- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hard metals

Results for

Hard metals - Import export

CARL FRIEDRICH USBECK KG

Germany

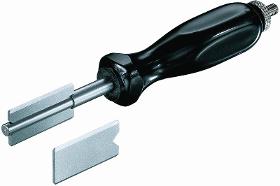

plastic handle*interchangeable blade*made from hard metal*length 185 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*for tubes up to 30 mm Ø*with wheel made from*hard metal

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ Very hard once dried ✔ Hydrophobic ✔ Low Viscosity ✔ Great price ✔ Clear coating ✔ Application temp.: 80 - 110°C ✔ For glas, ceramics, ABS, ... Our GK-I hot melt dispersions is tailored for heat transfer printing. With a rather high activation temperatur is results is very durable bonds once applied. It can be used well with toner-based prints. This adhesive is great for heat transfer printing onto glas or ceramic products like wine or spirits bottles as well as promotional or cosmetic products made from ABS. Furthermore, it offers self-crosslinking capabilities which increase the adhesion even further. It shows great resistance against water and heat. The particles in this dispersion are fine dispersed and result in even and repeatable results.

Request for a quote

WOMA GMBH

Germany

The highpressure pumps of the Z series deliver operating pressures up to 1,500 bar. With a high number of pressure and nominal flow rate combinations, the pumps are preferably used in industrial cleaning, paint stripping and also in descaling.For pumps with an operating pressure of more than 1,000 bar, hard metal plungers are used, which are particularly stable in order to guarantee a long service life and thus low maintenance costs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTHER TROWAL GMBH&CO.KG

Germany

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results. APPLICATIONS: Orthopedic implants (medical engineering) Turbine blades (for airplanes as well stationary turbines) Precision components, for example, for pumps and compressors Work pieces made from tungsten carbide and other hard metals Fan wheels for turbo chargers (automotive industry) Sintered components, etc.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Developed by IBK Wiesehahn, the secondary friction connection seal with H-profile has created an area of application in the industrial branch. The successfull conzept of “secondary friction connection” is based on the separation of bracing and sealing. Every functionary of the seal meet only one function. The seal is made of hard metal-profile and elastic sealing-material. The sealing-material is measured, that after reaching the block storage, the recovery behavior fully exists. A overpress of the sealing-material is basically excluded. Benfits of IBK SAFE-H® Seal: Secondary friction connection (block storage) Seal is chambered (secured against exhaust) High resilience of the flange connection Indenpendently pressure stage dimensions Easier to install regarding centring gauges Simplified warehousing High temperature resistance (up to 1000°C) High pressure resistance (up to 525 bar) Possibility of redefinition of the sealing zone with repair set

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We constantly have a large supply of HM replacement segments and HM bars in stock and also manufacture spare parts which fit scrapers made by other producers. Production of special segments based on drawing possible construction possible in hard metal, HM ceramic and ceramic Spare parts for the following manufacturers also in stock Indutechnik, Schulmeistrat Industrie Technik, Masch, Belle Banne, Manuflex, Duroflex etc.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The housing is made of folded stable sheet steel and welded. In the cabins 2 workports with built-in rubber sleeves (easily exchangeable) are incorporated. The cabin is equipped with a blast hose, nozzle holder and nozzle 1 made of hard metal. For the different requirements are made of hard metal nozzle with a diameter of 0.8 mm, 1.0 mm or 1.2 mm for selection. All blasting medium-pressure vessel (1 - 3 Tank System) have a volume of 2 kg and provided with a closure cap. In all systems, a pressure reducing valve and a pressure gauge for setting a constant jet pressure, and compressed air supply are fitted with plug-in nipple. All systems are equipped with a pneumatic foot switch for turning on and displaying the blasting process.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

This is the ideal piece of equipment for blasting small and even smaller surfaces of glass and metal for matting, fettling, cleaning, polishing and drilling. All mineral media such as corundum, glass beads, cullet, silicium, walnut and plastic granules in the grain size range of 0 - 300 μ can be used as blasting agents. There is a selection of hard metal nozzles with a diameter of 0.8 mm and 1.0 - 1.2 mm as well as 1.5 mm for various requirements.

Request for a quoteResults for

Hard metals - Import exportNumber of results

13 Products