- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die cuts

Results for

Die cuts - Import export

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 685072 Laser-cut cutting Specification Laser-cut cutting Laser-cut cutting, woven elastic, flame-retardant finish Model type: C (Customised) Dimensions: approx. 110 x 40 mm Material: Polyester Colour: black Property: elastic Packaging: loose in cardboard box Note Features: Laser-cut cutting, with position and stitching markers, flame-retardant finish

Request for a quote

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 685633 Laser-cut cutting Specification Laser-cut cutting Laser-cut contoured cut Model type: C (Customised) Dimensions: approx. 550 x 210 mm Material: Polyester Colour: black Property: non-elastic Packaging: loose in cardboard box Note Features: Laser-cut contoured cutting

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 65 V revolving cross cut / rip cut saw Equipment / scope of supply- Cutting heights 90° / 245 mm - 45° / 164 mm - 30° / 113 mm - Machine table with lateral movement approx. 400 mm with pneumatic brake system - Machine hood with lateral PVC protective curtains - pneumatic clamping cylinder left - right - pneumatic cross-cutting operation using two-hand control - electrical saw blade inclination 90 – 30° - Revolving table 0 - 270° - Laser light for cross-cutting - Saw bla de height adjustment via mechanical stop system with scale - TCT saw blade 650 mm, dust extraction spigots 160 / 125 mm - Drive motor 12 kW – direct motor speed 1/min – 3,000 - Saw blade speed 1/min – 3,000

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

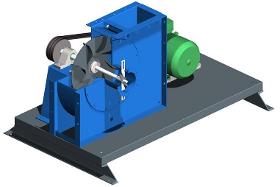

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 28 x 2 mm for stainless steel tubes Shortest separation length: — 25 mm (without pull apart) — 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Laser cutting parts and bending parts: Your special production in good hands. As part of the Schulz Group, Schulz Stanztechnik can also offer you – as a service and in addition to the stamping program – special laser cut parts in various materials and thicknesses. In accordance with your drawings, you will receive a meaningful offer from us within three working days, and your laser parts within ten working days of your order. Manufacture of 2D and 3D laser parts made of the most diverse of materials as well as angles in accordance with your drawings and specifications.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The secutex material may be sawn using a conventional band saw. The material will attempt to resist the cutting tool. Use as low a wedge angle as possible and, if necessary, adjust the cutting speed.

Request for a quote

GSW SCHWABE AG

Germany

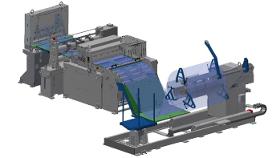

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

GSW SCHWABE AG

Germany

With 2,5 degree cutting angle for clean, burrfree edges With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

CARL SCHMIDT SOHN GMBH

Germany

Wood fiber cutting board LUBECK use various natural materials and pressed under extremely high pressure and heat, so the cutting board is exceptionally strong, but still retains the texture and natural appearance of the wood. It has a high-density surface and non-absorbent properties, which effectively prevents mildew and bacteria.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Robust and durable As a naturally renewable raw material, wood is not only one of our favourite building materials, it can also be disposed of and recycled with comparative ease. For old wood recycling, tables, kitchens, damaged railway sleepers or chipboard are recycled using singleshaft shredders. In these machines, our cutting crowns and knife holders in a very wide variety of sizes and versions have been used for many years and have proven themselves in practice day after day.

Request for a quote

GSW SCHWABE AG

Germany

Our sequence-controlled system includes a precision welding head and precise cutting and positioning devices. The two integrated Hydraulic Shears and the strip clamps can be moved so that the leading and trailing strip ends can be fitted precisely. For those who like it less automated but more cost-effective, we have developed a simpler technology – using just one Hydraulic Shear and fixed clamps. The strip ends are positioned manually here – this is supported by an easily accessible hand lever to individually activate the pneumatic clamps. A double edge guide with vertical rollers centers the new strip and can be adjusted also decentral for alignment. The actual welding process is taken over by the operator himself.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting flat cables without squeezing • Improved cutting geometry for simple cutting and higher operating times • Ratchet-shaped clamping of the cable ensures crimp-free cutting • Precision cutting edge for a smooth and clean cut without any burrs • Re-adjustable screw-joint • Handles with ergonomically shaped SoftGripp multi-component sleeves • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Ergonomic handle position and shape for optimum power transmission • Professional design for easy handling under permanent load • Made of special tool steel, forged, oil-hardened

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For the even chopping of continuous strips. Cutting fans Our cutting fans chop continuous strips, such as those found in the furniture industry, for example. 4 blades and counter blades located in the suction nozzle ensure even chopping. Subsequently, the material is fed via a pressure pipeline to the place of destination.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

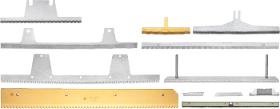

Your foil and processing requirements determine our knife design. Regardless of whether the foil should be impermeable or permeable, vacuumable or sealable, tearable or much more, they will be cut reliably with the best possible knife.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

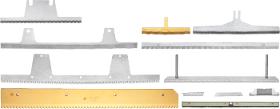

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Biofilms consist of a wide variety of raw materials or combinations of raw materials. They have very specific material properties. Knives need to be matched to these properties to produce cuts, serrated cuts, tabs, tear-off aids, etc. And all that with the reliability and speed that produces organic and economical joy.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Extremely durable materials place extreme demands on the knives with which they are processed. Our knives are customized for a wide variety of material mixtures and therefore perform excellently in cold and hot cutting processes.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

We develop precision-cut knives for a wide variety of foils. Irrespective of whether the foils are extra thin, unusually thick, viscous or elastic, or whether they are shrink-wrapped, printed, finished, environmentally friendly or else biofoils - we supply the best knives.

Request for a quoteResults for

Die cuts - Import exportNumber of results

49 ProductsCompany type

Category

- Components and parts for small household appliances (9)

- Knives, industrial (6)

- Cutlery, household (5)

- Metal straightening machines (4)

- Laser - cutting and welding machines (3)

- Sawing machine tools (3)

- Industrial equipment hire (3)

- Machine tools, cutting - parts and accessories (2)

- Gas and oil - exploitation (2)

- Steels and metals - forming and cutting (1)

- Shearing machine tools (1)

- Foundries - copper, bronze and brass (1)