- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fur blowing

Results for

Fur blowing - Import export

W. MÜLLER GMBH

Germany

Our extrusion heads for blow molding meet the highest demands in terms of precision, availability, performance and ease of use. And They ensure your safe and cost-efficient production.

Request for a quote

W. MÜLLER GMBH

Germany

The extremely space-saving design of our screen changer allows a lot of creative freedom, both with new machines and in the case of retrofitting, since the structure of the extruder platform only needs to be adjusted a little. The screen changer is installed instead of a connection piece and can be equipped with a hydraulic or electric drive. The simplest way, however, is to use a cordless screwdriver, which makes changing bits a quick and easy endeavor. Screen changers are available for all common throughputs.

Request for a quote

W. MÜLLER GMBH

Germany

The perfect combination of head and complete extrusion is the heart of every blow molding machine - tailor-made for your product and adaptable to every machine. Our platforms guarantee the greatest possible security and user-friendliness for users.

Request for a quote

W. MÜLLER GMBH

Germany

Even the best system needs a suitable controller. With our user-friendly and proven control concepts, you always have your production process in view and, above all, “under control” understandable, functional, reliable, clear and made for users. And Our wall thickness regulation saves raw materials and makes your production more sustainable!

Request for a quote

GSW SCHWABE AG

Germany

selfadherent blowout fitting through magnetic base amount of escaping air adjustable finely via a ball valve with position stable uniflextube for accurate positioning also suitable for cooling liquid

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

ideal for producing an air curtain or for drying extensive areas high blowing power at significantly reduced noise development flexible in user applications

Request for a quote

GSW SCHWABE AG

Germany

high blowing power at significantly reduced consumption of compressed air and lower noise development for every case of use the right passage ideal for blowing out punch parts Heat Resistance 90° C

Request for a quote

GSW SCHWABE AG

Germany

the good value for money choice for all standard applications high blowing power at significantly lower noise development flexible in user applications low air consumption Heat Resistance 90° C

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

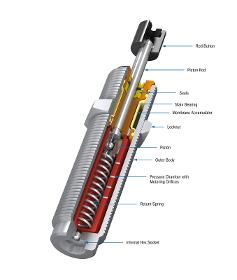

Energy capacity 56.5 Nm/cycle Stroke 18.7 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

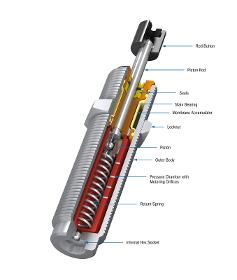

ACE STOSSDÄMPFER GMBH

Germany

Energy capacity 56.5 Nm/cycle Stroke 18.8 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Device for automatically blowing the adhering water off after passing through the pretreatment plant. The rotary blow-off zone is a device for blowing the adhesive water off workpieces that have been washed for the purposes of painting. It consists of a closed stainless steel sheet metal housing with forced ventilation and is employed immediately after the washing installation. In order to achieve more effective drying in the case of fissured surfaces, the blower nozzles are arranged on a rotary axis. The adhering water is blown off by the parts by air blown at high speed through the rotary blower nozzles. The effect of this is that no water droplets remain on the workpiece that could lead to slight marks in the paint film. Due to the varying blowing direction, the water is also blown out of problem zones and scooped parts in most cases. In order to be able to optimise the direction of the blower nozzle air jets, the nozzles have adjustable nozzle heads. The water that is blown off runs back into the pretreatment plant. The blowing air is extracted from the blowing tunnel via a return air duct with adjustable suction apertures.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp Bond Analyzer BLOW-SCAN is a detection systems which automatically detect blows and unbonded areas during the production of wood panels. It utilizes ultrasound and therefore is suitable for harsh production environment. Self-Calibration takes place in each panel gap. This compensates inuences raised from waste deposits and temperature variations. The models CONTI-SOUND and BLOW-SCAN are preferably installed in particleboard, MDF and OSB production lines. Changes of the panel properties are shown so the measurement can be used as an early warning System Features and Function Board thickness < 60 mm Density > 550 kg/m3 Detectable blow size > 28 mm Online calibration Automatic adjustment of sensor sensitivity Automatic recognition and compensation of dust load on sensors Automatic compensation of temperature drift Real-time data analysis Remote service

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Safety Relief Valves / Blow-Off Valves WITT safety relief valves (blow-off valves) protect against overpressure by venting excess gases from pipelines, gas receivers and other equipment. The spring-loaded, direct-acting safety relief valves (blow-off valves) are suitable for individual opening pressures from 5 mbar to 45 bar (approx. 0.07 to 1 435 psi). The compact size allows easy installation in any orientation. A dust cap protects the safety relief valves (blow-off valves) against dirt. WITT safety relief valves (blow-off valves) are available in brass or stainless steel, as a ventable version, and with or without condensation outlet.

Request for a quoteResults for

Fur blowing - Import exportNumber of results

14 ProductsCompany type