- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gauge

Results for

Gauge - Import export

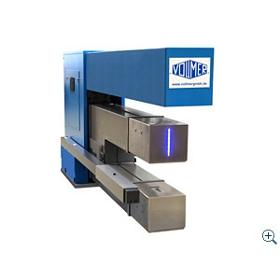

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Without aluminum, the entire supply chain could break down and become inefficient. Aluminum packaging is part of the solution and essential for sustainable growth. Light-gauge aluminum is unsurpassed as a reliable and versatile packaging material, and it is ideal for protecting food, pharmaceuticals and other products from light, oxygen, moisture and contamination. As a global leader in aluminum rolling and specializing in coil-coating, laminating, tray and container production, Novelis offers a range of products to satisfy practically any customer request. That’s why our aluminum packaging solutions are used for food containers, bottles and cartridges worldwide.

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Display of DMS sensors 8 programmable parameter sets Up to 4 alarm outputs

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Weight Force Pressure Torque For signals from the Ex area LCD display with plain text Digital interface

Request for a quote

INFICON GMBH

Germany

The INFICON Pirani Gauge Display PGD400 in combination with the INFICON Pirani Standard Gauge PSG5xx provides a cost effective pressure monitoring solution. Although it is called Pirani Gauge Display the PGD400 also supports our PCG55x and MPG series vacuum gauges.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6HS – s615 is a heat treatable product specifically designed and optimized for high strength requirements. This product offers an excellent balance of properties: superior formability in the as-supplied temper, high in service strength and excellent bending and crash behavior. Novelis Advanz™ 6HS – s615 has a wide array of applications for general structure and crash energy absorption such as engine supports, cross members, transmission tunnel and front and rear crash members. The product shows excellent formability and bake hardening response. Due to its superior in-service strength, this alloy is ideal for down-gauging both skin and structure components. All values listed are typical.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6HS – s600 is a heat treatable product specifically designed and optimized for high strength requirements. The product shows good formability and bake hardening response. Due to its superior in-service strength, this alloy is ideal for down-gauging for structural applications. The product shows good formability and bake hardening response. Due to its superior in-service strength, this alloy is ideal for down-gauging structure components. All values listed are typical.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6HS – e600 is a heat treatable product specifically designed and optimized for high strength requirements. The product shows good formability and bake hardening response. Due to its superior in-service strength, this alloy is ideal for down-gauging skin components. This product can be used for hoods, fenders and roofs. The product shows good formability and bake hardening response. Due to its superior in-service strength, this alloy is ideal for down-gauging skin components. All values listed are typical.

Request for a quote

INFICON GMBH

Germany

The INFICON Vacuum Gauge Controller 031 (VGC031) is designed for use in conjunction with the INFICON Pirani Gauge Enhanced 050 (PGE050) and acts as a convenient power supply, control and readout. VGC031 and PGE050 are a flexible combination to monitor your vacuum system in the range from 1.3 × 10 -4 up to 1333 mbar (1 × 10 -4 up to 1000 Torr). The VGC031 with its space saving panel mount housing supports a variety of technical features as 2 set point relays, 4 user selectable analog outputs and offers additionally RS232/ RS485 digital interfaces. The bright, sharp and clear OLED display with the integrated keypad user Interface rounds out this user friendly vacuum gauge controller package. The rugged industrial design makes the VGC031 in combination with the convection enhanced PGE050 gauge sensor a very good choice for many vacuum applications were economical vacuum measurement from low to high vacuum range is required. VGC031 controller and PGE050 convection enhanced vacuum...

Request for a quote

INFICON GMBH

Germany

Sustainable solution for process measurement, control and data log Compatible to the wide range of INFICON active gauges, the new VGC50x series of active gauge controllers are able to monitor and data log the entire pressure range from 10⁻¹⁰ to 1500 mbar (10⁻¹⁰ to 1125 Torr) and the set point status. 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 5×10 -4…1500 5×10 -4…1500 5×10 -4…1500 5×10 -10…1500 5×10 -10…1500 5×10 -10…1500 mbar, Torr, Pa, hPa, Micron, V mbar, Torr, Pa, hPa, Micron, V mbar, Torr, Pa, hPa, Micron, V

Request for a quote

INFICON GMBH

Germany

The INFICON Vacuum Gauge Display VGD500 connects to our CDG product line to provide a 4 Digit Display. It`s a small unit which Displays the pressure of the gauge. The pressure reading is selectable in pressure unit Torr, mTorr, mbar and Pa.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

The module µCAN.1.sg-SNAP is designed to acquire strain gauge measurement signals such as forces, torques, sequences and voltages and transfers them via CAN.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

The µCAN.1.sg-BOX is a decentralized CAN module for the acquisition of strain gauge or resistance bridge signals. The CAN interface supports the protocol CANopen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

