- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic motor

Results for

Magnetic motor - Import export

STRONG MAGNETS GMBH

Germany

The stator is assembled by many pieces of all kinds of magnets and steel parts. We can provide customers customized stators and various of other magnetic assemblies.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for any application: 24V DC permanent magnet with 110W output power. Combined with the RPL050 planetary gearbox, the result is a compact drive for many industrial and mobile applications. Gear ratios i = 5, 7, 10, 25, 35, 50, 100 Output speeds between 600-30 rpm Rated torques S1 between 1.7Nm and 7Nm Backlash 1-stage <=10 arcmin / 2-stage <=14Nm Protection class IP54 Design B14 If you have any questions or require further information, please contact our sales team.

Request for a quote

RUHRGETRIEBE KG

Germany

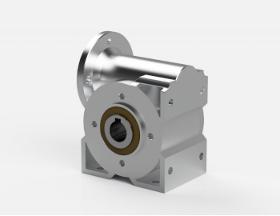

The right drive solution for every challenge: Experience our new modular worm gear, which offers a variety of mounting options and can therefore be adapted to all your needs. With the preconfigured basic components based on our many years of experience, you can implement your drive task particulary quickly. Should your application make special demands on the drive unit, we naturally offer you competent advice and will be happy to assist you in configuring your drive unit Basic version: — Aluminium casting housing — Hollow shaft Ø15 — Ratios: 7; 10; 20; 24; 30; 50; 55 — Permissible torques: 11-13 Nm Customising - Optional equipment: — Plug shaft on both sides Ø10x30mm gen. 5x20 — One-sided plug shaft Ø10x30mm gen. 4x20 — Big flange Ø100/Ø80/Ø60mm — Complete drive units as three-phase, direct current or 24VDC permanent magnet motors

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MERKES GMBH - SMALL MOTORS

Germany

The synchronous servomotors of the series MT are brushless permanent magnet synchronous servomotors with sinusoidal back EMF and with neodym permanent magnets at the rotor. Therefore they are particulary suitable for high-quality servo applications, for example positioning demanding high standards of dynamics and accuracy. Standard configuration of the motors: 2-pole resolver feedback connectors, straight, 1" flange design B5 thermo protection PTC protection class IP65 plain shaft RAL 9005 Further options and equipment are available on request. Maybe options and non-standard equipment can have an effect on the dimensions of the motors. We therefore recommend to consult about it with us before ordering.

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The synchronous servomotors of the series MN are brushless permanent magnet synchronous servomotors with sinusoidal back EMF and with neodym permanent magnets at the rotor. Therefore they are particulary suitable for high-quality servo applications, for example positioning demanding high standards of dynamics and accuracy. Standard configuration of the motors: 2-pole resolver feedback connectors, straight, 1" flange design B5 thermo protection PTC protection class IP65 plain shaft RAL 9005 Further options and equipment are available on request. Maybe options and non-standard equipment can have an effect on the dimensions of the motors. We therefore recommend to consult about it with us before ordering.

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The Series MPM – That makes the difference: — Sustainable reduction of energy costs by efficieny IE4 — Highly efficient usage of material and resources — Reduced type number and lower motor weights — Constant torque covering the whole speed range — Better performance in part load operation — Innovative sensorless speed control# — Suitable for “frequency injection” — Free choice of frequency inverter The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, are achieved. The syn-chronous motor technology in a classic standard motor housing fulfills the economic requirements and making it ideal for speed controlled operations or applications with high duty cycles and/or high partial loads.

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The Series MPM – That makes the difference: — Sustainable reduction of energy costs by efficieny IE4 — Highly efficient usage of material and resources — Reduced type number and lower motor weights — Constant torque covering the whole speed range — Better performance in part load operation — Innovative sensorless speed control# — Suitable for “frequency injection” — Free choice of frequency inverter The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, are achieved. The synchronous motor technology in a classic standard motor housing fulfills the economic requirements and making it ideal for speed controlled operations or applications with high duty cycles and/or high partial loads.

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The Series MPM – That makes the difference: — Sustainable reduction of energy costs by efficieny IE4 — Highly efficient usage of material and resources — Reduced type number and lower motor weights — Constant torque covering the whole speed range — Better performance in part load operation — Innovative sensorless speed control# — Suitable for “frequency injection” — Free choice of frequency inverter The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, are achieved. The syn-chronous motor technology in a classic standard motor housing fulfills the economic requirements and making it ideal for speed controlled operations or applications with high duty cycles and/or high partial loads.

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The Series MPM – That makes the difference: — Sustainable reduction of energy costs by efficieny IE4 — Highly efficient usage of material and resources — Reduced type number and lower motor weights — Constant torque covering the whole speed range — Better performance in part load operation — Innovative sensorless speed control# — Suitable for “frequency injection” — Free choice of frequency inverter The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, are achieved. The syn-chronous motor technology in a classic standard motor housing fulfills the economic requirements and making it ideal for speed controlled operations or applications with high duty cycles and/or high partial loads.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The brand new R-Series Robots are establishing the benchmark for all those tiny to medium duty industrial robots. The compact design and style, as well as business leading pace and work selection create the R-Series Robots ideal for many applications in the course of many assorted industrial sectors. The new light in weight arm, the high-output, high-revolution magnetic motors offer industry leading acceleration and also high-speed functioning. The acceleration rate automatically changes geared to the payload and robot posture to offer the best overall performance with the quickest cycle times. With increasing the robot's maximum range, the rotation range of every axis has been enhanced. The lengthy movement selection equals a larger usable work area with minimum dead-space and larger flexibility. R-Series incorporates any double-seal construction about most axes along with the electro-mechanical contacts that are water resistant, giving the IP67 classification for wrist.

Request for a quoteResults for

Magnetic motor - Import exportNumber of results

13 ProductsCompany type