- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial plastics

Results for

Industrial plastics - Import export

WERNER LANGER GMBH & CO. KG

Germany

Through a long-term cooperation with advertising producers, we have developed a wide range of products for the office and promotional product industry. We produce plastic parts for various sectors such as catering / restaurants, computers, household, desk, sports, and games. Our major partner is the company Plastolan. If you want to learn more about Plastolan, please look just right on the corresponding website ( www.plastolan.de).

Request for a quote

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too ,Manufacture of silicone or aluminium moulds ,Gas internal pressure procedure (GIP) Processing of sheet plastic (cutting, milling, bending) More information available at https//www.geck.de

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction The Schulz ball caster „Blue-Line“ with a housing made of certified plastic and a gap-free, closed cover (without dirty edges), a plastic or stainless steel carrier ball and several support balls has been specially developed by us for use in the food industry. For this purpose they have the signal colour blue. The Schulz plastic ball castor „BlueLine“ is particularly easy to clean due to the new design with several dirt holes in the housing. Dimensions The pitch is determined by dividing the shortest edge length of the conveyed material by 3.5.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

With our delivery program “Screws for direct screwing” we deliver a great variety of thread rolling screws in different implementations. In doing so we realize small lot sizes and short-term delivery dates. Upon request we also introduce customer-oriented warehousing also in your company. Apart from the many advantages you can save time and money. We provide: KTG screws for thermoplastic materials: single pass thread or double pass thread (high/low); head shapes with cross or 6-star (similar Torx). Tapping screws: longitudinal slot, cross slot, cross-head-combination slot or 6-star (similar Torx). DIN 7981, 7982, 7983 or to the new ISO standards; special tip-styles, e.g. with with pressed washer. Combination screws with undetachably washers: According to DIN 6901. Self-tapping screws: According to DIN 7500. Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry...

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

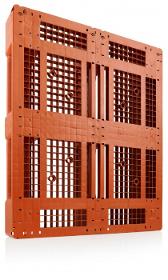

ORBIS EUROPE

Germany

Durability, cleanliness, product protection – plastic pallets for food and beverage applications need to meet high standards and requirements. ORBIS Europe plastic pallets are designed to convey aluminum and steel cans, glass and plastic bottles, can ends and other rigid packages on many palletizers and conveyor systems. - Compatible with existing supply chains in different geographies - Easy to clean all-plastic design - Reusable with a long service life - Tapered 4-way entry - Options available (e.g. hot stamp, grommets) We offer a variety of footprints and designs that fit into existing processes and systems: 1180 x 1265 1120 x 1300 1120 x 1420 1000 x 1200 From Wood to Plastic for the Environment Switching from wooden pallets to plastic pallets improves workplace safety and cleanliness in your operations. ORBIS plastic pallets are durable and make a tremendous number of trips before being recycled.

Request for a quote

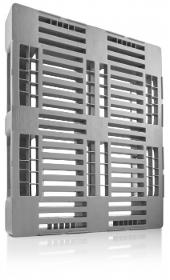

CRAEMER GMBH

Germany

The L3 plastic pallet is the ideal load carrier for use in intralogistics. This plastic pallet convinces with high load capacity of up to 2.000 kg in high rack. Thanks to a standard fitting with Palgrip® anti-slip strips on the top deck, the load is safely stored on this pallet - even in inclined position. The constant high quality despite increasing circles makes the pallet highly economical, it remains error- and maintenance-free. The closed Palgrip® anti-slip runners of the L3 plastic pallet enable smooth running on all standard conveyor elements in intralogistics processes. Dimensions L x W x H: 1200 x 1000 x 160 mm Weight: 26,0 kg Material: HDPE Load capacity: static 7500 kg, dynamic 2000 kg, In Racking System 2000 kg Reinforcement Profiles: 5 Colour: light grey / light blue or basalt grey / light blue Runners: 5, welded Palgrip®-Anti-slip top deck Option: — Rim options: Without, 7 mm — Palgrip® anti-slip runners

