- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating oil

Results for

Heating oil - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® tank heating units are particularly suitable for the direct heating of liquids (Oil, Water, Emulsions), air and gases. They contribute to the avoidance of paraffin clouds in fuel oil or Diesel storage tanks. In relation to the process, we provide you with tank heating units with tubular heating elements made of stainless steel which we adjust to the respective application situation and the medium to be heated in consultation with you. We offer our series “THF” a suspended, on a chain flexible solution to keep heating oil or diesel fuel in the extraction line pumpable. As a fixed version, we recommend our industrial immersion heaters for heating liquids. Further information about our CSN® Tankheizkörper

Request for a quote

TROTEC GMBH

Germany

IDS 30 OIL HEATER FANMobile heating power on wheels: The IDS 20 D direct heaters for fast, uncomplicated heating With robust design, the oil heater IDS 30 has everything you need for an economic and effective heating application. This device from the IDS pro series is very flexible. On the one hand, its carriage with big wheels enables a quick transport and easy set-up even on building sites and uneven terrain. On the other hand, there is no need for an external oil tank because of the integrated fuel container. The oil heater fan is originally "Made in Europe" and as standard equipped with electronic flame trap, safety thermostat for overheating protection and fully automatic after-cooling. Additionally, the double-walled housing with protective coating increases safety at work by minimizing the surface temperature of the outer casing and thus the risk of injuries and further offers an effective soundproofing.

Request for a quote

TROTEC GMBH

Germany

ELECTRIC HEATER FAN TDS 50 EPowerful mobile heating in a trice The robust electric heater fan TDS 50 E is the powerful heating solution for the building industry and agricultural sector, for the catering trade or holiday home. With its hard-wearing double-walled housing, the TDS 50 E is on the one hand flexibly prepared for different operating conditions, and on the other hand offers good thermal insulation. Designed for a mobile change of location, the heating device can be transported conveniently using the practical carrying handle. Unlike directly fired gas or oil heating devices, the electric heater fan neither consumes oxygen nor produces combustion gases. Therefore, it can be used basically everywhere provided there is a socket – particularly for temperature control in unheated rooms.

Request for a quote

FRIEDRICH SCHULTZE GMBH

Germany

Screw-in heaters are versatile and intended for heating liquid media in industrial and commercial applications. When selecting, the specific surface load permitted for the respective medium must be observed and checked by the customer. EHK G2 are mainly used for heating hydraulic oil in containers in which the replacement of the heating cartridge without draining the medium must be possible. Ceramic heating cartridge in stainless steel tube ø 50mm, material-no. 1.4512 or material-no. 1.4404. G2″ thread SW70 welded from V2A. Terminal box made of PA6-GF30, impact-resistant and oil-resistant, degree of protection IP66/67. Unheated zone 50mm, surface load 1,5 W/cm², voltage 230/400 V. Special versions on request.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 60 DThe integrated fuel tank makes the high-performance direct oil heater fan IDE 60 D our best recommendation for use on construction sites, in halls and so forth! Whether for direct permanent heating in agriculture and production, on construction sites or in storage facilities – there are many typical standard oil heating tasks where sound technology with ideal value-for-money ratio and a high 60 kW heat output is called for. Our response: The oil heater fan IDE 60 D. This ready-for-use heating device is a particularly efficient directly fired oil heater fan and due to its durable housing made of doubly coated material is optimally prepared for various heating applications in well-ventilated areas. In the course of this, the IDE 60 D’s large air outlet ensures a maximum expansion of warm air with a high efficiency level of 100 %.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 80Our most powerful indirect oil heating fan IDE 80 is our recommendation for construction sites, halls, agriculture and workshops! So much hot air for so little money — this is the successful concept of the IDE series which also applies to its currently largest member. The oil heater fan IDE 80 has a heating capacity of 80 kW setting new standards for its own class as well as for heating at construction sites, in workshops and halls as well as in agriculture. The optional flue gas discharge allows flexible use of the indirect-fired oil heater fan IDE 80 for heating enclosed spaces. The IDE 80 is then fired with diesel or fuel oil. Continuous fuel supply to the stainless steel combustion chamber is regulated by means of a high-quality Danfoss injection pump. Among the further assets are the easily accessible, external fuel filter as well as the possibility to easily read the remaining fuel volume at the filling level indication integrated in the tank.

