- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gaskets

Results for

Gaskets - Import export

IBK WIESEHAHN GMBH

Germany

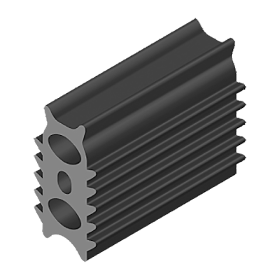

Developed by IBK Wiesehahn, the secondary friction connection seal with H-profile has created an area of application in the industrial branch. The successfull conzept of “secondary friction connection” is based on the separation of bracing and sealing. Every functionary of the seal meet only one function. The seal is made of hard metal-profile and elastic sealing-material. The sealing-material is measured, that after reaching the block storage, the recovery behavior fully exists. A overpress of the sealing-material is basically excluded. Benfits of IBK SAFE-H® Seal: Secondary friction connection (block storage) Seal is chambered (secured against exhaust) High resilience of the flange connection Indenpendently pressure stage dimensions Easier to install regarding centring gauges Simplified warehousing High temperature resistance (up to 1000°C) High pressure resistance (up to 525 bar) Possibility of redefinition of the sealing zone with repair set

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

MINEON HANDEL GMBH

Germany

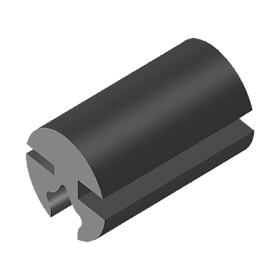

Sponge Foaming square sealing strip,with 3M tape,different sizes available.

Request for a quote

MINEON HANDEL GMBH

Germany

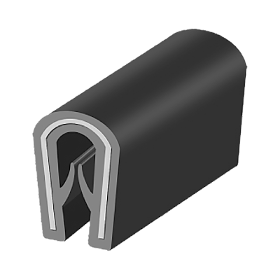

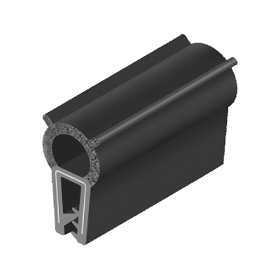

PVC profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

MINEON HANDEL GMBH

Germany

EPDM profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

MINEON HANDEL GMBH

Germany

Sponge Foaming square sealing strip,with 3M tape,different sizes available.

Request for a quote

MINEON HANDEL GMBH

Germany

EPDM profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is the parts used for printer accessories.

Request for a quote

KELVION HOLDING GMBH

Germany

Our gasketed plate heat exchangers combine passion, scientific curiosity and technological expertise. The facts: High efficiency at low operating costs, versatile application possibilities with lower investment costs and maximum flexibility. Our efforts to continuously develop the gasketed plate heat exchanger-series further are aimed at meeting your thermodynamic and hydraulic performance needs and to ensure maximum economic efficiency. Our wide range of plate corrugations, connection sizes, materials, plate lengths and widths enable an ideal configuration according to your exact requirements. Additionally, our gasketed plate heat exchangers come with a maintenance-friendly assembly and sealing technology, ensuring low service and maintenance costs.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

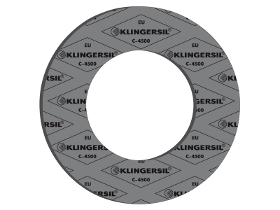

Flange gaskets made of Klingersil C4500 - DIN EN 1514-1 IBC Use: Special high-pressure gasket for alkaline media with very high temperatures and hot steam. Carbon fibers and special heat resistant additives bonded with NBR. High-tech material, especially in strongly alkaline media and in the steam area. Fire safety according to API SPEC 6 FA. DIN-DVGW permit, BAM tested, KTW recommended, certified TA-Luft.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flange gaskets made of Klingersil C4400 - DIN EN 1514-1 IBC Use: Universal high-pressure seal in many areas of food processing and drinking water supply. Very high standard of performance. Aramid fibers bonded with NBR. Resistant to oils, water, steam, gases, salt solutions, fuels, alcohols, organic and inorganic acids, hydrocarbons, lubricants and refrigerants. DIN-DVGW permit, BAM, VP-401 tested, KTW recommended, TA-Luft

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. Product Range: - DVGW tested, see separate brochure - Punched, cut seals - Plates, foils - Semi-finished items - Form articles Benefits: - Highest chemical resistance - Insoluble and does not swell in organic or anorganic solvents - Resistant to the weather - Temperature range -190 to +250 °C - Highly anti-adhesive, does not stick - Resistant to hydrolysis Common fillers: - Quartz - Glass - Carbon / Graphite - Bronze - or without filters Fillers reduce the cold flow, lead to higher resistance to temperature and media, improve thermal conductivity and increase resistance to abrasion and pressure levels.