Request for a quote

CRAEMER GMBH

Germany

The D3 / D3-5 industrial pallet it the perfect combination of multiple equipment options, low tare weight, and an attractive price-performance ratio. The industrial pallet is available as a 3-runner pallet (D3) or 5-runner pallet (D3-5) and impresses with versatility: It was specially developed for box applications in the automotive industry, and has proven itself as a universal pallet. The addition of reinforcement profiles can further increase the load-bearing capacity of the pallet. Characteristics: Ideal for lightweight to medium weight loads Low tare weight of just 14 and/or 15kg With 22mm outside edge, the D3 / D3-5 has interior dimensions of 1200 x 1000mm for box and blister applications Chamfered edges on both sides of all runners for optimal handling with fork lift trucks Options: Corrosion-protected reinforcement profiles, for a load-bearing capacity of up to 1,250kg in high rack Rims: without, 7mm, 22mm outside, 22mm vertical RFID transponder Anti-slip plugs

Request for a quote

CRAEMER GMBH

Germany

The H3 plastic pallet is the industrial-sized version of the H1 Euro pallet. This hygienic pallet is a proven choice primarily in the food and meat processing industry, however it is also suitable for transportation and storage of medium weight loads at temperatures down to -40°C in the non-food sector. The H3 plastic pallet is also available in a conductive version for use in the automotive, electrical and chemical industries as well as by their suppliers – to protect against electrostatic discharge (ESD). Characteristics: Available with 3 runners Ideal for medium weight loads High bending strength Ideal for transportation and bagged of sack goods or cardboard packaging Excellent cleaning properties Chamfered edges on both sides of all runners for optimal handling with fork lift trucks Options: Welded runners for a high standard of hygiene and smooth running on roller conveyors Rims: 7mm RFID transponder Palgrip® anti-slip coating under the runners ESD version

Request for a quote

CRAEMER GMBH

Germany

The D3 ECO / D3-5 ECO recycled pallet is perfect for the distribution and storage of medium loads. Dimensions L x W x H: 1200 x 1000 x 150 mm Weight: 14,0 kg - 19,0 kg Material: HDPE Load capacity: — without reinforcement profiles: static 5000 kg, dynamic 1000 kg, in racking system 400 kg — with 4 reinforcement profiles: static 5000 kg, dynamic 1500 kg, in racking system 1250 kg Colour: black Runners: 3 / 5, unwelded All runners have chamfered edges on both sides for ideal use with fork lift trucks Option: — Rim options: Without, 7 mm, 22 mm, 22 mm outside — Reinforcement profiles: 0,3, 4 — Palgrip® anti-slip runners — Pop-Ups as interlocking support for stacking of empty pallets — Anti-slip plugs from top to underside of deck — Integration of RFID transponders

Request for a quote

CRAEMER GMBH

Germany

The CR3 / CR3-5 industrial pallet with integrated reinforcement profiles is an all-rounder in the heavy-duty category and can be found in both pooling and internal logistics of many sectors. Thanks to its robust design and versatility it is ideally suited for high racking warehouses or on automated conveyor technology. Without steel profiles, the 3-runner CR3 and the five-runner CR3-5 are ideal for applications where high performance is crucial, but withouth the requirement for extreme load-bearing capacity. Characteristics: Available with 3 (CR3) or 5 runners (CR3-5) High load-bearing capacity for heavy-duty applications Dimensionally stable with first-class bending parameters Chamfered edges on both sides of all runners Palgrip® anti-slip strips on the top deck Options: Corrosion-protected reinforcement profiles, for a load-bearing capacity of up to 1,400kg in high rack Rims: without, 5mm, 22mm RFID transponder

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow ultrasonic - as a replacement for the current and widely used standard measuring variant with impeller, turbine or vortex - now makes contactless measurement according to the ultrasonic principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. Alternatively, the mechanical flow measurement according to the differential pressure principle is available with the proflow mechanical. Easy to integrate in machines and plant lines 4 or 6 x consumer channels (forward/return) 1/2“ With LED-display on fl ow sensor Temperature measurement PT 1.000 Big RED/GREEN Status LED 1 x main connection 1“ Flow rate each channel 1 ... 30 l/min (no „overload-risk“-> 60 l/min possible]) Operating temperature: 0 ...120 °C

