- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filtering pumps

Results for

Filtering pumps - Import export

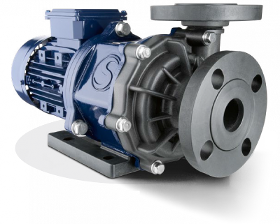

SONDERMANN PUMPEN + FILTER GMBH & CO. KG

Germany

without shaft seal streamlined housing made of PP or ETFE volume flow of up to 220 l/min delivery head of up to 14m.WG back pull-out

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

nickel plated brass

Request for a quote

F.E.S. GMBH

Germany

Automatic Precoat Filter are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Fully automatic operation Excellent filtration results Compact size Low maintenance requirements Full-flow filtration Dry cake discharge with minimal carryover of cutting fluid No fleece consumption Maximum lifespan of cutting fluid Operating Principle: The cleaned cutting fluid is supplied to the filter system pump (1) from the clean tank (2) of the processing machine. The contaminated cutting fluid is introduced into the dirt tank (3) of the cake filtration system through inlet channels or lifting stations. The internal processing of the system consists of four steps: “Cake Formation,” “Filtration,” “Regeneration,” and “Sludge Treatment.”

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Cutter Pumps The cutter pumps of the series SFC are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SFC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. The SFC pumps are equipped with the user-friendly 45 degree flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G 1/4. Volumetric delivery: up to 1700 l/min Delivery head: up to 45 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with double mechanical seal. This pump series is designed for horizontal installations next to a tank and are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60 HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SBC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. Volumetric delivery: up to 1400 l/min Delivery head: up to 34 m

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps Models TS12 to TS24 are suitable for CNC machine tools featuring coolant supply through the tool holder or driving spindle or equipped with internally cooled tool. These pumps are equipped with a peripheral impeller to achieve a compact high pressure unit. Series TS are suitable for filtered coolant only. To reduce pump pressure, models TS22 to TS24 are also available with an optional Y/YY (Dahlander) motor configuration for 4 pole operation at half speed. Volumetric delivery: up to 70 l/min Delivery head: up to 95 m Please contact us for delivery quantity

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Specially designed for industrial hydraulic installations, the STAUFF Offline Filters are available in single or multiple housing configurations. The Offline Filter Units can easily be mounted to new and existing hydraulic installations. By means of an integrated motor/pump unit and an Offline Filter, the oil is pumped from the reservoir through the filter unit and after filtering the oil is then returned to the tank. Motor/Pump Unit ▪ Available in different configurations ▪ Air driven motor Clogging Indicator (available as an option) ▪ Visual clogging indicator ▪ With water sensor Filter Elements ▪ Filter elements of SRM series Construction ▪ Offline filters with integrated motor/pump unit ▪ Heated offline filter unit Nominal Flow Rate ▪ Max. 4,2 l/min / 1.2 US GPM Max. System Volume ▪ Up to 2.700 l / 713 gal Water holding capacity ▪ Up to 2.280 ml / 80 oz. Materials ▪ Anodizied Aluminium

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Systems Units are characterised by their extremely efficient filter elements which are rated to 0,5 micron. Specially designed for industrial hydraulic installations the STAUFF Offline Filters are available in single or double length configurations. The Offline Filter Units can easily be mounted to new and existing hydraulic installations. By means of an integrated motor/pump unit and an Offline Filter, the oil is pumped from the reservoir through the filter unit and after filtering the oil is then returned to the tank. Motor/Pump Units ▪ Different configurations available ▪ Air driven motors Clogging Indicators (available as an option) ▪ Visual clogging indicator Filter Elements ▪ Filter elements of SRM series Pre-Filter Elemets ▪ Spin-On filter elements of SF67 series Construction ▪ Offline filter with integrated motor/pump unit ▪ Offline filter units with up to four filter housings in single or double length configurations Nominal Flow Rate ▪ 2,1 ... 17 l/min / .55...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Offline Filter Units can be applied to every imaginable industrial application where hydraulic or lubrication systems are present. An integrated motor/pump unit draws fluid out of the tank, filters it and pumps clean oil back into the system. Offline Filter Units can continue to work even when the main system is not in use. Motor/Pump Unit ▪ Available in different configurations ▪ Air driven motors Clogging Indicator (available as an option) ▪ Visual clogging indicator Micro Filtration Elements ▪ Micro filter elements of SRM series Construction ▪ Offline filter with integrated motor/pump unit ▪ Offline filter units with up to four filter housings in single or double length configurations Nominal Flow Rate ▪ 2,1 ... 17 l/min / .55 ... 4.5 US GPM Max. System Volume ▪ Up to 10.800 l / 2.853 gal Port Connection ▪ G3/8, G1/2, G3/4 and 18 L Materials ▪ Anodised Aluminium Media Compatibility ▪ Mineral and lubrication oils, other fluids on request

Request for a quoteResults for

Filtering pumps - Import exportNumber of results

12 ProductsCompany type