- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- large parts

Results for

Large parts - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Storage systems from Lödige provide a total integrated solution for parts and tools to be stored in an efficient and save-spacing saving way. Lödige storage systems can be fully automated to store and transport anything from small parts to very large and heavy aircraft parts and tools. We develop high-throughput storage systems in line with customer requirements to support your dispatch reliability and speed.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

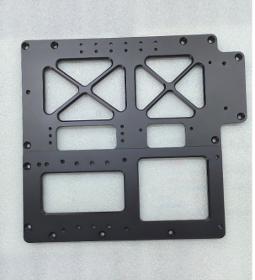

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

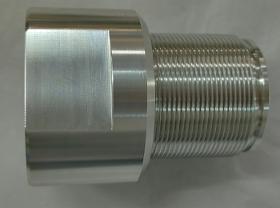

Large mechanical aluminum screw fittings.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssoris used in large machinery parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large machinery parts,Textile machine accessories.China cnc machining workpiece

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

Production of elastic and plastic components for all industrial sectors up to racing technology. No matter if single piece - sample production - small series - large series or the production of prototypes. Almost EVERYTHING is possible - and this means from the smallest miniature component (Ø 1 mm) up to large parts (currently Ø 2500 mm).

Request for a quote

SPANSET SECUTEX GMBH

Germany

Machine elements and casted parts must be turned frequently during the manufacturing process and for shipping. The components are getting bigger and bigger and the demands on quality and time are getting higher and higher. Expensive cranes are often blocked for hours for the challenging turning operations and a large part of the production areas cannot be used during this time. SpanSetsecutex coatings for lifting slings and protective sleeves are used daily for lifting and moving sharpedged loads. For the safe and economical turning of heavy and difficult loads, secutex has now developed the turning slings with the new secuWave coating (patent pending). The unique feature of the secutex turning slings is the new wave profile. It combines the wellknown advantages of secutex coatings – excellent cut resistance and flexibility as well as a very high wear and abrasion resistance

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

HE-JA VERPACKUNGSMASCHINEN GMBH

Germany

Spare parts supply, retrofits, upgrades, consulting and service for HE-JA and Höller/Weldotron machines, all from one source. We have a large stock of critical spare parts in order to be able to help quickly in an emergency. Talk to us, we will help you!

Request for a quote

TROTEC GMBH

Germany

These exceptionally adaptable fans produce a outstanding and persuasive performance in every circumstance. The casing of this condensed fan is manufactured of virtually indestructible polyethylene, which substantially reduces weight making for a sturdy and highly useful fan. The TFV 30 S can be functional and stored in various positions. Its firm condensed shape makes the TFV 30 S suitable for small or difficult spaces. The TFV 30 S can be functional at different angles (0°, 45°, 90°). The turbo fans are very flexible. This perfect combination of rugged casing, high - productive motor, condensed form, adaptable working angles and excellent price makes the TFV S series suitable as modular equipment for restoration and cleaning companies, builders and trade contractors. Features and Benefits of the TFV 30 S carpet dryer: Robust polyethylene housing Double-flow turbine with extra large special axle All internal parts made of metal

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

ORBIS EUROPE

Germany

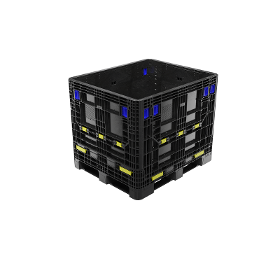

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Chamber dryers are ideal for small lot sizes and intermittent drying. Chamber dryers are suitable for the batch drying of the most diverse goods and for large-format parts with long drying times. The drying process can be individually adapted to the parts by means of the drying duration or temperature. The dryers are fed either manually or fully automatically.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Water-sprinkled spray walls and spray booths with automatic paint sludge filtration system In wet separation, the overspray meets the water film of the spray wall and is thereby bound in the water. The sludge formed by this is discharged using sludge filtration systems. Water-sprinkled spray walls The overspray is sucked in in the lower area of the vertical water drain surface and is bound in water when it meets the film of water. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. In order to replace the water lost due to evaporation, it is recommended to fit an automatic water level controller. The entire quantity of water is fed to the automatic paint sludge filtration system via the disposal pump. A coagulant is added to the water by an automatic dosing unit, as a result of which the paint sludge in the circulating water is disbonded and can be separated more easily. The cleaning of the circulating water takes place in the separately arranged paint sludge filtration system. Depending on the paint system and plant version, the separation system is operated using a full or partial current method. Water-sprinkled spray walls/booths with underfloor paint mist extraction For the painting of large parts with a high paint throughput. The paint mist is sucked in under the grating cover. A substantial part of the overspray is already bound in the water by the constant sprinkling of the entire floor of the basin. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. Optimum capture of the paint mist is guaranteed by the laminar air flow inside the booth. A further advantage over comparable systems is the low water basin height and the associated low foundation depth. The sludge formed by this is discharged using sludge filtration systems. Advantages