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Our gwk engineers are passionate about developing technical solutions and this is what we as manufacturers want to prove in the area of cooling towers with our gvk/ghkv series. We see it as our task to understand the entire process of our customers. Therefore we have focused on quality and longevity for the products gvk/ghkv. The cooling towers are part of a central cooling tower system, supplied turn-key and regulated with a freely programmable microprocessor control system or programmable logic control. They are used for dissipation of excess heat from production systems with a higher temperature level and they operate on the principle of evaporation. This is an important consideration for environmentally conscious industries.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Every industrial production requires energy in order to make products. Often, electrical or primary energy is induced as heat, used for operation and must then be dissipated, converted or destroyed. Our gwk process engineers analyse and calculate production processes and the overall thermal periphery with the objective of lowering the necessary energy by means of energy recycling, of reducing the energy requirement at the individual stations, of converting energy or using it several times and dissipating it sensibly. The result is considerable energy saving, which results in cost-cutting and contributes to preserving the environment.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND NEARLY MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow mechanical - as a replacement for the current and widely used standard measuring variant with impeller or turbine - now makes mechanical measurement according to the differential pressure principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. A completely non-contact flow measurement based on the ultrasonic principle is available with the proflow ultrasonic. Robust flow measurement in consumer return line PT 1.000 temperature measurement in consumer return line 6 x 2 consumer channels 3/4“ female screw thread 1 x 2 main connection 1“ female screw thread Available in three temperature variants: operating temperature up to 100°C, up to 160°C and up to 180°C Max. flow rate each channel:: 25 l/min or 50 l/min

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNOTRANS SOLUTIONS GMBH

Germany

Whenever the process requires high temperatures and the advantages of water as heat carrier (best heat conductivity properties, inexpensive, low viscosity) are to be used, this construction series is the best solution. Absolute reliability, high regulating accuracy, easy operation and a favorable price /performance ratio: apart from the versatile performance features a modern temperature controller has to fulfill, these are the key criteria for the temperature controllers teco wh/whx. As one-circuit and multi-circuit units, our modular temperature controllers in the teco whx series cover a wide performance spectrum. Heating capacities of 12 to 600 kW, max. possible cooling capacities up to 1460 kW* and pump flow rates of max. 200 m3/h are impressive basic data of these technically sophisticated temperature controllers for operation with compressed water up to 220 °C.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMPTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. In the selection series we used the most frequently selected equipment features and heating performance of the proven premium series advanced. The protemp selection temperature control unit is particularly suitable for the supply of multi-circuit water distributors and is designed for the display of up to 6 external proflow temperature control channels.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

With the decentralised solution, gwk adds a machine series that offers a high level of flexibility for numerous applications to its portfolio. The customer can individually and precisely set the ideal cooling water temperature for every production machine and for every process in production. Thanks to the direct connection to the consumer, there are no thermal losses, but instead a high flow rate and constant pressure. The weco wd series consists of easy to operate plug&play machines that can easily be installed and commissioned. Three processes can be run with the solution: Free cooling, refrigeration process for low temperatures down to -5°C and temperature control up to 90 °C –everything can be chosen as desired. There is a total of four models with cooling powers between 14 kW and 36 kW (at 15 °C feed flow temperature) and heating powers between 9 kW and 36 kW.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The integrat 80 is used for the modular temperature control with water up to 140°C in the basic version with up to six temperature control circuits to be operated completely independently of each other. The basic version can be expanded with extension columns and up to 24 temperature control modules. As an option, the temperature control circuits can be extended with the 4-way distributor vtc with flow and temperature measurement. Thus, a maximum of 96 temperature control circuits can be monitored with the vtc 4-way distribution system. In conjunction with the standard heating control system used as standard, a homogeneous temperature profile on the mould cavity surface is achieved in an extremely energy-efficient manner, as well as with constant cooling by using a motor valve. As an option, the pumps can also be operated with frequency control unit. This improves the procedural results and contributes to energy savings.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Dynamic mould temperature control is a temperature control method that allows temperature variations within the cycle and is also known as “variotherm temperature control”. While this method has been known for almost forty years, it has only undergone a dynamic development in the last few years. This is due to the increasingly exacting quality requirements of consumers (e.g. prevention of visible joint-lines, gloss variations and other surface defects) and the use of plastic materials in new applications. When a temperature control system is selected it is important to mind that it matches exactly with the application and that the economic benefit justifies the technical efforts as well as the energy consumption.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

