- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- food processing industry

Results for

Food processing industry - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

High polish stainless steel flanges are not just functional components in piping systems; they also offer a visually appealing finish that is smooth and reflective. This high polish, often achieved through a process called electropolishing, provides several benefits: Electropolishing Process. Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth and mirror-like finish. This process can also improve the corrosion resistance of the stainless steel by removing surface imperfections where corrosive agents could potentially take hold. Advantages of High Polish Finish Improved Corrosion Resistance: The smoother surface reduces the number of crevices where corrosion could start, thus enhancing the flange’s longevity. Easy Cleaning: High polish surfaces are easier to clean and sanitize, which is particularly beneficial in industries like food processing and pharmaceuticals.

Request for a quote

IGUS® GMBH

Germany

Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) iglidur® PRT slewing ring plain bearing data d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: 1 Aluminum, hard anodized 2 iglidur® J sliding elements

Request for a quote

CRAEMER GMBH

Germany

The 125 l large containers from Craemer are well-established in the entire food processing industry. Made from pure PE, the nestable 125 l large containers convince with their high wall thickness and heavy quality - ideal for use as storage containers for a variety of mixing goods or spices. The smooth inner and outer walls make the 125 l large containers particularly easy to clean. Characteristics: — Made from pure PE — High wall thickness, heavy quality — Nestable — Stackable with lid — Forklift accessible — Resistant to most common chemicals and cleaning agents — Easy to clean thanks to smooth inner and outer walls — Standard fitted with reinforcement bar Accessories: — Lid

Request for a quote

CRAEMER GMBH

Germany

The transport and stacking boxes are an indispensible part of smooth logistics in the food processing industry. They facilitate easy handling and reliable, hygienic transport processes. Characteristics: — Available in various sizes and versions (Stacking box: 25 l, 55 l, Transport box 40 l, 80 l) — Made from pure PE — High load bearing capacity and impact resistance — Nestable (40 l, 80 l) — Stackable (25 l, 50 l, 55 l) — Resistant to most common chemicals and cleaning agents — Easy to clean thanks to smooth inner and outer walls

Request for a quote

CRAEMER GMBH

Germany

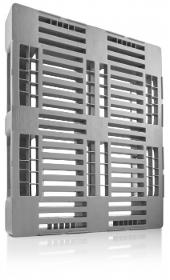

The H3 plastic pallet is the industrial-sized version of the H1 Euro pallet. This hygienic pallet is a proven choice primarily in the food and meat processing industry, however it is also suitable for transportation and storage of medium weight loads at temperatures down to -40°C in the non-food sector. The H3 plastic pallet is also available in a conductive version for use in the automotive, electrical and chemical industries as well as by their suppliers – to protect against electrostatic discharge (ESD). Characteristics: Available with 3 runners Ideal for medium weight loads High bending strength Ideal for transportation and bagged of sack goods or cardboard packaging Excellent cleaning properties Chamfered edges on both sides of all runners for optimal handling with fork lift trucks Options: Welded runners for a high standard of hygiene and smooth running on roller conveyors Rims: 7mm RFID transponder Palgrip® anti-slip coating under the runners ESD version

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Comprehensive Ex-protection for gas and dust environments PFLITSCH has many ATEX-certified cable glands for use in potentially explosive atmospheres – e.g. in the chemical, pharmaceutical and food industries, agriculture, wood processing and the metal industry. Your advantages: Areas of use G (Gas) and D (Dust) Equipment class II Explosion protection type e (increased safety) as well as d (pressure-tight encapsulation) in zones 22, 21, 2 and 1 The UNI Dicht Ex-cable gland versions in metal (brass and stainless steel) are available in sizes M10 to M80 and Pg 7 to Pg 48 as well as in plastic in sizes M16 to M50 and Pg 9 to Pg 36. blueglobe is ATEX-certified in sizes M8 to M85 in brass and stainless steel. TPE sealing inserts are used for operating temperatures between -40 °C and +115 °C, while silicone (LSR) inserts are used between -55 °C and +180 °C. The various Ex-certified EMC cable glands are particularly worthy of mention.

Request for a quote

CARBO-WELD SCHWEISSMATERIALIEN GMBH

Germany

Solid wire electrode suitable for joining and surfacing alloys of similar composition with up to 30% nickel as well as non-ferrous alloys and dissimilar steel grades. The deposit weld metal is highly resistant to seawater, typical applications include usage in shipbuilding, oil refineries, food processing industry, the engineering of general corrosion proof vessels and equipment.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Description - Delivery hose for conveying milk, by-products and generally liquid fatty foodstuffs - Normally used in dairies and food processing industries - Totally free from plasticizers and animal derivatives, reduces the risk of bacterial growth and contamination of the media conveyed - The high-strength hose structure makes it ideal for unloading operations of milk and milk products - The cover provides a good resistance to ageing and withstands accidental contact with animal and vegetable fats - Hose in accordance with EC 1935/2004 and 2023/2006/EC (GMP) and EC 1907/2006 (REACH) Tube - NBR, light color, food quality, odorless and tasteless, mirror-smooth, resistant to oils and fats - Compliance: FDA standards, BfR requirements, D.M 21/03/73 and RAL registration for food quality Reinforcement - Plies of synthetic textile - with and without embedded steel helix wire Cover - CR, blue, smooth, cloth finish, self-extinguishing, resistant to abrasion, ozone and weather

Request for a quote

WESTMARK GMBH

Germany

• with storage section • the self-adjusting spring-loaded mechanism holds the nutmeg against the blade with consistent force

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

Hitachi High-Technologies Europe GmbH is very pleased to introduce Hitachi Magnetrons, which are highly appraised for their high quality, high reliability, compact shape, light weight and low spurious radiation with up to 10kW Power, different type of cooling (water/forced air) and different outline dimensions. Hitachi Magnetrons are well-suited for various types of industries specifically in the fields of: Electronic Device Manufacturing Microwave Light Emission UV-Curing Industrial and Vacuum Drying Semiconductor Automotive Ceramic Industry Food Processing Dispensing and Coating Bonding & Lamination Applications Magnetrons' Line-up: 2M121A, 2M131, 2M130, 2M256, 2M251, 2M252, 2M304, 2M305 Magnetron 2M121A: Power (kW): 1.4 Frequency(MHz): 2,455 Cooling: Forced Air Outline Dimensions (mm): 127x104x109 Weight (kg): 1.4 Magnetron 2M130: Power (kW): 2.0 Frequency(MHz): 2,455 Cooling: Forced Air Outline Dimensions (mm): 128x116x122 Weight (kg): 2.3

Request for a quoteResults for

Food processing industry - Import exportNumber of results

15 Products