- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat energy

Results for

Heat energy - Import export

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

High-Temperature insulating hose (HT hose) protects heat-conveying lines and prevents thermal damage to adjoining parts with a fiberglass and double-coated silicon rubber top layer. The HT hose is available as a self-contained or re-closable sleeve as well as a custom-made mat. The approximate surface temperature of the duct can be up to 500°C.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

CORMIFLEX® tubes are folded spiral-seam pipes made of high-grade steel precision strip. Reaching up to 350°C, their high temperature resistance is predominantly used for exhaust gas routing in passenger car, utility vehicle, RV and marine heating units. CORMIFLEX® PLUS bears additional resistance against corrosion due to salt and other aggressive agents.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Air flow routing tubes are designed to channel different kinds of air to appropriate destinations. If you have a specialized vehicle and need superior flexibility in your air duct tubing, these products lead the industry. CARADUCT® flexible tubes are multi-layer, grooved tubes that are wound from a combination of aluminum and paper layers. They possess a particularly high crushing strength and have very good insulation properties. Through high flexibility and small bending radii, they offer good space usage, particularly when laying out in corners. Dükerrohr is a twin flexible tube distinguished by a particularly high insulation effectiveness to reduce temperature drops in the warm air ducting. Since it is installed outside of the vehicle, it carries additional protection against water and oil splashes.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Heat protection sleeves and mats extend our expertise in protective aluminum flexible tubing to other shapes and uses. Layers of aluminum foil are combined with fiberglass for products that can withstand temperatures up to 750°C.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Heat protection tubes are made by layering several kinds of aluminum alloy foil and other materials, such as fiberglass and plastic with corrugations. The excellent reflectivity of the aluminum alloy on the external surface reflects radiant heat, and its insulating power additionally serves to protect the aluminum flexible tube’s content from heat sources. These products have great flexibility but high dimensional stability, and they can be compressed or extended as required. They can also be fastened or mounted easily by crimping the end fittings.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

By creating specialized aluminum alloys, pioneering new treatments and combining aluminum components with other materials such as paper, plastic and fiberglass, Novelis has become the global quality leader for the transportation manufacturing industry. We have created a range of transportation manufacturing products that provide insulation against heat, sound and gases, high strength so components remain effective under pressure, and superior flexibility for a full range of designs and implementations. Key Novelis aluminum components include heat exchangers, heat protection mats and sleeves, energy absorption elements, hoses, silencers and flexible tubes, including heat protection tubes, air ducts and exhaust pipes. Novelis is a leading supplier of light-gauge, narrow-slit aluminum fin stock (bare and clad) and brazing sheet used in the production of heat exchangers.

Request for a quote

TROTEC GMBH

Germany

When it comes to applications such as fog production, the very powerful turbine in this product series and FS200 fluid pump can be adjusted continuously, being adapted more precisely to individual operating conditions. The item is known for its low fluid consumption, as well as the maximum 100ml per minute. The item is continuously controllable, with reduced dimensions compared to its predecessor. The 40% smaller space-saving solution comes with foldable canister, being extra dense with smoke because of the controllable fluid pump. The item is easily portable because of the narrow passage like a safety ladder, while the intelligent energy coupling of heating, pomp and turbine is also possible, ensuring a constant thick fog, without any reheating induced disruption. FS200 - the technical data: Fog time at max. level: approx. 210 s Fog time at medium level and below: permanent fog Compressor performance: 1,500 W Fan turbine performance: 1,600 W

