- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electricity solutions

Results for

Electricity solutions - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The double anodization process can be used to create a protective anodization layer on various parts of a consumer electronic product, including top and bottom portions, side walls, and chamfered portions. It’s particularly useful for improving corrosion resistance and wear resistance, and it provides better adhesion for paint primers and glues than bare metal does. The process is not limited to aluminum; it can also be applied to other metals like titanium, zinc, magnesium, and others. However, aluminum is the most common due to its widespread use in consumer electronics and other applications where weight and durability are important factors.Double anodization is a complex process that requires precise control over the electrolytic solutions, electrical current, and time to ensure the desired outcome. It’s a testament to the advancements in materials engineering and its ability to tailor the properties of metals for specific applications.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

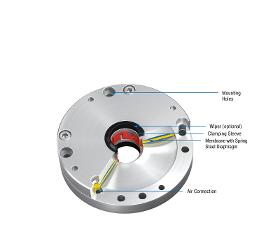

Pneumatic Rod Clamping, Compact Holding force 700 N Holding torque 7 Nm Compact and safe: when space becomes restricted, the compact LOCKED PRK clamping elements come into their own. As pneumatic rod clamping with low heights of 28 to 34 mm, they provide clamping forces of up to 5,000 N. Clamping is carried out by a diaphragm spring-plate system and is released when compressed air is applied. Clamping elements from the LOCKED PRK product family absorb the forces on rods with diameters between 20 and 40 mm both axially and rotationally. The function makes them suitable for use as static clamping without pressure, because the failure or drop of pneumatic pressure triggers immediate clamping. High clamping forces with low system costs compared with hydraulic and electric solutions make these clamping elements particularly interesting.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

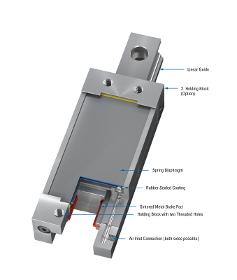

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

TROTEC GMBH

Germany

ELECTRIC HEATER FAN TDS 19 EFiery red mobile heater as a convenient all-round solution The red electric heater fan does not only have a fiery look, but also presents the ideal heating solution for construction trailers, indoor market stalls or smaller workshops. For the TDS 19 E can be employed at basically all locations where the use of oil and gas heating devices is undesirable or even prohibited, such as in unheated rooms. Thanks to the integrated power cable, all it takes to operate the mobile heater is a socket. The warm air flow generated by the TDS 19 E can be infinitely adjusted to the exact desired temperature, and its heat output can be regulated as needed using the two-stage power control. Beyond that, fan operation without heating function is also possible.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Electricity solutions - Import exportNumber of results

6 ProductsCompany type