- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt tensioners

Results for

Belt tensioners - Import export

AMSBECK MASCHINENTECHNIK GMBH

Germany

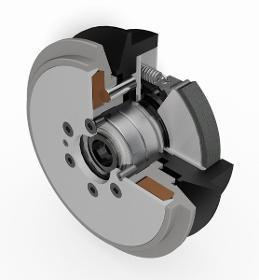

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

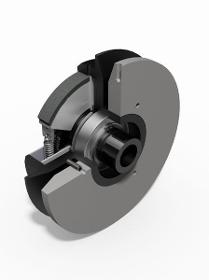

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

BAUER GMBH

Germany

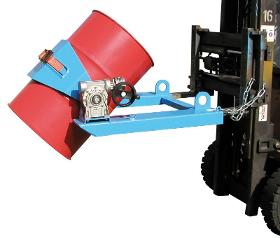

-sturdy frame with fork sleeves -prism pick-up with tension belt and -double worm gear -can be secured to prevent slipping -load capacity 300 kg -range of rotation 360° -suitable for pick-up by a forklift truck, dumper or crane Types available -Type FLEX-HK tipping process by crank handle -Type FLEX-K tipping process by loop chain

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

IBK WIESEHAHN GMBH

Germany

Fabric compensators are highly flexible and usually made of multi-ply fabric, offering excellent temperature resistance and chemical resistance depending on the particular design. Mainly used in pipe and conduit systems to compensate for axial, lateral and angular movements. One major advantage of this type of compensator is the low restoring forces. Special fabric materials permit temperatures of up to 1,000°C. Additional insulation can be used to resist temperatures of up to 1,600°C . Applications: Chemical plants, refineries, metallurgical industry, ventilation systems, chimney construction, industrial furnace construction, power stations, boiler systems, waste incineration plants, acoustic decoupling. Materials: Kevlar, fibre glass, glass needle felt, stone mineral wool mats, ceramic fabric, ceramic fibre mats, silicate felt mats, silicate fabric, Teflon Connection types: Continuous screws and screwed counter flange, clamping bars, tensioning belts straps

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is of vital importance that the oriented mat be conveyed precisely from the forming line into the infeed head of the ContiRoll®. Otherwise a dependable production process and a symmetrical heating of both surfaces could not be guaranteed. We therefore use an intermediate belt, which is perfectly tuned to the exible infeed head of Siempelkamp’s ContiRoll® and which adjusts automatically to the respective recipe and process Parameters. Features Basic frame including belt drive Belt tracking unit Tensioning device Motorised slide table, swivelling and moving in production direction Pulley unit Advantages Preassembled unit, modular design integrated in the forming line Positioning of the slide table in the press infeed in dependence on the recipe Options Belt cleaning brush Seamless, endless belt

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Belt tensioners - Import exportNumber of results

6 ProductsCompany type