- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt rollers

Results for

Belt rollers - Import export

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Requirements for products working in a high temperature fusing environment include continuously increasing requests for longer part life, higher print speed, and better print resolution involving ongoing material and process innovations. Our goal is to find the best combination of the following properties: Thermal resistance Thermal conductivity Abrasion resistance Anti-adhesive surfaces Elastomer hardness Substitution of Metal Substrates by Polyimide Belts Fusing by heat and pressure in digital printers has previously been realized with anti-adhesive coatings on aluminum or steel cores. These metal substrates have been increasingly replaced by seamless thin walled polyimide belts due to energy-saving environmental regulations and the growing requirement for “instant on” printing devices. Image Fusing Products Fuser rollers with soft and thin coatings more Fuser rollers for professional digital printing more Pressure rollers with solid silicone/PFA sleeves more Pressure rolle

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The secondary heating system is an integral part of the ContiRoll® and one of the decisive factors for its optimal functioning. For a perfectly dimensioned secondary heating system signicantly contributes to its eciency. The oil is heated in the boiler house to the temperature required and delivered to the primary circuit. The secondary heating station maintains the temperature in the secondary circuit to the press at set temperature by mixing the oil returning from the press that has already cooled down with the hotter oil of the primary circuit. The thermal oil transfers its thermal energy via hot platens, roller rods, steel belts to the mat to be pressed. Features Advancing temperature of the primary circuit is 280 °C Quick-acting aps for immediate re protection Heating circuits for setting the temperature distribution required by the respective process over the entire press length

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

When resins containing isocyanate (MDI, PMDI) are used, particles and bres are prone to stick and cake to the steel belts in MDF, OSB and particleboard production. These processes require the use of release agents to be sprayed onto the steel belts. In the press infeed drum seat of the ContiRoll® one unit each is installed at the upper and the lower infeed drums. The release agent application device uses a dip roller to spread the release agent onto the press belts. The surface-textured dip roller rotates inside the release agent tub. The dip roller is pressed against the application roller (setting force is adjustable) to transfer the release agent. The applicator roll applies the agent to the steel belt. Features Precise and economical setting of the agent between 7 and 18 g/m²depending on the product.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

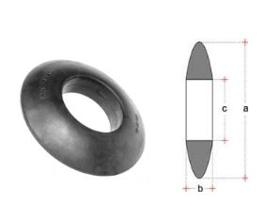

Support rings for type A carrying rollers Type A support rings prevent sap build up and the build up of dirt on the carrying rollers and ensure a straight run in the bottom strand. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance. In addition to the proven standard, we also manufacture special quality rings such as white food quality rings, oil and grease resistant rings, and rings for extreme temperature ranges ( 40° C to 180° C). Support rings for type B carrying rollers Rollers fitted with type B support rings are used as bottom belt rollers. They are generally placed on the ends of the carrying rollers. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has enjoyed renown for belt conveyor hooded covers made of metal for many years. We have decisively extended our product range with the sale and distribution of plastic cover hoods. Due to statutory requirements, different sectors of industry require alternatives to the metal systems. In particular, the industries of food, sugar, chemicals, potash and salt are reliant on hooded covers made of Organit plastic. The corrosion resistant hoods reliably protect conveyor belt, roller bearings and the material conveyed against the weather. They can be easily removed at any location so that the conveyor belt can be inspected and then replaced. Organit conveyor belt hooded covers made of rigid PVC, transparent and natural, in sheeting pile 70/18 have the following features hardly inflammable DIN standard 4102 impact resistant DIN standard 7748 chemically stable DIN standard 16929 maintenance free low weight easy handling

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Spiral rings are mounted on standard rollers and used to clean conveyor belts. When the idler roller rotates, the spiral rings move the dirt from the center of the belt outwards through a tumbling motion. The spiral rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently fixed on the conveyor roller and are characterized by their abrasion resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

Beam machine for irradiating a glass sheet conveyor belt Transport device supporting roller guide, motor nozzle movement, infinitely variable, attached dust filter system and electronic Control. Max. Lens height for automatically rays 1.200 mm Max. Lens height for manually rays 1.500 mm

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quoteResults for

Belt rollers - Import exportNumber of results

12 ProductsCompany type