- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handling systems

Results for

Handling systems - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Solutions for the transport and handling of parts. The question of how surface coating plants can be optimally integrated into a production environment arises with ever increasing frequency. Rippert offers its customer an ‘everything from one source solution’ here. The company’s own engineers develop coordinated solutions for the transport and handling of parts together with the customer. Simulation is thereby often the right tool for recognising the full potential of these possibilities. From frying pans to heavy workpieces from the wind power sector, Rippert has already ‘taken it all in hand’. We work on concepts in which industrial robots substitute or supplement the classic conveying equipment in coating plants. For handling tasks we often see the necessity for systems that work adaptively; this means that, for example, image processing systems must recognise the accurate position of parts in two and even three-dimensions so that a robot can pick up inaccurately positioned parts.

Request for a quote

SMI HANDLING SYSTEME GMBH

Germany

mini smilift, allows you quick and frequent movement of loads of up to 60 kg either in cartons, boxes, and bins or as individual items such as plates and machined parts. This compact unit is light and flexible with one-hand-control for pick and place applications in frequent handling operations. It can be equipped with a range of attachments for use with many types of load in production, warehouse and despatch areas. mini smilift is easily and quickly installed and can be integrated into existing installations and work flows.

Request for a quote

SMI HANDLING SYSTEME GMBH

Germany

smilift equipment is utilised for simple and quick product handling. The gripping and lifting of the loads is implemented by means of vacuum in a work process where only the lowest amount of steering effort is required. Whether dealing with boxes, sacks, barrels, slabs or other components, the smilift is the right solution. The equipment can also be supplied in a stainless steel design or for utilisation in explosive areas.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Quality at every level Safe transport and short throughput times — Lödige‘s material handling solutions easily accommodate all the demands made on them whether within the paint shop or in provision and intermediate storage after the painting process. Your advantages using Lödige solutions in the paint shop: Materials handling in multiple dimensions Connection to intermediate store Connection to body shell store Work stations Internal and external materials handling systems Materials handling systems and control technology from one source

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Fully automated storage In the automotive industry, storage in high-bay warehousing and precise, sequential provision are a vital part of the production process. Your advantages using Lödige solutions for efficient storage and order picking Custom-made racking systems Optimum use of space Storage for every sort of component Connection to internal materials handling systems Storage, materials handling and control technology — all from one source Quick and safe storage

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Smooth final assembly The many different processes included in final assembly require precisely timed provision of parts and ergonomic support for manual work. Your advantages using Lödige solutions during final assembly Ergonomic work platforms Connection to high-bay warehousing Efficient preparation of different assemblies Linked materials handling systems Quick access to assemblies in intermediate storage Automation

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lödige supplies logistic systems specifically intended for handling parcels for air cargo. Our parcel and mail handling systems enable peaks in demand to be dealt with effectively on a daily basis. We adapt our high-throughput, space-saving systems to your specific requirements, attaching particular importance to quality and reliability in the process. At a recently completed parcel handling facility in Europe, Lödige installed a new sorting system that can handle more than 2,000 items per hour. The innovative sorter system was built in cooperation between Lödige Industries and Vanderlande and allows for faster handling of all post, express and pharmaceutical consignments. Lödige’s innovative system enables state-of-the-art parcel handling even in space restricted locations.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Profitable turn-key systems Accuracy, reliability and throughput are essential for the success of any material handling in industrial processes. Lödige Industries provides integrated solutions for an efficient material flow from goods-in, through the production process and goods-out, including tracking and stock control functions throughout. We plan, install and commission these solutions and provide an effective life-cycle service support to strengthen your competitive edge. Working closely with our customers we plan, simulate and implement conveyor solutions and turn them into profitable turn-key systems. Thanks to our industry-specific expertise, we optimise your material flow operations, increase the performance of your system and help to reduce operating costs significantly. We are unique in providing the complete solution with in house expertise: System analysis, planning, design, manufacture and supply of material handling systems, management software, installation, commissi