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Continuous flow pretreatment plants are designed for high throughput and consist of cleaning stages (degreasing), rinsing stages and possibly layer-forming processes such as phosphatisation. Continuous flow pretreatment Continuous flow pretreatment plants are universally usable. Their high throughput performances in particular make them interesting for many applications. Spraying rings apply different media to the components as they pass through. In the successive zones, therefore, the parts can pass through a cleaning programme tailored to the particular application that guarantees optimum and constant quality. Rippert builds continuous flow plants for small sheet metal parts up to large-scale drag cleaning with a high quality of workmanship. Multi-channel pretreatment plants are also possible, as is combined pre-cleaning by means of robots.

Request for a quote

ABS SAFETY GMBH

Germany

Use this temporary anchorage device as a mobile anchor solution. In just a few seconds, the brass clamps of this anchor, which to a large part is manufactured from aluminium, can be clamped to a steel girder. This device, which only weighs 1.85 kg, protects 1 individual from falling. EN 795:2012, B Simply clamped to a steel girder Flange width: 100 - 330 mm Flange depth: max. 33 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Cutting from small to large Whether turning or milling, small or large parts - Siempelkamp Maschinenfabrik is available to you as a competent manufacturer for your components. Thanks to our many years of experience in machining technology, we oer you the highest quality, precision and technical knowhow for consulting and manufacturing your product. Key features workpiece weight up to 450 t 5-axis turning and milling Advantages certied production quality almost incomparable production possibilities wealth of experience

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

ROBUST, COST EFFECTIVE AND VERSATILEWith a trough vibrator from our TFM range, you get a mass finishing machine that can trowalize large and sensitive parts as required. Alongside an excellent processing result, this machine stands out above all thanks to its great-value purchasing costs. The bowl can also be supplied with a rubber lining. WITH U OR PEAR-SHAPED WORK BOWL TFM vibrators are supplied as standard with U-shaped work bowls with straight walls, which can also be ordered with integrated wedge profile for better mass circulation. Pear-shaped work bowls with double-retracted walls are also available for even greater robustness. VIBRATION VIA CONVENTIONAL IMBALANCE MOTORS Powerful conventional imbalance motors generate the imbalance in the trough vibrators. Your TFM vibrator will have one or two imbalance exciters depending on its size.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Welding construction as required No matter whether pipes, small parts or large components - the welding construction department of Siempelkamp Maschinenfabrik GmbH is able to fulll your wishes thanks to its high-performance machinery. Our welding specialists are able to produce your components using MIG, MAG, UP, TIG, Emanual and electro-slag processes. Numerous certicates attest to the highest quality of our welding work. Key features procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Advantages procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Application of the most ecient welding process for your component Highest quality standards through certied welding work economic production of tubes by our forming and necking machine

Request for a quote

MAYFRAN GMBH

Germany

The patented one shaft crusher with automatic ejector of large parts. Especially suitable for use in machine pump back systems for chips and coolants. Compact and robust design with the Mayfran high quality features. Maximum security for the user, since no manual intervention is necessary. Large parts can no longer block the crusher and interrupt the operation.

Request for a quote

MAYFRAN GMBH

Germany

Large amounts of bushy turnings can be added and processed directly (i.e. from cart dumpers). The shredder with vertical cutters(normal or fine) is especially suitable for crushing tough materials and is fitted with an automatic large part ejector.

