- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical material

Results for

Electrical material - Import export

IGUS® GMBH

Germany

Solutions for plates Application examples - Automotive The new solution for all applications in stamped sheet metal retainers: iglidur® Clip On's are frequently used in seat and convertible top systems and multi-joint hinges. iglidur® clip-on bearings facilitate captive assembly even in punched sheetmetal / steering arms with limited fine blanking content. Compensation of axial clearance Loss secure pre-assembly possible Electrically conductive materials are optionally available Pressure-resistant materials until 80 MPa The Clip On bearings can also be produced from electrically conducting iglidur® RN89, thus permitting e-coating.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

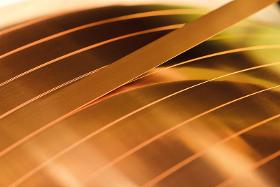

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical components, installation parts in the electrical industry. Zinc content proportionally reduces metall costs.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN ® Explosion proof cartridge heaters as direct heaters for liquids or gases in hazardous environment. These units are equipped with a heating bundle or a replaceable ceramic heating element. For temperature control these heaters are available with an integrated temperature monitoring system. These devices are available in various material grades. The electric cartridge heating element type 93./..EEx….T.(.) is designed for the heating of liquids in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 2014/68/EU) Art. 4, Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL Further information about our CSN® ExCartridge Heater

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

System for the impregnation of electomagnetic coils, e.g. of electric motors, transformers, generators Impregnating in electricla engineering means applying an impregnating agent in gaseous or fluid form to a porous body in order to insulate it electrically, i.e. that reliable protection against electrical breakdown is provided even when the thickness of the insulating layer is small. For each application HÜBERS provides appropriate process. HÜBERS offers all relevant process variants including vacuum impregnation, vacuum-pressure impregnation and atmospheric impregnation and of these coupled with the use of the many different impregnating agents such as varnish, resin, oil, wax, gas etc. The processes of evacuating the parts prior to impregnation and if necessary of vacuum-drying the impregnated parts are matched to the properties of the parts and ensure that the agent wets the walls of the pores properly and fills the cavities completely.

Request for a quoteResults for

Electrical material - Import exportNumber of results

16 ProductsCompany type