- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- exhaust systems

Results for

Exhaust systems - Import export

THERMA THERMOFÜHLER GMBH

Germany

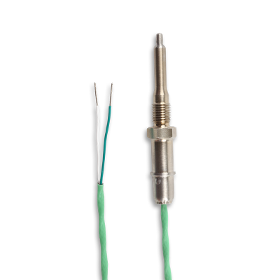

The sheathing thermocouple from Therma is perfect for reliable and fail-safe temperature measurement in the exhaust gas system. It excels with its simple structure. By selecting double-walled sheathing material made of Nimonic75, this thermocouple is well prepared for corrosion influences and vibrations along with extremely high temperatures. Furthermore, assembly with a compression-type fitting lets you decide the installation length onsite. Sheathed thermocouples NiCr-Ni, Type “K”, Class 1

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This sensor for measuring exhaust gases was developed together with a Formula 1 team. The goal was to achieve the greatest possible reliability during the race. The sensor was designed so that it can withstand a maximum of vibrations and extreme temperatures while being made in a highly compact construction at the same time. The special feature is the connection lead. It is not made from the usual mineral-insulated stainless steel sheathed line, which is too rigid and which tends to vibration fractures. Instead, the line is made of stranded conductors with PTFE insulation and an additional heat shield so it can be easily and flexibly adapted to the environment. The sensor is being used with exceeding success by professional teams in long distance races, American race series and the domestic DTM. The benefits: Highly vibration-proof Very robust High temperature resistance (up to 1,200 °C) Individual plug assembly possible Can be individually adapted

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This plug-in sheathing thermocouple is recommended for measuring the temperature in the exhaust gas flow. It is genuinely multipurpose, mounting with the cap nut means the thermocouple does not need to be rotated, which simplifies installation and fast replacement. In addition, it has “motor sports genes” such as vibration resistance, fast response time and high temperature resistance. The benefits: Vibration-proof Fast response time High temperature resistance (up to 1,200 °C) Various installation lengths can be supplied With cap nut Sheathed thermocouple NiCr-Ni, Type “K”, Class 1

Request for a quote

GTC GMBH

Germany

Everyone knows that the key to a long and and troubleless operation of the engine is the use of high-quality motor oils and lubricants that meet the requirements of the vehicle manufacturer and its timely replacement. Buying oil and technical liquids from us, you can be confident in the quality of purchased products; then, our company is the official partner of such leading brands as CASTROL, MOTUL, VENOL, which is confirmed by the corresponding certificates. Our experts will help you choose lubricants, and prices will surprise even the most discerning buyer.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Bentley-Harris® Textalu 1202 is an insulative fiberglass sleeving with a heavy aluminum coating designed to protect components in high temperature areas. It provides superior insulation to components that must maintain stable temperatures to assure performance efficiency. Textalu 1202 is used on wire harnesses, sensor control wiring and cable assemblies in close proximity to engines and exhaust systems. Due to its elastic structure, Textalu 1202 conforms well to the variable profiles of the components it protects. Its braided construction allows good flexibility in temperatures as low as -50°C. The infra-red emissivity rating of Textalu 1202 heavy aluminum coating, combined with its fiberglass braid, ensures temperature stability inside the Textalu sleeving despite frequent external temperature fluctuations due to radiant heat.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pre-treatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pretreatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

For its exhaust gas purification systems, Venjakob Umwelttechnik offers heat exchanger systems for utilizing the waste heat. These are characterized by: We build complete heat exchanger systems for heating water, steam, air, and gas or heat transfer fluid. The residual or excess energy contained in the clean gases of the Venjakob exhaust air cleaning systems often has sufficient potential to effectively support the actual production process, the building heater or other energy consumers. Whether as an individual system for heat transfer fluid, warm and hot water, hot air, and vapor, or combined as a downstream system solution for an exhaust air purification system - the planning, construction and production of the plant are done on an individual basis.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The regenerative thermal oxidizer from Venjakob Umwelttechnik with its low consumption of primary energy is particulary well suited to the removal of low to medium concentrations of solvend based pollutants (VOC). This machine is characterized by: The regenerative thermal oxidizer (RTO for short) embodies the state of the art technology for cleaning organic pollutants from exhaust gases (including VOCs). The systems ordinarily feature three alternately supplied heat exchanger chambers equipped with ceramic honeycombs. This material is suitable for absorbing, storing, and transferring very high amounts of heat. This allows a heat exchanger efficiency of over 95% to be achieved, so that the process temperature above 800 °C, which is required for the pollutant conversion, can be reached with a minimum of additional energy. Consequently, depending on the combustion heat of the pollutants to be cleaned, autothermal operation can be accomplished for most applications without the need for additional fuel. With careful planning, the excess heat of combustion can be effectively utilized so that the overall system can be viewed as an energy source rather than as an energy consumer. We can offer a variety of special solutions depending on the application:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The adsorption system (AD) from Venjakob Umwelttechnik serves to concentrate exhaust air flows containing low concentrations of pollutants, and is particularly suitable for removing extremely low to medium concentrations of solvent-based pollutants (VOCs). This machine is characterized by: During the adsorption process, the pollutants are physically retained on the surface of a solid material (e.g. activated carbon, zeolite). The pollutants are then removed /desorbed from the zeolite by means of a small, hot stream of air. Afterwards, the flow of exhaust air from the desorption process is cleaned by means of an exhaust air cleaning system (TI, RTO, CTO). By reducing the volume and by increasing the concentration, the operating costs of the downstream exhaust gas purification system can be kept very low and make autothermal operation possible among other things The rotor is mounted vertically on a shaft with bearing and rotated slowly in the air flow. During rotation, the adsorption and desorption take place simultaneously in separate chambers with cooling on a hydrophobic (water-repellent) incombustible zeolite material. For tough applications, versions can be provided with a removable wear layer and / or higher temperatures of up to 300 ° C for desorption. Two containers are operated alternately. While one of the containers is adsorbing, the other container can be desorbed The adsorption process can be used for smoothing pollutant concentration peaks. If pollutant peaks occur during a process that could lead to a potentially explosive mixture (> 25% lower explosion limit), they cannot be introduced into an incinerator. However, the pollutants may be temporarily stored in an adsorber and then be released during the desorption phase. In certain situations, the installation of an additional fixed bed adsorber (molecular sieve) may further enhance the process (safety, operating costs).

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The flow tester CETATEST 915 is used for flow testing with compressed air. It includes a measuring system consisting of laminar flow element (LFE) and differential pressure sensor In the direct test method the air, provided by the internal pressure regulator, flows through the measuring section before it enters the test part.In the indirect method, the measuring section is located in the outlet flow of the test part. Due to the special design of the measuring section a laminar ow is generated. The resulting pressure difference is directly proportional to the volume flow. With the optional electronic pressure regulator and four calibrations for up to four test pressures the application range is substantially expanded. Special versions: The CETATEST 915-G is a fully automatic flowmeter for the detection of leaking parts. Typical applications: 915: Testing of valves, vehicle exhaust systems, pipes, membranes, 915 G: Gas appliance industry, after-work jobs in the automotive industry

Request for a quoteResults for

Exhaust systems - Import exportNumber of results

12 ProductsCompany type