveyed through pipes to a central filter or processing plant

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Non-Return Valves WITT non-return valves protect plants, pipelines and outlet points against reverse gas flow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes (up to DN200) and flow rates (0.35 – 106 SCFH). The sophisticated valve technology of WITT non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages, and dirt filters at the inlet point assure long service life of the non-return valves. Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Non-Return Valves WITT non-return valves protect plants, pipelines and outlet points against reverse gas flow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes (up to DN200) and flow rates (0.35 – 106 SCFH). The sophisticated valve technology of WITT non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages, and dirt filters at the inlet point assure long service life of the non-return valves. Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The HL-Druckstrahl-Rücksaug-System for the mobile, dust-free sandblasting of hard / non-dismountable parts, such as steel carriers, running gear or similar large parts. The Mega Clean Master is often used in car body repair shops, shipyards, but also in road and rail traffic. The Mega-Clean-Master is the optimal solution for parts that are difficult to access or can be dismantled, which have strong corrosion or stubborn lacquer parts. Mobile, efficient, dust-free, and thanks to the built-in high-performance print-jet system, the perfect companion for difficult-to-clean parts.

Request for a quote

HAVER NIAGARA GMBH

Germany

Price 24,300.00 € Condition Company HAVER NIAGARA GmbH Location Münster, Germany Your Process Processing Category Minerals Package - Year built 2014 Contact person Bernward Wellerdiek B.Wellerdiek@haverniagara.com +49 (0)251 9793 114

Request for a quote

HAVER NIAGARA GMBH

Germany

The HYDRO-CLEAN® is an innovative high pressure washing system where the dirty raw material is subjected to a rotating water jet generated by a wash rotor. In a processing step the coarse dirt is removed and components that can be slurried are separated from the desired product. Thanks to the rotating washing rotor, the water jet cuts through the material bed and circulates or turns over the raw material inside the washing chamber. The raw material remains in the washing chamber only a few seconds and is subjected to the water jet multiple times. The material is then carried off as slurry, leaves the chamber and is wet-screened. The system’s cleaning performance has proven itself in a number of applications worldwide. To assure an optimum result we offer our customers: material analyses of your product at our R&D Center washing trials with your product at our R&D Center trials with your product on site at your location demonstration trials on an industrial...

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

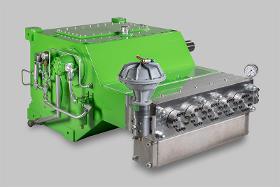

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

Performance in a small space Our compact K100-3 high-pressure three-plunger pump boasts impressive performance data: With only 15 kW of input power, it delivers a pressure of 2000 bar, making it one of the most powerful pumps in its size class. The K100-3 triplex plunger pump really comes into its own when it comes to water jetting for industrial high-pressure cleaning.

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Reducing coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Bend 45° F/F

Request for a quoteResults for

High-pressure systems - Import exportNumber of results

37 ProductsCompany type

Category

- Connectors, plumbing (10)

- Pumps (5)

- Industrial equipment hire (2)

- Piston pumps (2)

- Valves for industrial fittings (2)

- High-pressure cleaning machines (1)

- Filters, liquid (1)

- Engines, internal combustion (1)

- Industrial sprayers for surface treatment (1)

- Refrigeration plants and equipment, commercial and industrial (1)

- Rubber - industrial machinery and equipment (1)

- Sandblasting equipment (1)

- Seals (1)