- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fine filters

Results for

Fine filters - Import export

GHM MESSTECHNIK GMBH

Germany

Filter inserts 5 to 300 Media temperature up to 52 C Nominal widths DN 4 to DN 20 Plastic PP/polyester materials

Request for a quote

HEBMÜLLER GMBH

Germany

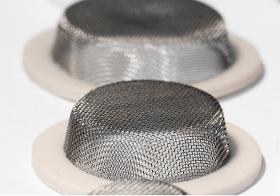

For strainers and fine filters in the drinking water sector, stainless steel mesh and plastics with drinking water approval (for example according to KTWBWGL, DVGWW270WRAS, NSF, ACS...) are used, mainly POM, POMGF30, PP, PPGF30, TPE.

Request for a quote

TROTEC GMBH

Germany

Economic acquisition, powerful performance values and simple handling – these characteristics are combined in a robust metal construction of the air cleaner TAC 1500 S that is suitable for use on construction sites. Its Monoventic regulator enables you to steplessly adjust the air volume precisely to your actual needs, and the flexible filter system allows for the use of variable filter combinations for every construction site situation. With the TAC 1500 S you can reliably filter coarse and fine dust or spray paint mist as well as concrete dust, fine sanding or plaster dust and highly dangerous quartz dusts or asbestos fibres. The filter frame can be flexibly equipped with one or two filter elements, for example a G4 filter or an additional F7 filter, so that in combination with the HEPA filter a two- or three-stage air purification process in accordance with dust class H can be achieved.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERKUTE MASCHINENBAU GMBH

Germany

Equipment New triple filtration design: coarse filter, fine filter, magnet Filterbag Usable area 730 x 520 mm with load capacity 100 kg Unit out of plastic (PE), no risk of corrosion. Extra easy to maintain - Control box contains the complete control- and pump device. Can be exchanged fast and easy at malfunction. Drain device make the exchange of the bio cleaner easier.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Equipment New triple filtration design: coarse filter, fine filter, magnet Filterbag Usable area 730 x 520 mm with load capacity 100 kg Unit out of plastic (PE), no risk of corrosion. Extra easy to maintain - Control box contains the complete control- and pump device. Can be exchanged fast and easy at malfunction. Drain device make the exchange of the bio cleaner easier.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Deisgn Y-strainer, body FBE-coated. Face to face EN 558-1 Row 1 Connection Flange DN25 … DN200, PN16 drilled, Flanges DN65 – PN16 will be delivered in 4-hole execution! Mounting position In horizontal pipes with below hanging top cover, observe to the flow direction! Pressure Range PN16 Temperature Range 0°C … +80°C Mesh Normal filter: Ø1,0mm, DN25 … DN65 Ø1,2mm, DN80 … DN200 Fine filter: Ø0,25mm Material Body: GGG-50, FBE-coated Cap: GGG-50, FBE-coated Filter: Stainless steel 1.4301 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quoteResults for

Fine filters - Import exportNumber of results

9 ProductsCompany type