- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt conveyor

Results for

Belt conveyor - Import export

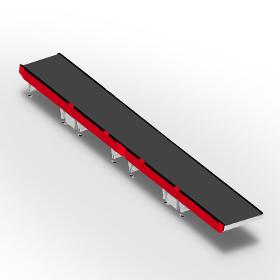

GSW SCHWABE AG

Germany

the conveyor system TB2000 distinguishes itself through its compact design. A modular scaling allows quick delivery while serving a great variety of applications. large belt widths and higher capacities allow removal of scrap also with bigger presses. the nuts on the sides can be used problemfree for tightening the directional controls or other accessories

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Scope of delivery: 1x ball unit table 6x freely positionalable stop bar – long 4x freely positionalable stop bar – short 1x set of bolts anti-tilting Load capacity for tools, dies, injection moulding tools, assembly goods etc. up to: 500 kg – higher loads possible with ball units 022.100 Purposes Setup and dismantling, internal transport, flexible work table e.g. in toolmaking, can be used for forklift trucks, pallet trucks or pallet jacks Advantages Reduced set-up time, safe, flexible, universally applicable, simple and fast handling Safety at work flexible fall protection for conveyed goods, simple and quick tilt protection, stop bars freely positionable in the grid The SUTTY has a CE mark – Quality, made by Schulz!

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK Förderband Technik Kilian GmbH quick cleaning scraper is a special device to remove the scraper, whether drum scraper or lower belt scraper, from the conveyor belt as quickly as possible and to clean adhering materials. Tools are no longer required. Can be used, for example, in the area of film and paper recycling. Can be carried out by untrained personnel in just a few steps and without tools.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The heat resistant wiper has been specially developed for hot goods and high ambient temperatures, as this wiper is absolutely heat resistant up to 270 degrees. Suitable for drying drums (e.g. in asphalt mixing plants and lime plants).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH T bar scrapers are made of highly wear resistant polyurethane and are ideal for demanding applications in bulk, recycling and treatment technology. When the T bar scraper becomes worn, it can be turned simply and easily and can be reused several times over. A cost effective alternative to cleaning the return belt of conveyor belts Can be used three times by simply turning the PU T bar scraper end to end PU T bar especially for PVC and other types of plastic belts

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Pull cords are used as actuators for operating pull rope emergency stop switches along conveyor belt systems. The pull cord and the accessories required for installation are functionally matched to the pull rope emergency stop switch, taking normative requirements into account. We therefore constantly carry out Pull cord, steel cable, 3mm or 5mm red PVC sheathed Various types of tension springs Anchor hook M10 Anchor hook M12 Anchor hook M8 Turnbuckle M6; 2 eyelets Turnbuckle M6; 1 hook / 1 eye Chain link 6 Eye bolt M12x60 * Eye bolt M12x200 * Eye bolt M12x60 * Clamp bracket, size. 3 5 Clamp egg shaped, size. 3 Clamp egg shaped, size. 5 Thimble Gr. 3 Thimble Gr. 5 Marking plate for rip cord Deflection pulley M10x60, pulley And much more

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Knocker rolls are used on the cleat belt in order to knock off adhering material. The Knocker roll is fitted in the inner belt near the drive pulley. Area of use cleat belts and badly damaged belts Knocker rolls are used when it is not possible to use conveyor cleaning brushes. They can also be used as combination together with a conveyor cleaning brush.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

reasonably priced alternative for the cleaning of belt conveyors in the lower belt can be used twice by simply turning the bar round end to end PU turning bar also specifically for PVC and other types of plastic belts

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The drum plastic scraper is for use on light to heavy conveyor belt systems. High quality PU segments for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU segments also specially suitable for reversing conveyors belt speeds up to 5 m/s especially for badly damaged belts and PVC belts well suited for use in narrow space conditions limiting damage to the belt longer life expectancy and therefore significant cost savings due to new type of segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure)

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The heated scraper from FTK Förderband Technik Kilian GmbH is equipped with a heater and thermal oil, which prevents the material from freezing on the scraper, both the lower belt and the drum scraper. The heated scraper is particularly suitable for the cold season and at high minus temperatures.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

