- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishes

Results for

Finishes - Import export

JOSEF JASPER GMBH & CO. KG

Germany

We manufacture crystallisers from stainless steel in all dimensions. Our main focus is on exact compliance with the required roughness of the surface and a strict separation of our production areas steel and stainless steel.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Technical plastics for industry are a further speciality of IBK. We produce plastic parts to your specifications (ISO, CAD, drawing) for all temperature ranges and with specific chemical resistance. Whether unusual, complex or just simple forms – we turn, inject, saw, drill or mill, whatever you require. We supply semi-finished products as round bars, plates, pipes, rods, profiles or individual cuts, rolls, rollers or wheels with or without coating. Furthermore finished parts, such as protective systems for safety at the workplace in electronic applications. We process all types of plastic, from polyamide to hard PVC through to GRP/FRP. Semi-finished parts: Plates, Blocks, Full rods, Hollow rods, Pipes, Cut pieces Finished parts Cut and processed (turned, milled, drilled etc.) to drawing, sketch or sample, such as - Wheels, Rollers, Bearing bushes, Thrust rings, Bands, Sleeves, Strips

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EFFICIENT CLEANING – INTUITIVE, ROBUST AND SEMI-AUTOMATIC IF REQUIREDWith a basket centrifuge from the ZM range, you get a robust and easy-to-operate unit for cleaning up to 1,000 litres of process water per hour. Separate up to 14 litres of sludge in a single cycle! The sludge basket is removed and emptied manually. A PLC is available for semi-automatic operation. CENTRIFUGES IN TWO CONFIGURATIONS The ZM basket centrifuge is available in two configurations to meet your requirements. The ZM 03-ECO 1 is perfectly suited for use on a single mass finishing machine in standard applications and island solutions. For two to three mass finishing machines, the ZM 03-FL is the ideal choice. You can of course retrofit application-specific options like a pump station and recooling unit. THE BENEFITS AT A GLANCE Centrifuges with up to 2,012 times the acceleration of gravity Up to 14 l (19 kg) of sludge per cycle Up to 1,000 l of process water per hour PLC for semi-automatic operation

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

!!!Not suitable for drying animal or vegetable products!!! VIBRATION DRYINGThe G-series dryer gently circulates your workpieces by means of vibration, together with the drying medium. The heated drying medium absorbs the moisture from your workpieces. In addition to drying your workpieces, the relative movement between them and the medium also has a polishing effect. PROTECTING YOUR SENSITIVE PARTS The bowl channel pitch is helically shaped and has no ramp, making the G dryer especially gentle when handling your workpieces. The high heating power is fully adjustable. The heater with replaceable heating elements is assembled separately from the vibrating section. To ensure your working environment is protected from dust, the dryer can also be fitted with a dust extractor.

Request for a quote

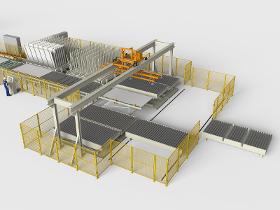

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

This is where the nished boards are sorted by quality and stacked for transport. Features, function The nished boards are transferred from the nishing line, centred, taken up by a suction carriage and placed in dierent stacks depending on the quality assigned in the nishing line. A horizontal transfer carriage picks the stack up and transfers it to a transfer stack. It can be removed by a forklift truck from here. Advantages The options also permit a top and bottom protection board to be put in place without this having an impact on plant performance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are trimmed, cleaned, checked and (if necessary) cooled in the nishing line. Features, function Any excess material caused by the decorative paper being larger than the carrier board is removed from edges on the nished boards in the edgetrimming unit. Rotating brushes then remove any residues that are clinging to the surface. A member of sta will visually assess the quality of the coated board on both sides at the inspection station. The boa station so that it can be inspected from the bottom. The board is then placed in the stack appropriate for its quality Advantages The modular design allows basic modules and optional modules to

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EXTREMELY GENTLE PROCESSINGRotating barrels offer a cost-effective and technically ideal solution, particularly when processing small parts in medium batches. This helps you get fine surfaces with neatly rounded workpiece edges, thanks also to the relatively long processing times. Trowal rotating barrels are also excellent for fine finishing and polishing. SOPHISTICATED TECHNOLOGY The barrel body is an octagonal, welded, biconal structure. It generates a triple sliding action in the mass of abrasive media with the workpieces to be processed. The lining consists of tear-proof rubber or PU, with the tight-sealing safety cover made of polyurethane. BARREL BODY WITH LIFTING AND LOWERING DEVICE The automatic lifting and lowering device lets you quickly feed and empty the barrel body. This is a major advantage, especially when processing times are short and when you are operating multiple rotating barrels.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results. APPLICATIONS: Orthopedic implants (medical engineering) Turbine blades (for airplanes as well stationary turbines) Precision components, for example, for pumps and compressors Work pieces made from tungsten carbide and other hard metals Fan wheels for turbo chargers (automotive industry) Sintered components, etc.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

INDIVIDUAL SOLUTIONSIf you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required. ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units. THE BENEFITS AT A GLANCE Individual mass finishing solution Modular system Choose from electromechanical or hydraulic system Partial automation possible

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

TT...SM CENTRIFUGAL DISC FINISHING UNITCOMPACT AND PIVOTING Centrifugal disc finishing units from the TT...SM range have an attached screening machine and integrated hopper for abrasive media. After processing the workpieces, the entire unit pivots by 135° to separate the abrasive media and workpiece mass on the screening machine. SUITABLE FOR HIGH-VALUE WORKPIECES While the system pivots back into the working position, the abrasive media are conveyed back into the work bowl. This centrifugal disc finishing unit is particularly well suited to processing high-value workpieces, making it a popular choice in the aerospace industry for example. THE BENEFITS AT A GLANCE Compact design saves space Cost effective Suitable for processing limited quantities