Request for a quote

IBK WIESEHAHN GMBH

Germany

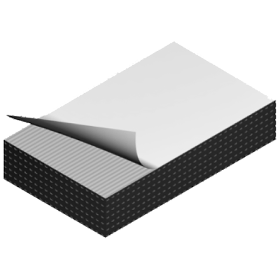

Graf-Flex-SP2 seals The Graf-Flex-SP-2 seal is a pointed sheet seal produced by a special process. The design of the seal is based on empirical values. Numerous tests have been carried out to verify the adhesion between the pointed sheet and the graphite coating as well as the surface quality, and thus the adhesion between the coating and the flange surface.The first phase of these tests led to special perforation of the carrier plate in terms of the geometric shape of the hole and hole distribution. The second phase took account of the adhesion of the seal to the surface of the flange and defined the surface quality of the graphite material. The values found in this way were transferred to the mass production process using a special procedure. . This consisted of a specially produced perforated roller for penetrating the sheet together with a special surface roller. Finally, the graphite coating is applied to the defined surface in the calendering process.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Elastomers are macro-molecular, organic substances with little cross-linked structure. As a result, they do not melt, are insoluble, partly subject to swelling and are elastic. Elastomers are based on rubber which is processed into various kinds of synthetic rubber, depending on the monomer. The various kinds of synchetic rubberdiffer slightlys in their properties so that they are used for different applications with regard to temperature, hardness, elasticity etc. In addition to generally common mouldings such as Orings, our delivery range also includes customized mouldedarticles, profi le cords, punched or cut seals manufactured to specifi cations or to drawings, plates or rollers. Elastomer materials: - NBR - EPDM - CR - CSM - FPM - VQM - NR - EPDM

Request for a quote

HEBMÜLLER GMBH

Germany

We supply molded seals and special elastomer components made of special compounds based on ACM / AEM, NBR / HNBR and FKM / FPM for various hydraulic applications in mechanical engineering.

Request for a quote

HEBMÜLLER GMBH

Germany

Traditionally, our rubber-to-metal seals are used in the engine and transmission sectors, often with the elastomer FKM / FPM.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CINCHSEAL EUROPE GMBH

Germany

We manufacture ready-to-install standard and special flat gaskets in large and small series. Depending on the area of application, different materials are used. Flat gaskets are mostly static and are mainly installed between two flanges in apparatus and pipeline construction. Depending on the quantity and size, the most economical manufacturing process is used.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

The spiral-wound gasket is the ideal gasket for applications with high pressure and temperature requirements. Used in pipelines and apparatus in the chemical, petrochemical, oil and gas production and transport industries, as well as in valves and pumps. Due to the V-shape of the metallic winding strip, the spiral-wound gasket is the only gasket with appreciable recovery, even after long periods of operation.

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Using the materials mentioned, HEUTE+COMP. manufactures sealing elements and O-ring supports according to your specifications. PTFE support rings prevent high pressures from extruding O-rings into sealing gaps and damaging the rings as a result. Due to its cold flow characteristics and high degree of abrasion, pure PTFE is only conditionally suitable for sealing. Accordingly, a wide range of PTFE compounds have been developed to account for all involved parameters. Temperature Media influence Pressures Sealing gaps Assembly conditions Additionally for dynamic applications: Material and surface of the sliding counterpart Speed The technique used to process a material also influences its properties. For instance, a material filled with glass can be made gas-tight through special heat treatment. For this reason, our team offers consultancy early on during the development phase in order to select appropriate materials for your application.

Request for a quoteResults for

Gaskets - Import exportNumber of results

22 ProductsCompany type