Belt conveyor is one of the carrying or transporting mechanisms of a recycling or waste management installation. Depending on the complexity of the waste materials mixture, the looping belt requires robust and durable properties to resist impact, wear and leaking of oil and grease.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

the conveyor system TB1000 is suitable especially for the integration into complex machines (e.g. removal of scrap from punching machines) because of its compact design the aluminum extrusion framework resists twisting and at the same time features good load capacities under the running surface of the belt, a stainless steel plate is mounted to secure an enduring resistance to abrasion

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

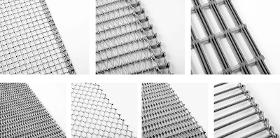

The Dutch Lesjöfors company Tribelt specializes in developing and manufacturing metal conveyor belts. For more than 70 years, the company has solved problems for customers in many different fields across Europe. We also manufacture sprockets, customized for the design and in the number your application require, its’ tension forces and surrounding environment.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

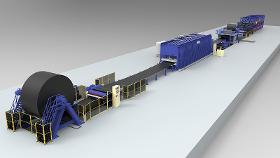

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a conveying speed of up to 3.0 m/s, flexibility and hardiness are also demanded of the curves. The area of application for the Motion06 Curved Belt Conveyor is in the continuous or clocked transportation of pieces of luggage and packages with changes in direction. When developing the Curved Belt Conveyor, the highest priority was given to the ‘small space requirements’ and a wide range of standard measurements or customerspecific measurements for integration into new or existing systems. The entire product range is a modular design and is designed based on stateoftheart technology. A consistent appearance for the operation of a wide variety of weight classes and product sizes is available worldwide. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage. UltraSimple Adjustments Ultrasimple adjustment to required installation conditions with modular system Universal Compatibility Can be combined with all conventional XRay machines. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

A real highperformance device – ingenious, innovative and extraordinary. Its job is to sort out pieces of baggage or general cargo from a conveyer line with the highest possible sorting output. Its capacity is up to 1,500 pieces of baggage per hour. The Motion06 High Speed Diverter is output to the power of two. The currently common and expensive twoband diverters can now be replaced economically. Thanks to the latest drive concepts (Class IE4), the High Speed Diverter is extremely energy efficient and the flexible construction concept makes changing the swivel direction on site simple. Maintenance free components with the lowest possible operating costs are included. Due to the standalone principle, the machine is easy to integrate without mechanical connection to the feed system (to the lower conveyor belt of the line).

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles. Simple Installation Ultrasimple adjustments for required installation conditions. Various Designs Horizontal or sloping design. Conveyor Casing Casing can be steelcoated or stainless steel. Low Maintenance Lowmaintenance friction drive Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 HighSpeed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157 Operational Safety High level of operational safety through the strip design. Smooth Transfer Closed belt surface for a smooth package transfer. Belt Tracking Integrated Automatic belt track fittings integrated. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low structural height. (approximately 250mm)

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles. Operational Safety High level of operational safety through the strip design. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low construction height available. (approx. 130 mm) Various Operations Various operations are available as well as cyclic. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

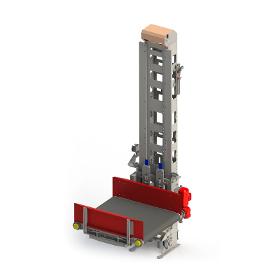

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Unique and light as a dragonfly – this is how the Motion06 Inclined Transport Unit works – quickly and safely overcoming any height difference. The inclined conveyor transports flight baggage directly to the passenger boarding bridge, meaning it can be used in direct proximity to the aircraft. Baggage or similar general cargo is either safely lifted onto the aircraft or lowered onto the apron. Staff must no longer carry the baggage up and down the sometimes wet or icy stairs in any weather. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation. Efficient Energyefficient and economic design. UltraSimple Adjustment Ultrasimple adjustment to required installation conditions.

Request for a quoteResults for

Belt conveyor - Import exportNumber of results

34 ProductsCompany type