- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- generator systems

Results for

Generator systems - Import export

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

grid | power V M is a closed lead-acid battery specially designed for critical and safety applications such as UPS systems of power generation companies. This product can also deliver very high amounts of energy in ranges of 1min-5h thanks to its high current compatible grid design. In addition, a custom battery rack is included for your critical application and will be approved for you along with the battery. The DIN compatible batteries are transparent (maintenance facilitation) and easy to replace because they fit dimensionally in standard DIN cabinets. The grid | power V M battery is approved according to IEEE and KTA.

Request for a quote

VKF RENZEL GMBH

Germany

Are you planning a gala or would you like to equip your entrance area with a personnel guidance system in general? Then the "Chrome" barrier stand with its high stability is a very high-quality alternative. Hang up a barrier cord if required and simply release it again. The angular knob is, in addition to the chrome-plated surface and the heavy base, another individual feature of the "Chrome" barrier stand.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down. Following to this the braking resistor converts the stop energy into heat. Electrical drive systems are being used more and more on ships, oil rigs, crane barges and offshore vessels of all types. An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy. The Braking Resistor Units from Klöpper Therm are designed according to specific applications.

Request for a quote

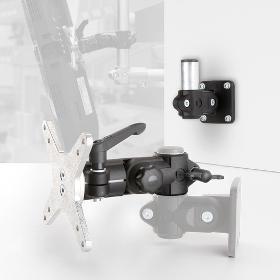

RK ROSE+KRIEGER GMBH

Germany

RK monitor mounting – high-strength, flexible and individually adaptable VESA or universal mount for connecting monitors, displays or control panels. Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too. Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

CANopen has been developed by the members of the international user and producer assosiation CAN in Automation (CiA). The CANopen application layer defines different communication services and protocols (e.g. process and service data) as well as a network management. CANopen is mainly used as an embedded network in machinery, but also as a general industrial communications system. It is based on the international standards ISO 11898-1 (CAN protocol) and ISO 11898-2 (fast physical layer). The CANopen application layer has been standardized by the CENELEC and is defined in the European standard EN 50325-4.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRONG MAGNETS GMBH

Germany

Neodymium block magnet, also known as rectangular magnet, square magnet or bar magnet, compared with disc magnet, block magnet is not as commonly used as disc magnet, but their straight line and clean edge offer a pleasing and different visual appearance, what's more, it provides a bigger surface area than disc magnet of same diameter. Block magnet is usually magnetized with north and south pole on opposite square faces, also a multi poles magnetized block is possible with a new magnetizer machine. Block magnet is widely favoured for clamping applications, magnetic sweeper applications, magnetic separators in the food industry, wind turbine generators, flow control systems & water conditioning application and other related industrial applications.

Request for a quote

TAS SCHÄFER GMBH

Germany

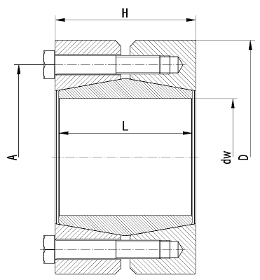

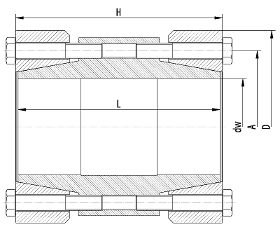

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quote

TAS SCHÄFER GMBH

Germany

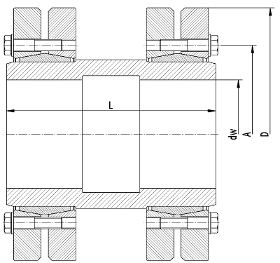

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

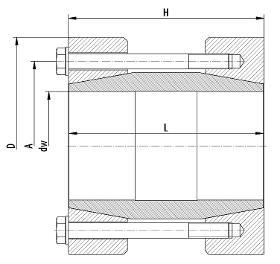

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

PROCOM GMBH

Germany

Why optimization? With the transformation of the energy system a generation portfolio has to be adapted constantly to new conditions. The more generation units are involved and the more commodities and markets have to be observed, the more difficult the management gets. An optimization solution helps to monitor all aspects of cross-function planning and to utilize the resulting market opportunities in optimal fashion. Brief description BoFiT Optimization is an instrument which maps your generation or trading portfolio into a mathematical model. Based on this model optimization tasks can be formulated and calculated for the various business processes. On the one hand, it allows investment planning, on the other hand, trading flexibilities can be optimized at short notice vis-à-vis current markets. Market channel optimization is possible, as is the evaluation of contracts or recalculation of portfolio performance. The model is created graphically, and no specialized mathematical...

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

Our combined turned-milled parts which are produced fully automatic on CNC machining centers are used in general mechanical engineering and actuator systems.

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® scalper is the best choice for crushing plants or the classification of coarse and difficult-to-screen materials at high throughput rates and fluctuating material feed rates. The unique NIAGARA® drive system generates a constant circular vibration motion at a fixed amplitude. The amplitude remains unchanged over time, no matter what the material load is. The application area of the NIAGARA® Scalper covers a variety of industries and materials with a length of up to 2000 mm and a cut size of 2 - 450 mm. Advantages reduced loads and energy demands for the subsequent crushing plant increased crusher capacity maximising the quality of the crushed product quick and easy re-balancing is always possible built with long-life bearings maintenance-friendly, modular machine design dynamically balanced construction modernisation of existing plants, performance improvement You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteResults for

Generator systems - Import exportNumber of results

14 ProductsCompany type