The µCAN.4.sg-F1 is the universal measurement module for the acquisition of analogue standard signals. The module is equipped to measure strain gauge full brigde signals in four-wire technology at an adjustable sample rate of up to 1 kHz per input (4 kHz overall sample rate). The bridge is excited directly from the module with a ratiometric measurement.4-wire technology.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

The µCAN.4.sg-BOX is a decentralized measurement data acquisition module for the acquisition of four strain gauges or resistance bridges. The resistance bridge data is acquired at a total sampling rate of 400 Hz.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Reliable sludge blanket measurement via optical sensor The sludge level meter OPTISYS SLM 2100 features an accurate and reliable profile measurement of the sedimentation tank using an optical sensor which travels through all layers of the tank reading suspended solids concentration at the different heights. — Optical measuring system for sedimentation profile measurement — Continuous level measurement of sludge blanket (zone tracking) — Common operating and service concept with other KROHNE devices

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Adjustable Gauge Fitting EMV ▪ Fixed mounting of a pressure gauge without a test coupling ina existing port connection Materials - Metal parts made of: ▪ Steel, zinc/nickel-plated = C6F (CrVI-free) ▪ Stainless Steel V2A (1.4305 / AISI 303) or V4A (1.4571 / AISI 316Ti) on request Sealings made of: ▪ P = NBR (Buna-N®) or V = FPM (Viton®) Gauge Adaptor SMA Direct Gauge Adaptor SMD

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Reflexion level gauge type 410- PN16-40- with frontally welding ends Ø 20 x 2,6 operating pressurre max. 35 bar Use: This sightglasses suitable for visual inspection of liquid levels in the tank, they enable reliable monitoring of the level.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Reflexion level gauge type 411- PN16-40- welding ends Ø 20 x 2,6 operating pressurre max. 35 bar Use: This sightglasses suitable for visual inspection of liquid levels in the tank, they enable reliable monitoring of the level.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Gauge Isolator Valves SWS-S1 (Single Station) ▪ Effective protection of pressure gauges against overload caused by pressure peaks ▪ Suitable for panel installation ▪ Push button to read and turn to lock ▪ Multilingual instructions printed on face plate ▪ Maximum working pressure: 400 bar / 5800 PSI Gauge Isolator Valves SWS-A1/A2 (Single Station) ▪ Effective protection of pressure gauges against overload caused by pressure peaks ▪ Designed for in-line assembly (type A1) or 90° assembly (type A2) with female BSP / male BSPT, female NPT / male NPT or female NPT / male SAE threaded connections ▪ Panel mounting nuts available on request ▪ Rotating swivel nut allows for accurate orientation of the pressure gauge ▪ Maximum working pressure: 400 bar / 5800 PSI

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Gauge Isolator Valves (Multi Station) SWS-M ▪ Pressure measurement on six positions in the hydraulic circuit with only one pressure gauge ▪ Suitable for bulkhead installation ▪ Turn button to select position of measurement ▪ Multilingual instructions printed on panel ▪ Maximum working pressure: 400 bar / 5800 PSI

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thickness measuring systems THICK-SCAN behind the ContiRoll® optimizes the process and to reduces the costs while, at the same time, assuring the quality standard. If the gauges are located in the sanding line, the tool life of the sanding belts is enhanced and the quality is assured. The time is long past since panel thickness tolerances have been measured during production by handheld devices. Today, however, such measurement is carried out continuously online. In the majority of plants, quality control is not the rst priority for new investment for online thickness measurement. The current trend is to achieve the enormous potential savings in wood raw material, resin and energy consumption. If the upper tolerance level is exceeded, valuable resources are wasted. The Thickness Gauge prevents such losses. It is robust and reliable.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Finding out the unrealized potential through the use of weight per unit area gauges One of the most vital factors in the production of wood panels is the constant spreading of material. If tolerances are exceeded, higher material and energy consumption are the consequences. MSX, which constantly moves back and forth across the mat before it enters the hot press, maintains tolerances within the optimum range. The result is homogeneous forming in lengthwise and crosswise directions. The enormous technical developments of “Weight per Unit Area Gauges” of the past years are physically not visible. What are the previous limitations of weight per unit area gauges? The x-ray tube needed a cooling device. This resulted in a reduced lifetime. Electronic Wood Systems developed a detector with extremely high sensitivity – probably unmatched in the world. Due to this new detector the net power could be reduced to a small portion of the permitted power.

Request for a quote

OGE GROUP

Germany

Tubular Level Gauge - Instruments, Connections & Compensators

Request for a quoteResults for

Gauge - Import exportNumber of results

37 ProductsCompany type

Category

- Measurement - Equipment & Instruments (8)

- Electronic data processing - microcomputers (5)

- Gas and oil - exploitation (4)

- Cars - electrical and electronic parts and components (3)

- Wood veneer - machinery and equipment (2)

- Sensors (1)

- Precision measuring instruments (1)

- Standard gauges (1)

- Trays and dishes, aluminium (1)