- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- film production

Results for

Film production - Import export

PETROPLAST GMBH

Germany

True versatility for the food and non-food sectors: Mylar ® PET packaging films We work with a broad range of Mylar ® PET packaging films. Mylar ® OL, Mylar ® OLAF, Mylar ® RL and Mylar ® 850 are particularly popular with our customers thanks to their many different uses for food and non-food items. Mylar ® PET packaging films are characterised by their high levels of resistance to heat and cold as well as their flexible ability to seal with many polar materials. We will gladly advise you on the best packaging film for your product. Mylar ® PET packaging films – the facts: Mylar ® OL Mylar ® RL Mylar ® 850

Request for a quote

PETROPLAST GMBH

Germany

Laminated Film We work with laminated film characterised by its outstanding barrier properties and highly flexible sealability. Laminated film is used in the food sector, for example for packaging ready meals, fresh produce or oily food. Are you looking for the right laminated film for your product? Let us find it together. Laminated film – the facts: Laminated film for food packaging, e.g. for ready meals and fresh produce as well as oily food. Laminated film thickness: 54–67 microns, further thicknesses and laminate types on request Sealable at 140–180 °C against A-PET, C-PET, PP, PS, PE and PVC, as well as self-sealing Laminated film suitable for pasteurisation Excellent barrier properties (e.g. through PE-EVOH-PE) Available with anti-fog treatment

Request for a quote

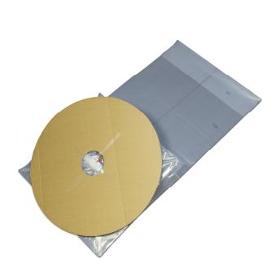

EMPAC GMBH

Germany

Lining made of PE or Aluminium, EVOH, PA etc. in combination with PE as well as electrostatically conductive foils for rigid or flexible Intermediate Bulk Container. Customer requirements and fields of application determine the material’s strength. The product range includes liner with filling and /or discharge spouts, simple liner (welded at the bottom and open at the top) as well as formstable liner with a grid, particles which allows an improved product flow. This liner can be produced as strengthened PE-Liner as well as Aluminium-combined liner. An ingenious system ensures that the layer made of Aluminium will not be strained and therefore still displays a barrier which offers a 100% security. Additionally, Pacliners are produced with a fixed cardboard at the bottom on request. EMPAC has also developed a special liner for the filling of EPS (expanded Polystyrol) whose special film recipe prevents a product-gas escape.

Request for a quote

POLYPLAST MÜLLER GMBH

Germany

Antiblock properties are required for film and flexible packaging production. Antiblock additives enable the reduction of adhesion (also known as “blocking”) between 2 film layers, which results in much better handling both during production and during later use of the product.

Request for a quote

POLYPLAST MÜLLER GMBH

Germany

White masterbatch is primarily used for the production of films, blown bottles, injection molded products and profile extrusions. Our high quality range of concentrates – such as for paper coatings – includes UV resistant solutions for silage stretch film as well as pigment filler mixes for standard applications. With or without fillers – or with additional agents like UV or thermo stabilizers – Polyplast Müller white concentrates are convincing due to their attractive price/performance ratio and their wide range of possible applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quoteResults for

Film production - Import exportNumber of results

8 ProductsCompany type