Request for a quote

ANTHERMO GMBH

Germany

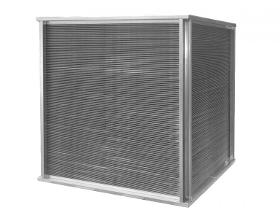

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down. Following to this the braking resistor converts the stop energy into heat. Electrical drive systems are being used more and more on ships, oil rigs, crane barges and offshore vessels of all types. An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy. The Braking Resistor Units from Klöpper Therm are designed according to specific applications.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. All standard units are equipped with an energy efficient constant heating control. Depending on the product version a flow rate measurement and control, whose actual value is indicated simultaneously with the actual and nominal values on the colour screen, is installed as standard or is optionally available. Temperature profiles are graphically indicated after selection of the corresponding menu function. On the start page useful functions like limit value monitoring, leak stop operation etc. can be selected. The proven teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. The 95°C series was extended by three versions with higher capacities. The models are designed for larger consumers; they have heating capacities from 18 to 36 kW, cooling capacities from 50 to 120 kW and pump flow rates from 110 to 170 l/min.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Heating technology with a future The calculation is simple, the technology successful. Efficient surface drying is achieved with biomass in Rippert plants. Together with the Hargassner company from Austria, a specialist for heating with biomass, and the proven Rippert plant know-how, the technology is now marketable and has gone into production. The demanding drying characteristics in a powder-coating plant are compatible with the process and work perfectly. A future-orientated heating technology with considerable economic and ecological benefits – the experts are unanimous in that. Wood pellets or wood chips are the inexpensive energy suppliers. They are valuable waste products that result from the processing of domestic timbers. Heating with wood chips – without intermediate heat transfer media such as thermal oil • Environmentally friendly and CO2-neutral • fully automatic boiler cleaning and ash discharge Maximum financial saving potentials are realised with this energy carrier. Wood chips, chopped to a transportable size and dried by the supplier, are stored in the storeroom near the plant. It can be located on the same level or lower. A tried-and tested transport system consisting of a floor agitator with springs and discharge auger carries the wood chips reliably into the plant. Here it acts as a fuel with maximum convenience. If the calorific value equivalents are examined, we see that 1,000 litres of fuel oil is equivalent to 12 m³ of wood chips. The ratio is the same for 1,000 m³ of natural gas. Heating with wood pellets - without intermediate heat transfer media such as thermal oil Wood pellets are true energy bundles. They consist of natural wood and are made by compressing sawdust, which is produced in large quantities every day in the industry. As a biomass they are the alternative to wood chips and are just as advantageous from an economical point of view. Pellets have the smallest volume and are conveyed dust-free and without odours from storage containers to a storage vessel next to the plant. They are transported into the combustion chamber via a rotary vane feeder and feed auger. For comparison: 1,000 l fuel oil = 2 t pellets 1,000 m³ natural gas = 2 t pellets 1,000 l liquefied gas = 1.32 t pellets Advantages • Reduction in energy costs Heating cost comparison (reference = 1,000 l fuel oil)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Various heater types available, eciency and robustness characterise directly heated drum dryers by Büttner. They are used for drying wood particles, strands, sugar beet pulp and all free-owing types of wood, biomasses and bulk solids Features Water evaporation capacity of up to 80 t/h depending on the product Direct heating system with multi-fuel burners in combustion chambers Direct heating system using ue gases from energy plants Direct heating system using waste gases from turbines or engines All combinations of these types of heaters are possible. A ash tube may be used for pre-drying and oversize separation of material that is quite moist. Material separation via cyclones or drop boxes Function The material to be dried is admitted through an air-tight rotary air lock into a rotating single-pass drum dryer. The dryer drum can be tted with specic internal ights to suit the material to be dried. This results in an increase in surface area and thus an increase in eciency

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The powerhouse among our ContiRoll® impresses by its robust design and well-tuned components. This enables to build extremely long plants equipped with even more powerful motors and more resilient roller rod chains. There are no concessions to be made to excellent board Qualities! Features Patented exible press infeed to ensure an optimal evacuation of air and direct heat transfer Optimised energy consumption in the partial-load section by using the EcoDrive Innovative process control technology to ensure a self-governing operation High-quality hot platen material makes wear plates superuous thus ensuring a direct heat transfer Foundation beams, frame unit and hot paten of the press have dierent thermal dilatation. An advancing speed of up to 2000 mm/s Pressure proles adjustable in longitudinal and transversal directions

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

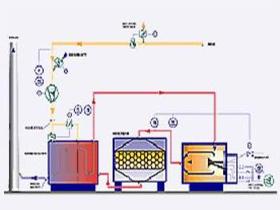

Under defined conditions, the catalytic thermal oxidizer (CTO) is an economical alternative for cleaning organic air pollutants (including VOCs). The system has proven to be particularly efficient when handling identifiable and consistent pollutant loads. In general, exhaust gases containing silicon and phosphorous cannot be treated. Under defined conditions, the Catalytic Thermal Oxidizer (CTO) is an economical alternative for cleaning organic air pollutants. The procedure is based upon the fact that under suitable conditions, even low amounts of volatile pollutants can be burnt without producing residue. This process would have required a high amount of heat energy. Therefore a catalyser and a heat exchanger are installed. The tubular heat exchanger installed behind the catalyser uses as much energy from the hot clean gases as possible in order to heat up the cold raw gases. The job of the catalyser is to decrease the amount of energy required to convert the pollutants without being depleted during the reaction. The raw gas loaded with pollutants is then forced into the heat exchangers of the CTO by the process fan. Here the raw gas is pre-heated by the hot clean gas. When required the burner heats up the exhaust gas further in the combustion chamber to the ignition temperature of the catalyser. In the catalyser the pollutants are converted into non-polluting CO2 and H20 vapour. After the catalyser, the clean gas is forced into the heat exchanger tubes. Along the way through the heat exchanger tubes the raw gases is heated and cooled. Eventually the clean gas leaves the system via the clean gas socket.

Request for a quoteResults for

Heat energy - Import exportNumber of results

16 ProductsCompany type