MULTI-ZONE TEMPERATURE CONTROL- AND MONITORING SYSTEM WITH NON-CONTACT FLOW MEASUREMENT. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using the frequency inverter, the already high basic efficiency is optimized and the pump characteristic curve will be optimally adapted to the respective operating conditions. The flow measurement of the individual temperature zones is carried out using noncontact measurement technology according to the ultrasonic principle.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The patented gwk solution includes cold water temperature controllers that can be operated without glycol in the temperature range between 0 °C and 25 °C. The user can select between two models that are differing in cooling capacity and flow rate. A precise microprocessor control with simultaneous indication of nominal and actual value, the simple one-touch operation, optional interfaces at the front panel and external sensor connection, splash-water proofed electrics and the cabling with CEE-socket ready for connection make the unit ready for immediate use. Leak stop operation, mould draining, acoustic alarm, automatic filling and top up, additional manual filling possibility for conditioned water, strainer in the cooling water connection and parts out of corrosion resistant materials that are in contact with the medium are part of the comprehensive standard equipment.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The higher process temperatures, the higher the technical requirements for the temperature machine. Decades of experience in construction of temperature machines for heat carrier oil applications up to 400°C makes us the preferred partner of many customers for applications of this kind, particularly in the area of pressing and extrusion. Dimensioning of our teco tt/th series up to 400°C is based on DIN 4754. Design and technical configuration of all temperature controllers are based on the requirements of this norm. Exact film temperature calculation ensures, in combination with flow monitoring, efficient and at the same time reliable operation in all operating conditions. A lockable filter in the circulating medium return line is a standard installation; another installed feature is an expansion vessel with a cold oil container for reliable prevention of damage by oxidation due to oxygen accumulation in the heat carrier.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Brand-new perspectives and possibilities are offered by the dynamic temperature control with CO2. This new and environmentfriendly procedure really provides a solution for heating and cooling of complex and thinwalled moulded parts. By using gaseous media for heating and cooling processes, soiled cooling channels are now a thing of the past. Basically it is true that gaseous media have the disadvantage to be bad heat carriers. This applies at least to air that is only used for cooling processes under special circumstances. But in contrast, if the opportunities of CO2 are exhausted properly, it offers an interesting alternative to conventional water temperature control.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using an optional frequency inverter, the already high basic effi ciency can be more optimized and the pump characteristic curve can be optimally adapted to the respective operating conditions. PROTEMP SERIES 1-4 ADVANCED Water temperature control unit up to 95°C -140 °C Cooling capacity: 105 - 717 kW Heating capacity 9 - 50 kW Digitization concept „protemp connect 4.0“ Dual frequency version (50/ 60 Hz), motor IE3 class Energy consumption display Pump speed control OPC UA interface

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Absolute reliability, high regulating accuracy, easy operation and a favorable price/performance ratio: apart from the versatile performance features a modern temperature controller has to fulfill, these are the key criteria in the teco wi temperature controller series teco wi. As one-circuit and multi-circuit units, our modular temperature controllers in the teco wi series cover a wide performance spectrum. Heating capacities of 12 to 1000 kW, max. possible cooling capacities up to 3460 kW* and pump flow rates of max. 300 m3/h are impressive basic data for these technically sophisticated temperature controllers for operation with compressed water up to 150°C. This series is mainly used for roller temperature control (foils, paper, rubber etc.).

Request for a quoteResults for

Industrial plastics - Import exportNumber of results

55 ProductsCompany type

Category

- Plastics - machines and material for industry (29)

- Pallets (6)

- Plastics - industrial machinery and equipment (5)

- Plastics - industrial products (3)

- Plastics - construction industry (2)

- Gears (2)

- Screws (2)

- Moulds, plastic and rubber industry (1)

- Plastic products for the vehicle manufacturing industry (1)

- Castors, swivelling (1)

- Electroheat - machines and equipment (1)

- Goods handling systems, continuous (1)

- Magnets (1)