- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive shafts

Results for

Drive shafts - Import export

IGUS® GMBH

Germany

robolink® drive wheel Connection to motors Drive shaft d4 - d12 with/without feather keyway Material: PA2200 and aluminum 3.5 rope coils = 500 mm Rope way d1 [mm]: robolink® multi-axis joint robolink® Configurator d1 [mm]:

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Highly torsionally flexible coupling ARCUSAFLEX-VSK for drive shafts * Linear torsional deflection characteristic * Elements available in different torsional stiffnesses * Enhanced damping capacity through frictional damping * Maintenance-free coupling bearings * Radial bearing close to the cardan joint * A variety of designs for different cardan shaft configurations * Many types with SAE connection dimensions or as specified * Compact construction, the highly flexible element being protected by the housing * Fail-safe device visible from the outside for ease of inspection

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

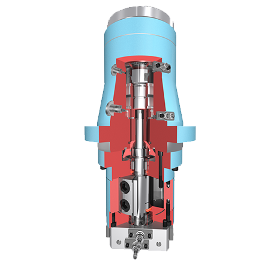

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

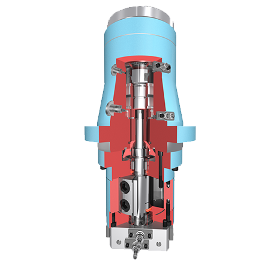

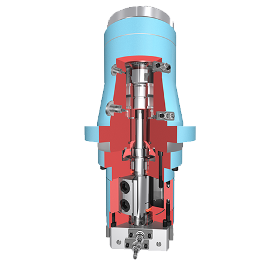

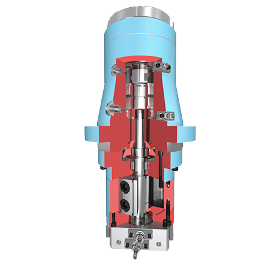

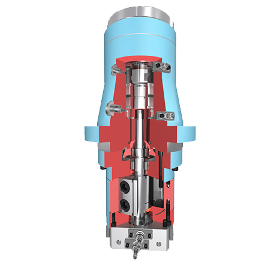

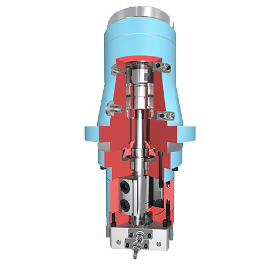

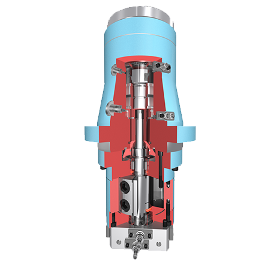

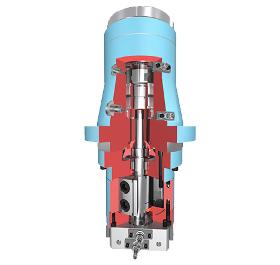

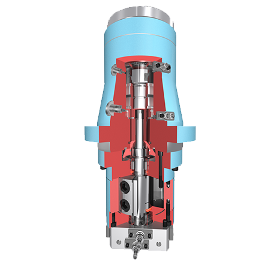

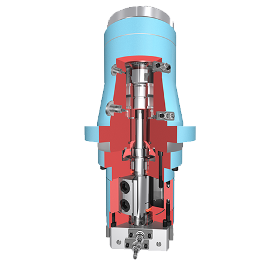

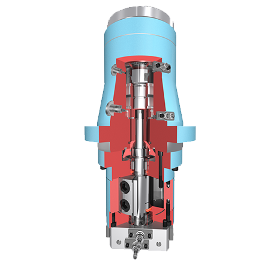

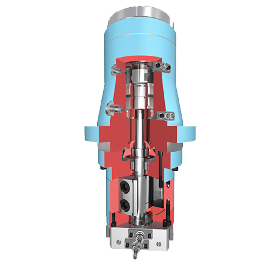

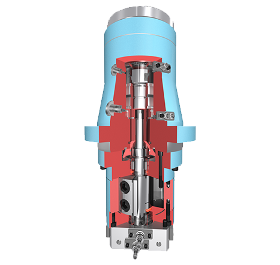

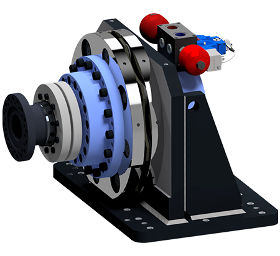

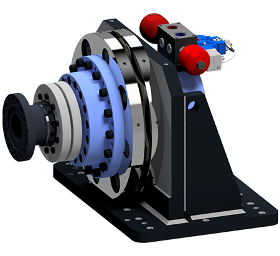

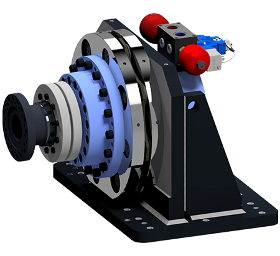

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

RUHRGETRIEBE KG

Germany

Two-stage gear drive with solid shaft Gear Type: SN12 Motor Type: Three-Phase, Direct Current and Permanent Magnet DC Mounting: Gear Foot Ausgangswelle: Solid Shaft Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

Two-stage gear drive with solid shaft Gear Type: SN4F Motor Type: Three-Phase, Direct Current and Permanent Magnet DC Mounting: Flange Ausgangswelle: Solid Shaft Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

Two-stage gear drive with solid shaft Gear Type: SN6 Motor Type: Three-Phase and Direct Current Mounting: Motor Foot Ausgangswelle: Solid Shaft Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quoteResults for

Drive shafts - Import exportNumber of results

126 ProductsCompany type