- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearing supports

Results for

Bearing supports - Import export

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

Universal glide elements – customise your own plain bearing supported rotary table systems Using the versatile iglidur® PRT universal glide elements, large slewing ring systems can be modeled tailored to the type 01. Depending on the number of elements, rotary table systems can be implemented with inner diameters ranging from approx. 0.5 to 5m. – we will gladly support you with the design and detailed layout. Universal gliding element, made from the proven iglidur® J Customize your own slewing ring tables starting at 500 mm diameters and larger Lubricant free Maintenance-free wear-resistant Rugged Resistant to corrosion Typical applications:Solar industry, assembly equipment, fixture making 1. Glide element made of iglidur® J Part number: JRS-500S/45S Material table General features Density 1,49 g/cm 3 Colour yellow Max. moisture absorption at 23 °C and 50 %r.h. 0,3 Wt.-% Max. water absorption 1,3 Wt.-% Mechanical properties Max. permissible static surface pressure (+20 °C) 35 MPa Shore D hardness 74 Physical and thermal properties Max. long term application temperature 90°C Max. short term application temperature 120°C Lower application temperature –50° Electrical properties Surface resistance >10 12 Ω loads up tp 10 tons

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing and top cover as solid turned parts, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of three stamped parts, the casing, bearing shell, threaded pin, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of three stamped parts, the casing, bearing shell and top cover, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster consists of a casing with threaded pin and a top cover as solid turned part, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

GSW SCHWABE AG

Germany

Instead of mounting one or more Transporters to each die, the PSKS features one unit only – mounted directly to the face of the bolster. A heightadjustable mounting bracket allows flexible usage with multiple tools and dies. The only extra thing needed will be scrap trays in different sizes On the left and right end of the system, heightadjustable brackets with linear bearings support a crossmounted aluminum profile. The profile is fastened with standardized clamping brackets and will transfer the motion over the whole width Numerous trays can be mounted. Two rugged nylon Ushape clamps are permanently fastened to each of the trays. The fasteners are designed to slide and fit snug onto the aluminum profile so that exchanging of trays is just a matter of seconds. The length and width of the tray is determined by the size of the die slot.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster consists of a casing with threaded pin and a top cover as solid turned part, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster consists of a casing with threaded pin and a top cover as solid turned parts, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing and a top cover as solid turned parts, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer units consists of a casing and a top cover as stamped parts, a bearing ball and several support balls. In common parlance, these ball casters are also called “UFO” or “Saturn” ball casters, according to their construction type. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of three stamped parts, the casing, bearing shell, 3-prong-buittin-clip and top cover, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / air cargo unit consists of a casing and top cover as solid turned parts, a bearing ball and several support balls. Special model with separate ball cup as an airport ball caster. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a base flange, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a bearing ball and several support balls. To this ball caster is another casing which serves as a body for the spring. Prevent spring loaded ball casters Damage caused by shock loads. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a bearing ball and several support balls. To this ball caster is another casing which serves as a body for the spring. Prevent spring loaded ball casters Damage caused by shock loads. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a bearing ball and several support balls. To this ball caster is another casing which serves as a body for the spring. Prevent spring loaded ball casters Damage caused by shock loads. Dimensions Die Teilung wird ermittelt, indem man die kürzeste Kantenlänge des Fördergutes durch 3,5 dividiert.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / ball transfer unit consists of a casing, a top cover and a bearing cap as solid turned parts, a head flange, a bearing ball and several support balls. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

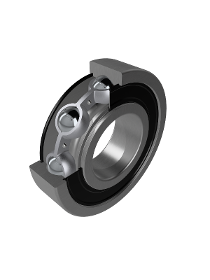

KIS deep groove ball bearings are characterised by their high load carrying capacity and speed stability. Depending on the requirements of your application, they are available in different variants and in both radial and axial design. Our single row deep groove ball bearings are available in open and sealed designs. Open bearings are maintenance-free, while sealed bearings offer better corrosion protection. Single row deep groove ball bearings can support both radial and axial forces. Our double row deep groove ball bearings feature a higher radial load carrying capacity. They are used when the radial load carrying capacity of single row deep groove ball bearings is not sufficient. Axial deep groove ball bearings are suitable for supporting particularly high axial loads. They are available in both single and double direction. Single direction thrust ball bearings can only support axial forces, while double direction thrust ball bearings can support both radial and axial forces.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

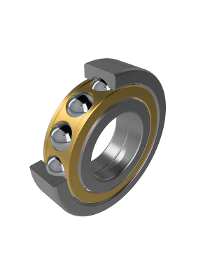

We design our angular contact ball bearings especially for bearing arrangements that have to support combined loads such as radial and axial forces acting simultaneously. As the name suggests, in angular contact ball bearings the forces are transmitted from one raceway to the other at a specific contact angle, oblique to the radial plane. As the nominal pressure angle increases, so does the axial load carrying capacity. Our KIS range includes single-row angular contact ball bearings as well as bearings arranged in pairs. Depending on the application requirement, which for example has a small installation space and requires a rigid bearing arrangement, a double-row design may also be suitable. We are happy to work with you to find the perfect KIS solution for your application.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

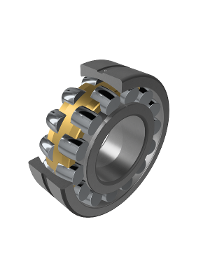

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

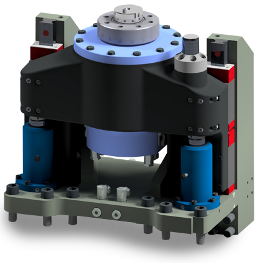

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteResults for

Bearing supports - Import exportNumber of results

43 ProductsCompany type