- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drives controls

Results for

Drives controls - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Cost-efficient transport between floors The vehicle lift CARRICO is an interesting alternative to the TRAFFICO when lower lifting heights and less frequent use are needed. The CARRICO has been type-tested in accordance with the EU Machinery Directive 2006/42/EC. The conveying speed is limited to 0.15 m/s. Furthermore, this car lift is delivered with automatic sliding doors and cabin equipment designed for the transport of vehicles and passengers. Functions of the components Door type: automatic sliding door (depending on the cabin width - 4- or 6-leaf) Entrances: front only / through Control: Control unit with micro-processor with extensive control functions Drive: Submersible hydraulic unit incl. screw spindle pump Advantages Saves on construction space as no ramp required Especially suitable for narrow shafts Cost-effective way to transport cars Easy to operate, manual hinged doors

Request for a quote

IGUS® GMBH

Germany

Drive units with 3 DOF with angle sensors Drive units with 4 DOF with angle sensors Drive units with 5 DOF with angle sensors robolink® drive units for all articulated arms Significantly expanded workroom Freely configurable arm length through modular design Step motor driven Alternative drive/control systems easily possible Drive units with 3 DOF with angle sensors Drive units with 4 DOF with angle sensors Drive units with 5 DOF with angle sensors

Request for a quote

IGUS® GMBH

Germany

Drive unit 3 DOF Drive unit 4 DOF Drive unit 5 DOF robolink® drive units for all articulated arms Significantly expanded workroom Freely configurable arm length through modular design Step motor driven Alternative drive/control systems easily possible Drive unit 3 DOF Drive unit 4 DOF Drive unit 5 DOF

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

The Multilift is for continuous height adjustment of tables, equipment, assembly workstations and similar applications. The lifting column can be operated alone or as a pair in parallel. To establish a configuration with absolute synchronous run of several drives (maximal 4) a special drive control is available as synchronous version. Max. travel. 498 mm Max. compressive force. 3000 N Max. tensile force. 1000 N Max. travel speed 8 / 16 mm/s Protection rating IP 20

Request for a quote

GSW SCHWABE AG

Germany

Motorized rotation Hydraulic wedge type expansion Highend arbor with double bearing Extremely stiff design SHDH Series PullOff Reel with manually adjustable brakes SHDR Series Payoff Reel with threephase motor Pneumatic or hydraulic hold down arms Electromotive or hydraulic traveling feature w optional automatic centering Hydraulic coil car and fullsize back plates Conical keeper rolls w optional motorized travel Larger mandrel heights and segments Vectorcontrolled drive systems for heavy coil weights Servo drive and control systems, etc.

Request for a quote

SONDERMANN PUMPEN + FILTER GMBH & CO. KG

Germany

Universal drive control for utmost efficiency MAGSON magnetically coupled centrifugal pumps are extremely efficient by nature. Using the SFU frequency converter for optimum adjustment to changing conditions, this efficiency will increase even more. Thanks to leading-edge control technology, the SFU permanently adjusts the discharge rate to specific requirements. Whenever the rate has to be reduced or the pump has to be operated with changing volume flows, using a frequency converter will save you lots of money. Thus, the power required by a pump running at half speed is only 12% of the original demand. So the system operates with optimum efficiency but saves a lot of energy, especially in part-load operation.

Request for a quote

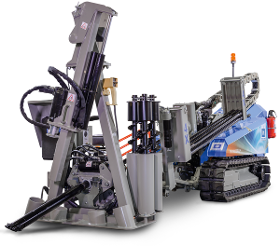

TRACTO-TECHNIK GMBH & CO. KG

Germany

Kubota diesel engine with 28 kW driving power Control station with easy to survey control panel Multifunctional joystick Hydraulic anchor bore unit swivels in three positions Remote control Drill rod magazine with 32 drill rods for 48 m bores Stabiliser blade, rubberised steel track undercarriage

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Most durable hydraulic wedge type expansion, easily operable even under weight Highestquality reel arbor with doubled maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability SHH Series PullOff Reel with manually adjustable brake and auxiliary drive to support coil setup SHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Electromotive or hydraulic traveling feature Hydraulic coil car Concical keeper rolls w optional motorized travel Larger mandrel segments Different mandrel heights Fullsize back plate Vectorcontrolled drive system for heavy coil weights Servo drive and control system Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

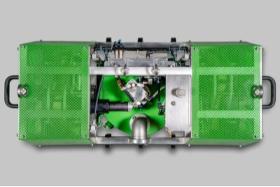

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Congrav® CB-S installed in control box or cabinet — Supply voltage: 24VDC — control software for discontinuous dosing of gravimetric dosing devices — Operation on the Brabender fieldbus and master computer — Serial drive controller — Serial load cell — Digital signals — Integrated bus connector Operation: — Congrav® OP16-E — Congrav® OP6-E

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Congrav® CB-E installed in control box or cabinet — Supply voltage: 24VDC — control software for discontinuous dosing of gravimetric dosing devices — Operation on the Brabender fieldbus and master computer — Serial drive controller — Serial load cell — Digital signals — Integrated bus connector Operation: — Congrav® OP16-E — Congrav® OP6-E — Congrav® OP1-S