Request for a quote

TROTEC GMBH

Germany

Because the oil heating units come with an integrated fuel tank you won’t need any cumbersome or bulky external fuel tanks, giving you even more freedom and mobility when it comes to choosing the right place for installation. The light yet sturdy undercarriage with extra-large wheels allows you to transport and install the units quickly and easily and because the units are so mobile they can be quickly and easily moved around building sites and over rough and bumpy terrain, even single-handedly if need be. The units’ solid and strikingly simple construction guarentees a reassuringly high level of reliability and a blissfully low level of maintenance. Needles to say safety is always first and foremost with the oil heating units in the IDS Series: The units are standard-equipped with an electronic flame safeguard, safety thermostat for overheat protection and fully automatic aftercooling.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 30Flexible all-rounder for a wide range of heating applications: the ultramobile oil fan heater IDE 30 If you are looking for an equally cost-effective and reliable oil heating solution with clean, dry, warm air for the flexible heating of workshops, storage and production zones, construction sites or halls, the compact oil heater fan IDE 30 is our best recommendation. Owing to its durable housing made of doubly coated material, this indirectly fired oil heater fan is optimally prepared for outdoor heating applications and can further be used for heating closed rooms when applying the optionally available flue gas discharge. The firing of the IDE 30 can variably be made with diesel or fuel oil, the constant supply of which is ensured by a high-quality Danfoss injection pump. The external fuel filter enables an easy access and the current amount of fuel can conveniently be read from the integrated tank filling level indication.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 20Flexible all-rounder for a wide range of heating applications: the ultramobile oil fan heater IDE 20 Hot air in a trice at a low price: The smallest oil heater fan of the IDE series from Trotec comes up trumps if you are looking for a compact and low-priced yet reliable oil heating solution for flexible heating applications. Whether in workshops, warehouses, production zones or on construction sites – with a heating capacity of 20 kW the IDE 20 confidently generates clean and dry hot air in quantities of up to 600 m³/h. Even longer outdoor applications present no obstacle to the oil heater fan IDE 20, because it is provided with a durable housing made of doubly coated material, borne by a smooth-running carriage construction with cable holders and installed fuel tank. When employing the optionally available flue gas discharge, this heating device can also be flexibly used for the fully automatic heating of closed rooms.

Request for a quote

KELVION HOLDING GMBH

Germany

Different applications require different designs for an optimal fit, so we provide Shell & Tube heat exchangers in single tube design with plain, low and high fin tubes and also with compact fin bundles. The plain tube design is most suitable if media have similar heat transfer properties, where the compact fin design means the best possible performance if there is a substantial difference in heat transfer rate, for example when exchanging heat between oil and water. The low and high fin single tube solution is between the previous two designs in order to further optimize on flow, pressure drop and velocities of media.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The higher process temperatures, the higher the technical requirements for the temperature machine. Decades of experience in construction of temperature machines for heat carrier oil applications up to 400°C makes us the preferred partner of many customers for applications of this kind, particularly in the area of pressing and extrusion. Dimensioning of our teco tt/th series up to 400°C is based on DIN 4754. Design and technical configuration of all temperature controllers are based on the requirements of this norm. Exact film temperature calculation ensures, in combination with flow monitoring, efficient and at the same time reliable operation in all operating conditions. A lockable filter in the circulating medium return line is a standard installation; another installed feature is an expansion vessel with a cold oil container for reliable prevention of damage by oxidation due to oxygen accumulation in the heat carrier.