Request for a quote

ZOKKO

Germany

We design and manufacture successful non-food departments The development of a non-food product category in stores is an effective way to increase the profit of the freight outlet. Market analysis shows that in stores with a small selling space, the development of this product category leads to an increase in sales from turnover up to 10% and from income up to 15%. For a large retail space, this figure can be up to 40% of turnover and up to 50% of income. Non-food products increase customer loyalty, this is a large part of the goods, the need for which at one time or another arises from each customer. If they are on sale, the buyer saves time - he does not need to visit another store. Professional design of non-food racks, taking into account the principles of commodity neighborhood, the correct determination of the number of running meters for product categories, the rules for the direction of movement of buyers Welcome! vl@zokko-eu.com

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This patented system equipment allows the workpieces to protrude beyond the curve dimension. Gentle and smooth running transport is guaranteed, from the small part to large surface workpieces. The picture shows a VEN TRANS CURVE application for the targeted and space saving return of large format workpieces by means of a 180° conveyor belt curve. The transport curves are available in various dimensions and angles (20 - 200°). VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Efficiency and quality of this innovative cleaning system are impressive, from the three-dimensional small parts to large format workpieces in large batch sizes. The performance of the CO2 ice jet is especially convincing when cleaning plastic workpieces. The shown surface plant offers optimum noise emission values of approx. 80dB(A) due to the patented noise protection system comprising follower-type bulkhead partitions. A cleaning jet consisting of a mix of compressed air, CO 2 and CO 2 ice particles causes the soiling on the surface to become brittle. The thermal tension loosens cohesion and detaches the soiling from the workpiece surface. The cleaning jet guarantees the removal of soiling without residue. The DUST FREE and PERFECT applications optimally meet the requirements of the subsequent downstream surface quality, offering maximum thoroughness from dust removal through to cleaning. This process allows gentle cleaning of virtually all components, therefore, it is an alternative to aqueous power washing. Patented detail solutions form the basis for this mature system technology. Small workpieces are reliably held in place by the special hold-down system. The Venjakob pump station developed for this task guarantees the process reliable supply of liquid CO 2 from a low pressure tank system to the cleaning module. A clear advantage of the CO 2 cleaning system over the conventional aqueous cleaning process is its relatively small space requirement.

Request for a quote

SCHULTE LAGERTECHNIK

Germany

The storage of car parts requires both solutions to accommodate bulky goods and the ability to store sensitive goods (such as already painted body parts) without damage. Whether it is packed goods, body parts, tyres or rims - with installation kits from SCHULTE Lagertechnik everything is in perfect hands. — tyre-protecting storage through optimised tyre cross beams or storage on rounded wide span spars — Racks for small, medium and large parts storage — all car racks have the 25 mm grid perforation — Can be combined with the entire connector system — various accessories — special car shelf sets — Construction of multi-storey racking systems possible — individual adaptation to different wheel, tyre and rim sizes — quick assembly by simply plugging in the levels — tyre-protecting storage of the wheels through specially shaped cross beams — optimised height 2,750 mm for the storage of SUV wheels — variably applicable for wheels with 550 - 750 mm Ø

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

As an experienced manufacturer of sandblasting halls and facilities of blasting houses, we offer with our team, problem solutions tailored to your needs and individual case worked out. Price on request

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

It is a system that is preferably used for small blasting and glass decorations. The closed blasting circuit, which allows dust-free operation (particularly interesting for sandblasting work on already installed objects), is advantageous. The system of the "multi-CIean master" means e.g. The solution for the blasting of small surfaces on large parts of machines and vehicles, which can not be disassembled or transported into a blasting space. Due to its extremely light and compact design, it is also possible to use it on construction sites, scaffolds or e.g. Pipelines possible. This system also offers an alternative for cleaning with toxic chemicals or for complex grinding or brushing. A thorough cleaning or removal of rust, scale or similar deposits can also be carried out without having to perform costly and costly disassembly.

Request for a quoteResults for

Large parts - Import exportNumber of results

32 ProductsCompany type

Category

- Sandblasting equipment (3)

- Laser - cutting and welding machines (2)

- Components and parts for large household appliances (1)

- Adjustment - machine tools (1)

- Boxes, plastic (1)

- Clothing accessories (1)

- Food industry packaging machinery (1)

- Forming, rubber - machinery (1)

- Offshore construction (1)

- Precision measuring instruments (1)

- Rolling machines (1)

- SMALL METAL PARTS (1)

- Seals (1)

- Shelving, storage (1)

- Steel & Metals (1)

- Straps, woven - industrial (1)