- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding - steels and metals

Results for

Grinding - steels and metals - Import export

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We offer a wide variety of grades with various dimensions and grain sizes of abrasive belts that are perfectly suited to your application and processes. We will be happy to advise you to find the right sanding belts for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

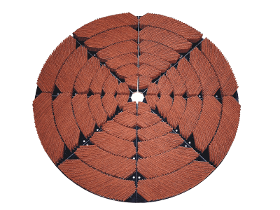

The further development of our deburring grinding plates are our patented deburring segments FAPI-FLEX-SAT (patent no. DE20304860 U1). These advanced deburring segments were developed in collaboration with the company Timesavers from the Netherlands. Fast, safe and clean deburring or edge rounding of sheet metal parts is no longer a problem when using these tools. Deburring grinding segments can also be individually adapted depending on the application. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI-ATTACK sanding disc is ideal for extremely aggressive sanding work and is primarily used for aggressive sanding on the surface as well as on the edge. We would be pleased to advise you on which grinding disk can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs from the FAPI-TRIM series are the ideal tool for deburring on automatic deburring machines (e.g. Weber deburring machines) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-M14 125 series are the ideal tool of hand operated deburring. The integrated M14 thread can be adjusted to regulated angle grinders and are especially fit for smaller and medium series, in which the purchase of an automatic deburring machine is not worthwhile. We would be pleased to advise you on which deburring discs can be used in your processing, in order to attain top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-FIT150 series are the ideal tool for deburring on automatic deburring machines and are particularly suitable for machining larger series. Various deburring machines are equipped with right- and left-rotating deburring discs. For this purpose we offer you our FAPI-QUICK-FIT ADAPTER! The combination of the quick-clamping system and our FAPI-QUICK-FIT ADAPTER also enables simple mounting and positioning of the deburring discs FAPI-FIT150 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-250 series are the ideal tool for deburring on automatic deburring machines (e.g. Loewer DiscMaster 4TD) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-150 series are the ideal tool for deburring on automatic and manual deburring machines (e.g. our deburring machine FAPI-STARGRINDER) and are particularly suitable for processing larger series. The 25 mm bore and 4 driver holes enable easy assembly and positioning of the FAPI-150 deburring grinding disk on the deburring machine. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-125 series are the ideal tool for deburring on automatic, stationary deburring machines and are particularly suitable for processing larger series. The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application. Product features Ultra-fast setup times The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. The selection of different densities, fill lengths, abrasive cloth and abrasive fleece types can have a decisive influence on the deburring process. The optimum design of the deburring discs FAPI-125 can be determined from the process parameters dry or wet grinding, the material to be processed, the material thickness and the desired surface quality or roughness depth. We will be happy to advise you in order to find a suitable deburring disk for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

INDIVIDUAL SOLUTIONSIf you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required. ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units. THE BENEFITS AT A GLANCE Individual mass finishing solution Modular system Choose from electromechanical or hydraulic system Partial automation possible

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

CONTINUOUS TROWALIZING OF NON-SENSITIVE PARTS The AV range of continuous units allows you to continuously process large quantities, with no need to interrupt the mass finishing process to add new workpieces. Thanks to the trough-shaped work bowl, you can process small and medium non-sensitive mass-produced parts (punched parts, die-cast parts, etc.), as well as larger parts (oil tanks, cylinder head covers, etc.). THE BENEFITS AT A GLANCE Continuous workpiece processing Interruption-free workpiece loading Trough-shaped work bowl Easy to integrate in fully automated mass finishing processes Simple material handling without batch loading

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Cleaning discs FAPI-CLEAN provide very good results when grinding and cleaning metal, stainless steel, wood or plastic and can therefore be used as a preliminary stage for grinding/polishing. We will be happy to advise you by telephone or at your site whether the use of cleaning discs FAPI-CLEAN also makes sense in your company for your processes. Construction Cleaning discs FAPI-CLEAN consist of knitted nylon threads which have been soaked in synthetic resin and gently cured. They are available on fabric plates and for use on straight and shaft grinders. Applications The cleaning discs are suitable for cleaning and polishing all surfaces. Scratch-free removal of paint, rust, scale and welding spots from metal Cleaning wood and plastic Remove paint from wood Free stainless steel from blue colouring Dimensions For cleaning discs FAPI-CLEAN the principle applies that they may only be used in conjunction with a clamping shank. Notice: For cleaning discs, the principle applies...

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stainless steel gas springs function the same as their common hydraulic counterparts, but give an alternative when operating under rough conditions such as off-shore and other outdoor exposure applications. Other commons application areas for stainless steel gas spring include health care products, food industry and medical devices.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Grinding - steels and metals - Import exportNumber of results

17 ProductsCompany type