- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic supplies

Results for

Hydraulic supplies - Import export

ACE STOSSDÄMPFER GMBH

Germany

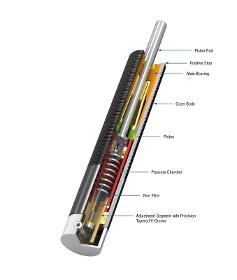

Adjustable Compression Force max. 3,500 N Stroke 15 mm Precise adjustment for any type of application: The VC model of hydraulic feed controls is ideally suited for the precise tuning of constant feed rates. The thread of the outer body of this closed hydraulic element allows simple assembly. Designs with a smooth body can also be supplied. As the hydraulic oil is forced out through the throttle opening, a constant feed rate is achieved on the stroke, which also avoids the stick-slip effect. In the models up to 55 mm stroke, the tried and tested rolling diaphragm, known from ACE shock absorbers, serves as a dynamic seal, as volume compensation of the piston rod and as a reset element.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

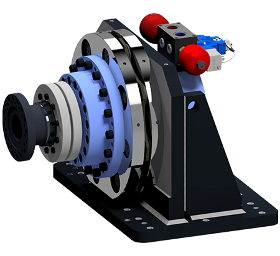

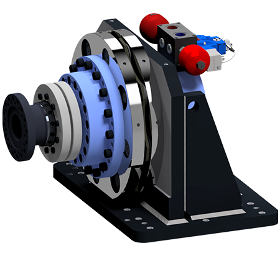

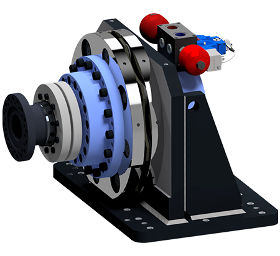

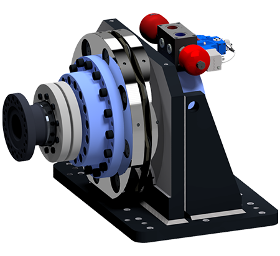

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

Product characteristics of the Disc clutches The shifting clutches mostly serve as a connection that can be activated or disconnected between the power and work units, such as the gear and pump, or in similar installation situations. The disconnection is achieved via the system's existing media supply. (hydraulics, pneumatics) Areas of use of Disc clutches The disc clutches are used in mobile applications, agricultural and forestry machines, sweeping machines and many other areas in mechanical engineering.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With press capacities between 15 and 500 MN, Siempelkamp's closed-die forging presses oer the optimal solution for numerous application areas. The optimal relationship between press dimension and press force oers our customers maximum benets. Best process and system parameters are the guarantee for high dimensional and repeat accuracy. Siempelkamp supplies hydraulic closed-die forging presses for many dierent application areas. According to the application area, guidance accuracy, cycle time, eccentricity, and speed are optimally adjusted with one another. Depending on the customers' requirement, Siempelkamp's closed-die forging presses are available in dierent designs - as push down and pulldown presses. If desired we can supply these presses as part of a complete solution, from the press segment to the forging plant.

Request for a quote

RUHFUS SYSTEMHYDRAULIK GMBH I.L.

Germany

Power units and Control Systems Ruhfus Systemhydraulik GmbH specialises in the production of special solutions in the field of hydraulic units for industrial use. In order to be able to optimise the product to meet your requirements, you will be supported during the whole project phase by our competent team. Ruhfus Systemhydraulik GmbH can supply hydraulic units with tank sizes of up to 10,000 litres capacity. For this we use DIN oil tanks but also special tanks that are individually adapted to your needs. Here it is immaterial whether the oil tank is made of steel, stainless steel or aluminium. For special designs such as table valves, tank support frames, supporting structures for motor pump units and many more special components connected with your hydraulic unit we are of course likewise the right people to contact. For each of our hydraulic units, 3D models are generated beforehand which can be made available to you. From these you can plan earlier the field piping, possible foundations or building and also transport or other matters in detail. For the drives of our hydraulic units we use standard electric motors with a power of up to 80 kW. On request the motors can also be equipped with a frequency converter. As the valve technology, as well as the oil supply unit, are always subject to customer-specific requirements, limits are always hard to define here. As far as possible only two limits should not be exceeded, on the one hand a maximum volume flow of 275 l/min and on the other a maximum system pressure of 315 bar. Furthermore we can offer you the supply of a complete system of cylinder and hydraulic unit to electric control. If you a seeking a competent partner in the “complete solution” area, we will be glad to support you with our team. 3 D Models

Request for a quoteResults for

Hydraulic supplies - Import exportNumber of results

11 ProductsCompany type