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

CONTINUOUS TROWALIZING OF NON-SENSITIVE PARTS The AV range of continuous units allows you to continuously process large quantities, with no need to interrupt the mass finishing process to add new workpieces. Thanks to the trough-shaped work bowl, you can process small and medium non-sensitive mass-produced parts (punched parts, die-cast parts, etc.), as well as larger parts (oil tanks, cylinder head covers, etc.). THE BENEFITS AT A GLANCE Continuous workpiece processing Interruption-free workpiece loading Trough-shaped work bowl Easy to integrate in fully automated mass finishing processes Simple material handling without batch loading

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

THE EFFICIENT SOLUTION FOR SMALL PRODUCTION SERIESAre you looking for a solution that is a more economical choice than a larger Trowal system? Then look no further than our E5 mini barrel. It is perfect for deburring and abrasion, above all on small workpieces from the optical and fine mechanics industries. The double-conically shaped rotating barrel body generates an intense rotation to achieve the perfect abrasion result. SOPHISTICATED TECHNOLOGY The mini barrel stands on a steel sheet construction with four pedestals. The barrel bodies are secured to a drive roller and support roller with locking rings. The barrel body is made from polyurethane and the quick-action cap is waterproof. SPECIAL EQUIPMENT It is also possible to attach two additional barrel bodies if necessary. These are driven via a roller system that is fully variable thanks to a three-phase motor. The cover can also be ordered with safety switches.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

MAXIMUM PERFORMANCE! Compared to vibratory finishing vibrators, Trowal Turbotron centrifugal units offer up to 10 times the grinding power. grinding performance. Turbotron machines are mainly used for the removal of heavy burrs and for edge rounding edges on small and medium-sized mass-produced parts. However, by applying special process techniques, Turbotron machines can also be used for fine grinding and even polishing. even polishing. HOW IT WORKS The rotation of the turntable (60-250 rpm) accelerates the abrasive / workpiece mass and the centrifugal force on the inner wall of the stationary work bowl deflects it upwards. deflected. Due to the onset of gravity, the mass slides back onto the turntable, from where it is accelerated again from there.

Request for a quote

SCHAKE GMBH

Germany

For civil engineering use, for bracing and supporting canal walls, acc. to DIN 4124 with test label TBG-4P 32. To combine the spindle with tubes of different length, the ring can be opened by special tool.

Request for a quote

WESTMARK GMBH

Germany

• enables easy and secure foil cutting • spring loaded • the tong-like shape offers flexible adjustment to different size bottle necks

Request for a quote

WESTMARK GMBH

Germany

• in square-edged, strong design • crafted from zinc diecast material • satin finish

Request for a quote

WESTMARK GMBH

Germany

• very solid version • original Monopol cutting thread • for plastic and natural cork • with cork & cap remover

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTMARK GMBH

Germany

• with the original Monopol cutting thread • suitable for plastic and natural cork • with cork remover • excellently finished mechanism

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We offer PU sheets in the dimensions 3000 x 1000 mm and thicknesses from 1 to 50 mm. Of course, special dimensions are also possible. PU round bars are available in the dimensions 70 °, 80 ° or 90 ° Shore A, dimensions 8 200mm x 1000m. Intermediate sizes can also be requested here. In addition to the extensive range of semi finished products such as plates, round rods, hollow rods and spring elements, molded parts with and without metal are also included in the scope of delivery. Mechanical rework such as water jetting, milling, drilling, sawing, punching and welding offers flexible potential from individual parts to series production. Possible Shore hardnesses from 55 ° 95 ° Shore A.

Request for a quote

WESTMARK GMBH

Germany

• two hardened steel prongs embrace the cork,without damaging it • ideal for brittle corks • with decorative casing from nickel-plated brass • with cap opener

Request for a quote

CARL RÖNTGEN GMBH

Germany

Our narrow bandsaw blades are produced in coils and ready for use. Here, we use the most common tooth form in the wood industry NV. We sell the narrow bandsaw blades as: toothed, toothed and set, toothed, set and sharpened. We offer the following pitches: 6 mm, 7 mm, 8 mm, 9 mm, 10 mm, 12 mm Below you can find the standard and semi-standard production program. (We can also produce other sizes. In this case, please contact us directly.) Standard (mm) Semistandard (mm) 10 x 0,6 10 x 0,4 | 10 x 0,5 10 x 0,6 12 x 0,4 | 12 x 0,5 15 x 0,6 15 x 0,4 | 15 x 0,5 | 15 x 0,7 20 x 0,7 20 x 0,4 | 20 x 0,5 | 20 x 0,6 25 x 0,7 25 x 0,4 | 25 x 0,5 | 25 x 0,6 | 25 x 0,8 30 x 0,7 30 x 0,6 | 30 x 0,8 35 x 0,8 – 40 x 0,8 –

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

With our own plant at Hagen we finish the basic material for our clients. Electrolytically galvanized in matt or glossy finish and, if required, subsequently phosphated and/or chemically passivated. In addition we can chemically phosphate in accordance with the bonding process. The technological properties of the carrying strip are completely retained during this process. Hence the primary material and the surface finishing produce a high-quality material, which you can easily process and use for many purposes. Details of the properties: - High corrosion-resistance - Best painting capabilities - Decorative appearance - Uniform, homogenous layer thicknesses (1-15 my / side) - Low reject rates - No longer high unit finishing costs - Avoidance of environmental problems - Good deep-drawing behaviour

Results for

Finishes - Import exportNumber of results

23 ProductsCompany type