- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning spray

Results for

Cleaning spray - Import export

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Complete set for cleaning computer monitors, plastic surfaces and keyboards. • Complete set for gentle cleaning of screens and plastic surfaces • Gentle foam cleaner for plastic surfaces • Pump stray for streak-free monitor cleaning • Contents: SUPERCLEAN FOAM 150 ml cleaning foam, SCREENCLEAN FLUID 125 ml cleaning spray , 10 lint-free fleece wipes, 3 keyboard cleaner

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Set consisting of pump spray and microfibre cloth for cleaning and maintaining whiteboards. • Whiteboard cleaning set • For cleaning and long-lasting care of whiteboard surfaces • Suitable for dry-erase whiteboard markers • Contents: 250 ml pump spray, high-quality microfibre cloth 25 x 25 cm

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Foam for cleaning and maintaining whiteboards. Anti-drip after spraying on. • Foam cleaner for whiteboards • No running after spraying on • Suitable for dry-erase whiteboard markers • Can be used, for example, with DRY CLEAN wipes product # 5734 • Contents: 400 ml

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Pump stray for streak-free monitor cleaning. • Cleaning spray for screens on computers, laptops, tablets, smartphones and navigation devices • Also suitable for cleaning glass surfaces, e.g. on copiers and scanners • Can be used with DRY CLEAN wipes product # 5734 • Contents: 250 ml

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Pump stray for streak-free monitor cleaning. Including a microfibre cloth integrated into the lid to save space. • Cleaning spray for screens on computers, laptops, tablets, smartphones and navigation devices • Also suitable for cleaning glass surfaces, e.g. on copiers and scanners • Including a microfibre cloth integrated in the lid to save space • Ideal for removing fingerprints, dust and dirt • Contents: 200 ml

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

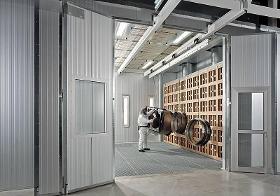

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Individuality and problem-solving are our strengths The PERKUTE system offers solution for every requirement in industrial cleaning technology. Many special solutions could be developed because of the wide product range. We have compiled some reference examples of already implemented special solutions. Special Solutions/ application examples Conveyor machine TW 103 with handling equipment "For cleaning closing thrustor in time of the machine center" Conveyor machine TW 108 with return transport passage "Cleaning of synthetic material boxes" Dip facility TL - 70T "Cleaning of valve cases" Conveyor machine TW 101 with feed system and delivery "Cleaning of hollows" Spraying cleaning facility FR-130H "Cleaning of goods carrier" Spraying cleaning facility FR-90H "Cleaning of store cages in bulk baskets" Spraying cleaning facility RC 82 "Cleaning of drawing dies with with 100 bar"

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Removal of adhesive residues on grinding instruments with the Spray cleaning device Clean-o-mat RC 82 Parts cleaning machine for removal of adhesive residues on grinding instruments with approx. 100 bar pressure. The nozzle tube system and the clamping device are adaptable to the grinding wheel diameter.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Special solution: Parts cleaning machine Clean-o-mat SP 80 with additional hand-spraying device Toploader Clean-o-mat SP 80 with additional hand-spraying device (160 bar/optional), inspection window and lighting for the manual cleaning of complex parts.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

A solid single-chamber parts cleaner for automatic water based spray cleaning. This series is extendable by varies extras which can be retrofitted. The RC-machine is a low costs entry to the modern world of industrial parts cleaning. The PERKUTE-system: economically - environmental – effektive Basic equipment Compact and sturdy construction Made of stainless steel Simple operation Space-saving 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Suction filter made of stainless steel front of the pump Adapter for steam extraction Basket drive by water pressure (RC 68, RC 82) Electronic basket drive (RC 122, RC 162) Preparation for electronic basket drive (RC 82) 2“ socket slide vlave for the tank emptying Safety limit switch at cover

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Toploader Series The PERKUTE rotating basket cleaning machine from the Toploader series is used wherever effective and inexpensive cleaning of parts of any kind is necessary. The rotating basket, designed for large weights, is powered by means of a low-wear friction wheel drive and the aqueous cleaning in the spray process takes place by means of a nozzle pipe system with special flat-spray nozzles that is arranged on 3 sides. A powerful washing pump supplies the system with the necessary pressure and volume flow. The parts cleaning machines, made completely of non-rusting special steel, istinguish themselves by their compact and robust construction as well as simple handling. They are mobile to deploy and designed to be space-saving. Customisation for individual cleaning tasks can be optimised through a comprehensive range of accessories.

Request for a quoteResults for

Cleaning spray - Import exportNumber of results

13 ProductsCompany type

Category