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

TRAPO GMBH

Germany

4- or 6-axis jointed-arm robots of various well-known brands are acting highly flexible. The high-speed systems palletize, sort, load and commission fast and high-precision single pieces, rows, partial layers or complete layers. - Low space requirement - Flexible use for various applications - Product and industry independent: Mature gripper technologies transport a wide variety of goods - Suitable for different packages and load carriers - Set on rails, the jointed-arm robot moves to different palletizing positions - Application-oriented, flexible combination of the optimally complementary technical properties of high-speed palletisers and robots

Request for a quote

TRAPO GMBH

Germany

Our high-capacity portal palletizers act in a material-caring manner on three servo-linear axes within cubic space. We develop, design and manufacture portal robots in our in-house production facility in Gescher-Hochmoor. We are a specialist in the high-care segment -with portal robots made of high-grade steel.

Request for a quote

TRAPO GMBH

Germany

As a supplier of complete systems, TRAPO AG supplies modular High-Performance-Pick & Place-Systems that combine components such as robots, frame units, camera systems and conveyor technology. The modular system can be adapted to different framework conditions and thus covers almost any application. The TRAPO HPPS series forms the heart of the modular picker cell. The high-performance picker line combines maximum performance, individual TRAPO gripper technology and proven know-how, for example in the field of hygiene design.

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

EH 100 JDN Monorail Air Hoists Carrying capacities: 10 t up to 115 t per unit According to application JDN Monorail Hoists can be deployed as Double Lifting Gear: working in parallel as for example in BOP handling systems or working in tandem connected by a coupling rod as for example for handling grinding rollers in the cement industry. Two versions, for each of the 75 and 100 tonne lifting capacity products in the EH range are now available in both double trolley as well as the previously available 4 trolley traverse drive versions. The new twin trolley drive versions, which offer more compact units for operation where limited space is available, are designated as EH 75 C and EH 100 C. Standard Features ideally suited for working in hazardous areas (explosion protection) insensitive to humidity dust and temperatures from -20°C to +70°C low headroom, compact design favourable air consumption world wide service Special Features If you don’t find the right hoisting system for...

Request for a quote

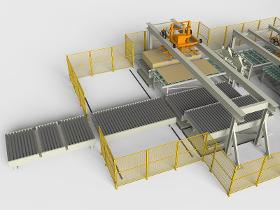

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards to be coated are fed to the raw-board-handling section where they are separated to allow their surfaces to be cleaned. Features, function A forklift truck is used to place the board stacks on to a roller table from where roller conveyors or horizontal transfer carriages equipped with roller conveyors transport them to one of the two separating station's places. A suction carriage removes the top board from the stack and places it on a conveyor that takes it to the surface-cleaning machine. Advantages The two redundant stacking places allow the short-cycle press to be supplied without interruption. They make it possible to feed new stacks of boards without the need to shut the machine down

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001. Aluminium raw black, plastic coated bow-type handle

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

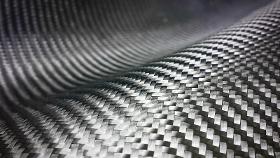

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Economic and safe: Hydraulic bolt tensioning systems Single clamps or small clamps for opening and closing reactor pressure vessels or other primary circuit components As a specialist for the design, construction, supply and maintenance of highly automated bolt tensioning systems, we offer our customers demand-oriented solutions for opening and closing pressurized and boiling water reactors as well as other primary and secondary circuit components in nuclear power plants. Our range of services includes single and multiple bolt tensioning devices, bolt turning and handling systems, bolt and blind hole cleaning systems. Siempelkamp bolt tensioning machines reduce your operating sequences for opening and closing to less than 50 % compared to conventional methods

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001.

Request for a quoteResults for

Handling systems - Import exportNumber of results

53 ProductsCompany type