- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- liquids

Results for

Liquids - Import export

BOOMEX GMBH

Germany

Discover the high-quality bio-ethanol for your bio-ethanol and gel fireplaces. With odorless and residue-free combustion, it ensures clean burning and a pleasant atmosphere in your home. Enjoy the lively play of flames sparked by our bio ethanol.

Request for a quote

BOOMEX GMBH

Germany

Discover the high-quality bio-ethanol for your bio-ethanol and gel fireplaces. With odorless and residue-free combustion, it ensures clean burning and a pleasant atmosphere in your home. Enjoy the lively play of flames sparked by our bio ethanol.

Request for a quote

BOOMEX GMBH

Germany

Discover our exclusive fire gel, specially developed for gel fireplaces, gel burners and Dutch ovens. Enjoy an odourless and safe play of flames that fills your home with a warm atmosphere. Experience the fascinating play of flames in your home – without compromising on safety.

Request for a quote

BOOMEX GMBH

Germany

Discover our exclusive fire gel, specially developed for gel fireplaces, gel burners and Dutch ovens. Enjoy an odourless and safe play of flames that fills your home with a warm atmosphere. Experience the fascinating play of flames in your home – without compromising on safety.

Request for a quote

BOOMEX GMBH

Germany

Discover our exclusive fire gel, specially developed for gel fireplaces, gel burners and Dutch ovens. Enjoy an odourless and safe play of flames that fills your home with a warm atmosphere. Experience the fascinating play of flames in your home – without compromising on safety.

Request for a quote

BOOMEX GMBH

Germany

Discover our exclusive fire gel, specially developed for gel fireplaces, gel burners and Dutch ovens. Enjoy an odourless and safe play of flames that fills your home with a warm atmosphere. Experience the fascinating play of flames in your home – without compromising on safety.

Request for a quote

BOOMEX GMBH

Germany

Biological based lamp oil for kerosene lamps. Bottle with children-safety cap. DIN tested.

Request for a quote

BOOMEX GMBH

Germany

Clear lamp oil for kerosene lamps. Bottle with children-safety cap.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

The filter materials VYON® and GURON® are sintered, porous low-pressure polyethylenes whose polymer particles fuse together at their points of contact. Since 1965, with the founding of the KOPP Filter Technology department, KOPP has been offering its customers individual and tailor-made solutions: numerous filter devices for liquid filtration, filter material for filtration, separation, ventilation and ventilation as well as silencers. The traditional Aachen company relies on the high-quality filter materials VYON® and GURON® - open-pored low-pressure polyethylenes with outstanding positive properties such as physiological harmlessness, temperature resistance, high corrosion and chemical resistance, low weight, environmental friendliness and a favorable cost/benefit ratio. Arguments with which KOPP filter materials have been convincing for decades.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Heating of all kinds of liquids and gases, especially suitable for installation in hazardous areas (ex. areas). Continuous heating by means of heat exchange between the tubular heating elements and the medium. We are experts in customizing process heaters always ensuring to deliver solutions which will be both technically and economically sound.

Request for a quote

BARTSCHER GMBH

Germany

Hygienic, user-friendly, and cost-effective: The integrated infrared sensor enables the contact-free, optimally dosed dispensing of liquid soap.

Request for a quote

BOOMEX GMBH

Germany

Discover the high-quality bio-ethanol for your bio-ethanol and gel fireplaces. With odorless and residue-free combustion, it ensures clean burning and a pleasant atmosphere in your home. Enjoy the lively play of flames sparked by our bio ethanol.

Request for a quote

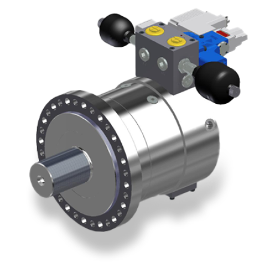

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

The all-in-one solution Already the basic version of the OPTISWIRL 4200 is equipped with a temperature compensation for saturated steam applications. With the optional pressure sensor the OPTISWIRL 4200 has an integrated density compensation available, which even allows an exact measurement of gases and superheated steam with varying process conditions. The additional integrated gross and net heat measurement makes the OPTISWIRL 4200 to be a reliable partner for advanced energy management systems. The OPTISWIRL 4200 was designed for the safety-related applications from the very beginning. It was developed according to the standard IEC 61508 edition 2. The certification is effected within the scope of a Full Assessment by TÜV Süd. Thereby the OPTISWIRL 4200 can be used for continuous volume flow measurement in safety-related applications with classification SIL2.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ up to 16 fully automatic mixing recipes during the unattended night shift ■ scale sizes: 300/600 kgs; 1 g / 2 g indicated scale resolution ■ dosing accuracy: +/- 5 g / +/- 6 g ■ parallel dosing on several scales ■ valve sizes from DN 15 to DN 50 ■ fast adaptation to dosing containers between 75 litres and 600 litres ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound extraction system directly at the dosing point ■ Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 mixes automatically in night mode ■ 2000 doses per day ■ Liquid dosing up to 25 kg batch size ■ Scales with 30 kg or 60 kg capacity and 10 mg or 20 mg indicated scale resolution ■ 50 mg or 60 mg dosing accuracy ■ DN 8 valves ■ Parallel dosing for high speed ■ Barcode-supported dosing ■ Customisable system sizes and container transport systems ■ Integrated environmentally friendly extraction system ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing system for laboratory and small scale production mixes up to 6 kg batch size Space-saving this system combines all advantages of a laboratory dosing system to the production capacity of the larger systems Concordia II – V (C 2 – 5). ■ batch sizes up to 6 kg ■ more than 130 fully automatic mixing recipes during the unattended night shift ■ 7000 dosing cycles per day ■ dosing precision on the 6 kg scale: +/- 5 mg ■ smallest dosable quantity on the 6 kg scale: 20 mg ■ modular design for up to 1000 components ■ barcode assisted dosing ■ high dosing speed through parallel dosing on several scales ■ individual container transport Systems ■ various raw material storage Systems ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Creative and sampling laboratories are familiar with the problem: cramped premises with no alternatives, hardly any space for the extensive ingredients and tight deadlines. Specially developed for office buildings, the modular and space-saving laboratory systems can automate up to 600 components with maximum precision. From now on, fast presentations of mixtures will be a further advantage for your company. ■ 34 mixtures fully automatically in unattended night-time operation ■ Optionally up to 54 mixes ■ 2,000 doses per day ■ Barcode-supported dosing ■ Dosing accuracy with 6 kg scale: ±3 mg ■ Smallest dosing quantity with 6 kg scale: 5 mg ■ Mixtures up to 1 000 ml ■ Quick presentation of dosing results ■ cooled and heated components ■ Modular design for different sizes (100-500 components) ■ Integrated storage system

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quoteResults for

Liquids - Import exportNumber of results

37 ProductsCompany type