- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gaskets seals

Results for

Gaskets seals - Import export

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Using the materials mentioned, HEUTE+COMP. manufactures sealing elements and O-ring supports according to your specifications. PTFE support rings prevent high pressures from extruding O-rings into sealing gaps and damaging the rings as a result. Due to its cold flow characteristics and high degree of abrasion, pure PTFE is only conditionally suitable for sealing. Accordingly, a wide range of PTFE compounds have been developed to account for all involved parameters. Temperature Media influence Pressures Sealing gaps Assembly conditions Additionally for dynamic applications: Material and surface of the sliding counterpart Speed The technique used to process a material also influences its properties. For instance, a material filled with glass can be made gas-tight through special heat treatment. For this reason, our team offers consultancy early on during the development phase in order to select appropriate materials for your application.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Recycling made easy Our machine knives, of uncompromising quality, have been used for decades in recycling for tyre crushing. Even when separating rubber and spring steel, they have been proven in practice day by day. Whether shredder knives, spacers, scrapers or sealing gaskets, shredder teeth for multipleshaft shredders, rotary and stator knives for granulators or machine knives for guillotines Our complete range of products also covers the most demanding challenges in recycling.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MINEON HANDEL GMBH

Germany

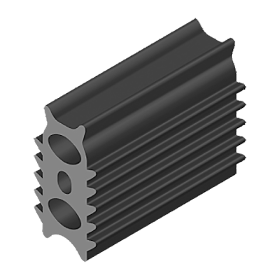

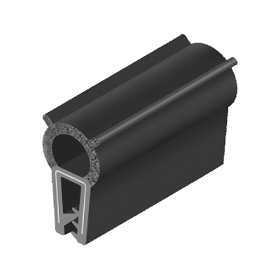

EPDM profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

MINEON HANDEL GMBH

Germany

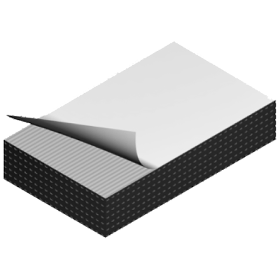

Sponge Foaming square sealing strip,with 3M tape,different sizes available.

Request for a quote

MINEON HANDEL GMBH

Germany

Sponge Foaming square sealing strip,with 3M tape,different sizes available.

Request for a quote

MINEON HANDEL GMBH

Germany

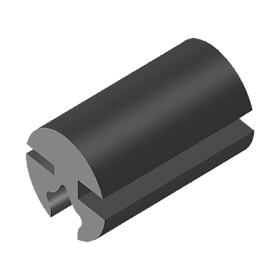

PVC profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

MINEON HANDEL GMBH

Germany

EPDM profile gasket with a good performance of aging resistance, water resistance, corrosion resistance.

Request for a quote

BEULCO GMBH & CO. KG

Germany

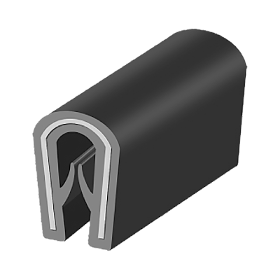

Plug-in connector for drinking water, water and gas. The material-friendly connecting technique enables that the pipe is only stressed as the relations of pression and torsion demand. Premature wear due to overstressing of material and subsequent troublescan be excluded. The metal clamping claw enables a torsion-free assembly by its positioning. The connector can easiliy be dismounted – all components can be reused without problems. For the application in the field of gas the connector has an additional insert pipe to stabilise the pipe. For the application in the field of drinking water the connector has the proven EPDM profile gasket which reliably seals minor damages on the surface. The plug-in connectors for the application in the fields of water and gas additionally have a special o-ring. The sealing and clamping functions are separated and independent which makes the connector extraordinarily safe.

Request for a quoteResults for

Gaskets seals - Import exportNumber of results

15 ProductsCompany type