- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gray iron

Results for

Gray iron - Import export

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

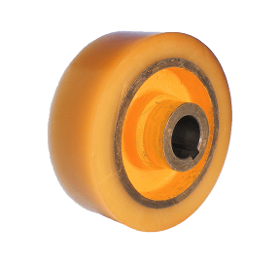

Heavy-duty castors with polyurethane wheel - wheel body made of special grey cast iron with ball bearing - tread made of molded polyurethane, approx. 95° shore A - heavy welded steel construction The strongest Torwegge housing series consist of a welded steel construction for maximum dynamic stresses. The swivel castor housings are equipped with sealed axial rib ball bearing an tapered roller bearing and thus particularly sensitive against surges and beats. The housing head is screwed and secured by a heavy center bolt. The material polyurethane (PU) has a high load capacity with low abrasion. It also features high chemical resistance. These properties make polyurethane suitable for almost any application. In addition, PU offers low rolling resistance.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Heavy-duty double castor with polyurethane wheel - wheel body made of special grey cast iron with ball bearing - tread made of molded polyurethane, approx. 95° shore A - heavy welded steel construction The strongest Torwegge housing series consist of a welded steel construction for maximum dynamic stresses. The swivel castor housings are equipped with sealed axial rib ball bearing an tapered roller bearing and thus particularly sensitive against surges and beats. The housing head is screwed and secured by a heavy center bolt. The material polyurethane (PU) has a high load capacity with low abrasion. It also features high chemical resistance. These properties make polyurethane suitable for almost any application. In addition, PU offers low rolling resistance.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 2 parts to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquids, drain water, sludge, food etc. (viscous media, pulverised media with fibre particles, plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (AISI 304) Stem Stainless steel 1.4305 (AISI 304) Function Electrical operated Pressure discharge bidirectional Stem Not rising Pressure range Please refer to the data sheet Temperature range • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy-coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Electric acting Pressure discharge One-sided Voltage 400V 3AC (24V DC, 230V AC on request) Pressure range Please refer to the table Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 2 parts to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquids, drain water, sludge, food etc. (viscous media, pulverised media with fibre particles, plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 9 and 11! Body GG-25 (grey cast iron), epoxy coated 120 … 180µm (heattreatment 190°C, 20min) Sealing • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (AISI 304) Stem Stainless steel 1.4305 (AISI 304) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge bidirectional Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the table Temperature range • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 8! Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge One-sided Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 Installation Only with vertical upwards actuator The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic double acting Pressure discharge bidirectional Pilot pressure 6bar (lower pressure on request) Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic double acting Pressure discharge One-sided Pilot pressure 6bar (lower pressure on request) Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 2 parts to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquids, drain water, sludge, food etc. (viscous media, pulverised media with fibre particles, plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (AISI 304) Stem Stainless steel 1.4305 (AISI 304) Lever Steel, lacquered Pressure discharge bidirectional Pressure range Please refer to the table Temperature range • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Lever Steel, lacquered Pressure discharge One-sided Stem Not rising Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 2 parts to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquids, drain water, sludge, food etc. (viscous media, pulverised media with fibre particles, plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (AISI 304) Stem Stainless steel 1.4305 (AISI 304) Hand wheel Steel, lacquered Pressure discharge bidirectional Stem Not rising Pressure range Please refer to the data sheet Temperature range • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Hand wheel Steel, lacquered Pressure discharge One-sided, two-sided on request Stem Not rising Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quoteResults for

Gray iron - Import exportNumber of results

22 ProductsCompany type