Request for a quote

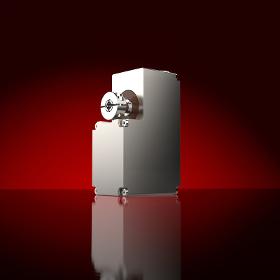

TEST GMBH

Germany

Torsion testing machines by TesT are executed as horizontal machines with torsionally rigid machine bed. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

For measuring ranges up to 600 Nm Torsion testing machines by TesT are also available as vertical machines, equipped with T-slot table and height-adjustable drive. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

The TesTController 850 is able to process up to six measuring channels with a 24 bit resolution and further six channels with a 10 bit resolution. In addition, it can handle three measuring channels for incremental signals. For controlling of drives there are three regulations channels available, so that even complex combination drives are possible (e.g. force and torque control at the same time). The maximum control frequency is 1 kHz, the maximum measurement frequency is 50 kHz. This testing machine controller 850 may recognize sensors that are equipped with TEDS chips (Transducer Electronic Data Sheet acc.to IEEE 1451.4), read their properties and calibration data, and automatically calibrate them. Thus, these electronic units operate with dozens of different sensors, so that a complex recalibration is not required. All universal testing machines of the model series 106 - 114 are equipped with the TesTController 850.

Request for a quote

FRIWO GERÄTEBAU GMBH

Germany

•Supply voltage: 14V - 65V •Phase current: 300A •Motor types: PMSM •Control algorithm: Field oriented control with flux weakening •Functions: Automatic teach-in, four ride modes, reverse gear, boost, display control, smartphone app •Position feedback: Hall sensor •Analog inputs: 2 •Digital inputs: 2 •Communication: CAN, Smartphone Connectivity •Diagnostic interface: USB, CAN •Diameter: 155mm •Height: 45 mm •Weight: 970 g

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Control cabinets form the technical "central nervous system" of every production plant. They supply machine and plant components with electrical energy, protect electrical circuits, control drives and network machines with the Internet. In addition, they act as an interface for all information on the current plant and processing status and link production exactly where processes need to be accelerated and efficiency increased. Our subsidiary ATR Industrie Elektronik GmbH is your competent partner for the construction of switchgear and switch cabinets. We supply a wide range of different versions based on all current national and international standards. Switchgear is used in almost all industries, in addition to the wood-based panel and metal industry, e.g. in the automotive sector, in turbine and compressor technology, in energy supply or also in cooling and air-conditioning technology.

Request for a quote

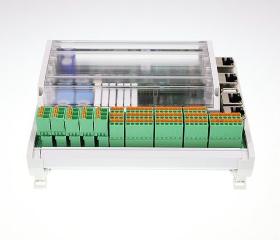

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive suitable for a wide range of applications in various industrial areas • Batteryfree multiturn absolute encoder • High dynamics • Optional use with the SeGMoBox or as a standalone device • Optionally with cULus component recognition

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive for installation situations with little space • Monitoring of important system parameters ensures reliable operation (overload protection) • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree due to sealedforlife lubrication • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

The fully ULcertified positioning system from Lenord+Bauer consists of three individual elements that can be flexibly combined as required positioning drives by the name of SeGMo, the decentralised SeGMoBox control unit for flexible fieldbus integration and the associated hybrid cable solution, including connectors, that is suitable for use with drag chains. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. Lenord+Bauer also offers these for standalone use. With nominal torques of up to 15 Nm, they cover the capacity range typical for secondary axes. Integrate the drives directly into your control system with the function blocks. Alternatively, you can automate up to 17 secondary axes using the decentral SeGMoBox. The box handles the power management for the connected drives and concentrates the interaction with the system control.

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Durable with high operational reliability. Powerful. Design features: • robust construction • automatic product feeding • Vacuum box extraction • Product-dependent carton suction • Carton erection in the chain • All-round product inserters • Main shaft drive • Frequency controlled three-phase drive • encapsulated gearbox • automatic chain tensioner • all product-carrying components made of stainless steel • Fast format adjustment • Gas pressure spring-loaded protective doors made from Makrolon • PLC control Additional devices: • Hot glue seal • Combined hot glue and plug closure • Special plug lock • Cardboard storage tapes with automatic magazine loading • Embossed printer for signing a flap • Coding (inkjet / laser), blind embossing • Code reader with or without folding box ejection device • Equalization for powdery or granulated products • Upper runner to support the insert easily deformable products • Inserts for brochures booklets, spoons etc.

Request for a quoteResults for

Drives controls - Import exportNumber of results

23 ProductsCompany type

Category

- Driveshafts and micro-motors - electric (4)

- Crate packing machinery (3)

- Metal straightening machines (2)

- Weighing and dosing equipment (2)

- Electrical & Electronic Components (1)

- Construction - Machines & Equipment (1)

- Cabinetmaking - machinery and equipment (1)

- High-pressure cleaning machines (1)

- Industrial sprayers for surface treatment (1)

- Pumps (1)