Request for a quote

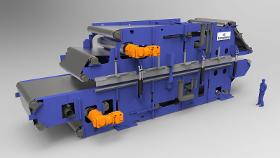

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thermal oil systems are used in countless production processes: the process heat conveyed by using thermal oil is needed in a number of industries. Büttner's triedand-tested thermal oil heaters are heated with ue gas and are designed as single-pass Systems.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

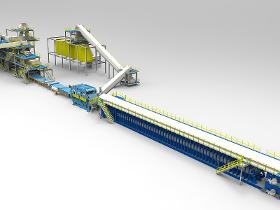

Using a ContiTherm preheater upstream of the ContiRoll® press increases the production output of a wood-processing plant signicantly. It is an additional component integrated into the forming line and serves to preheat the mat before it is transferred to the ContiRoll® infeed to just below the temperature at which the glue starts to cure. A steam-air mix is conveyed through the mat. During this process, the steam condenses at the bres or particles, heating them up. The preheating temperature can be set most accurately by varying the steam content of the mix. The machine is separate into two to four sections (seen in working direction). Depending on the application these sections are designed for a unidirectional or a bidrectional steam injection or equipped with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conveyance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The ContiTherm is the optimally suited for the production of wood-based insulation material, the wood bres being preferably resinated with PMDI or thermoplastic melts. A steam/air mix is conveyed through the bre mat. During this process, the steam condenses at the bres or particles, heating them up. At the same time the gap between the upper and the lower hot platens is precisely maintained. This is essential for the production low-density boards of up to 250 kg/m³ approx. which exhibit outstanding thermal insulating propertie The dew point of the steam/air mix - thus the mat temperature - can be precisely set by varying the steam content. T sections (seen in working direction). Depending on the application these sections are designed for a unidirectional o with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conve

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The thermal incinerator (TI for short) is a system which converts gas or vaporous pollutants found in exhaust gas into non-polluting compounds by way of direct combustion. This machine is characterized by: The thermal incinerator (TI for short) is a proven and robust plant for the conversion of organic pollutants (VOCs, etc.). Today it is used especially for processes which involve high exposure to condensation or dust, or for specialized solutions requiring greater heat recovery potential. An example of this would be exhaust gases containing plasticizers or siloxane. The modular design of the combustion chamber and heat exchanger especially is conducive to servicing and cleaning compared to other designs. The polluted air is forced by means of a centrifugal fan into the tube bundle heat exchanger where it circulates around the tube bundle in a cross-current fashion. The heat exchanger can be designed for an efficiency of up to 70%. The pollutants are converted in the combustion chamber at a temperature of around 760 °C. After extensive heat transfer to the raw noxious gas, the cooled clean gas leaves the plant, where it can be supplied to various heat recovery systems (or a combination of several). The auxiliary burners can be operated with natural gas or propane or light heating oil.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Newly designed slotted jets arranged throughout the entire operating width guarantee constant flow conditions in the drying compartment. Depending on the coating material, the air is heated via hot water, thermal oil or steam in special heat exchangers. Particularly intensive drying is achieved through the high air speed in the jet channel.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Super Screw connectors are available in different versions of textile reinforced rubber abrasion resistant, heat resistant, oil and grease resistant, white FDA, self extinguishing, with textile on the running surface or in stainless steel. Screws are available in either galvanised or stainless steel. Super Screw connectors are inserted in the belt diagonally and from both sides. After the rubber layer is removed, the connector is installed using just a cordless screwdriver or, in underground mining, using a breast drill or pneumatic screwdriver. Super Screw® connectors are pre installed, depending on the belt width, in lengths up to 3,000 mm or in rolls up to 25,000 mm long. A variety of screws is also available for the initial installation of the connectors or as spare parts, plus various cordless screwdrivers, a pneumatic screwdriver, brace, PZ 2 or PZ 3 cross head bits and a magnetic bit holder.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Heating oil - Import exportNumber of results

17 ProductsCompany type

Category

- Heating, domestic - installations and equipment (7)

- Wood veneer - machinery and equipment (2)

- Heat exchangers (1)

- Energy - production plants and equipment (1)

- Heating, industrial - installations and equipment (1)

- Induction heating systems (1)

- Plastics - machines and material for industry (1)

- Transmission belts (1)