- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- custom work

Results for

Custom work - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in mechanical shaft.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Special mechanical engineering - unique, individual, tailored For the plant, machine and special machine engineering sector, we manufacture ■ custom-made components ■ casings and coverings ■ machinery racks ■ noise-protection cabins ■ complete assemblies Thanks to our vertical integration combined with a large material storages, we are realizing shortest throughput time for your projects on highest quality level. We serve numerous sectors like the rubber industrie, steel processing industry, automation technology, consumer goods industry, energy industry and any other branches where individual steel, stainles steel and aluminium components and assemblies are needed. Whether you want custom-made components or ready mounted and suface-finished overall systems, we do it for you!

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

With state-of-the-art can sheet production lines and recycling centers in North America, South America, Europe and Asia, Novelis serves the most recognizable brands including Coca-Cola, Crown, Ball Corporation, Ardagh Group and ABInBev. Beverage cans are, and will remain, the core of Novelis’ product portfolio. Working alongside our customers, we innovate to meet the ever-evolving preferences of consumers, whether for new shapes and sizes, alternative coatings or more. For example, Novelis is working closely with customers to develop and produce distinctive aluminum bottles, which offer the same portability, light weight and recyclability as aluminum cans, but with the added benefit of being re-closeable. In addition, Novelis is also working on technology to support our customers seeking to meet consumer demand for sustainable packaging for new beverage categories.

Request for a quote

XIMEA GMBH

Germany

We design for performance! When it comes to custom engineering we work with you as a team in close collaboration. That is before, during, and after the job is done. If you aim to develop your project further we are always eager to assist you with a creative, rapid, and highly efficient OEM-design. Starting from scratch or using any existing XIMEA product as a seed, we provide services all the way up to full custom developments and manufacturing.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

cryogenic decoating of big-sized parts Take advantage from our experience! We offer customized solutions for: ■ decoating of big-sized parts (e.g. vulcanized metal housings, tools, etc) ■ devices for metal shringking-work The individuel customized solution will be performed according to customer specification!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

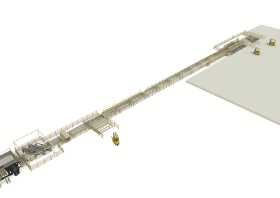

The cooling and stacking line, which is downstream of the ContiRoll®, is the rst part of the nishing line. This is where the continuous process becomes a discontinuous one and the boards are cut from the endless mat. The cooling and stacking line is the rst section of an intralogistical concept that Siempelkamp develops with the customer: We work with the plant owner to dene the best master-board formats that will allow the later end-product formats to be made without ocuts. We develop all downstream processes for the master board and product on the basis of optimum material ows in constant dialogue with the customer. To this end, Siempelkamp sets up a team of experts that will act as the reliable partner throughout the process – from the intralogistical concept, technical implementation, assembly and commissioning/start-up to ongoing support Features and functions Saw section Rejects area Cooling section High-stack forming

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The cooling and stacking line, which is downstream of the ContiRoll, is the rst part of the nishing line. This is where the continuous process becomes a discontinuous one and the boards are cut from the endless mat. The cooling and stacking line is the rst section of an intralogistical concept that Siempelkamp develops with the customer: We work with the plant owner to dene the best master-board formats that will allow the later end-product formats to be made without ocuts. We develop all downstream processes for the master board and product on the basis of optimum material ows in constant dialogue with the customer. To this end, Siempelkamp sets up a team of experts that will act as the reliable partner throughout the process – from the intralogistical concept, technical implementation, assembly and commissioning/start-up to ongoing support.

Request for a quote

LINER FACTORY GMBH & CO. KG

Germany

“I expect my adhesive to bond perfectly, just not to the outer packaging!” A customer request that is more than justified and one which we have taken to heart. We can thus now offer tailored linings for containers made from tin, plastic or any other material that optimally meet customer requirements. We are continuously working on ways in which to improve our products, with skilled and experienced employees happy to explore innovative liner solutions. Because the chemistry must be right, between the liner and the filling material, as well as the company and our customers. This is why we strive to always take an eco-friendly approach, focusing on an environmentally sound and thus separate disposal of packaging – from the order through to development and, ultimately, the satisfied customer: perfection from start to finish.

Request for a quoteResults for

Custom work - Import exportNumber of results

9 ProductsCompany type