- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- explosion-proof motors

Results for

Explosion-proof motors - Import export

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

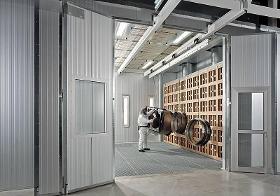

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

FRIEDRICH SCHULTZE GMBH

Germany

Explosion-proof heaters - ATEX – Standard. Explosion-proof heaters are used in many industrial or commercial applications that are classified as hazardous areas. Our appliances are used to heat the ambient air of hazardous areas in zone 1 and 2, typically in chemical industries, paint and lacquer industries, sewage plants and mining. Heaters made of high-grade stainless steel are recommended for aggressive environments (e.g. sewage plants), while heaters with a painted or coated surface, also available with protection basket, are sufficient for standard applications. Available on request: further types of explosion-proof heaters and our technical data sheets, as well as the TR-CU certificate.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® EXPLOSIONPROOF SPACE HEATERS CSN® explosionproof space heaters are used for heating zone 1 and 2 hazardous areas. Standard devices are available in the common temperature classes T1 to T4; temperature classes T5 and T6 can be offered on request. The use of finned tubes for the CSN® explosionproof space heaters is the most economical solution for heat transfer in the field of electric heaters. By coiling corrugated helical fins on tubes of different alloys, we obtain extremely large tubes surfaces and, consequently, low temperatures on their surfaces. We use this interaction to produce explosionproof space heaters on a highquality level. CSN® explosionproof space heaters with coiled fins are intended for horizontal mounting and suitable for both wall and floor mounting (for permanent installation)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Explosion-proof motors - Import exportNumber of results

4 ProductsCompany type