- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die stamping

Results for

Die stamping - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stampings (and stamped parts) are versatile and you find them in a wide range of applications for many different industries. Lesjöfors delivers stamped parts from our standard program as well as customized solutions.

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Part length: customer specific after consultation Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Meeting the closest tolerances Specialities Partial machining Stamping Thread cutting or rolling Fully automated mating with other parts Mounting and component manufacturing Processing of painted wires Rapid prototyping

Request for a quote

A + H THOMAS GMBH + CO. KG

Germany

We manufacture punched parts made of aluminum, stainless steel or plastic according to your specifications using high-quality punching tools on our modern punching machines. We can mill or laser smaller quantities or sample parts made of plastic or non-ferrous metals on our CNC machining center or our CO2 laser systems and label them as required.

Request for a quote

ROHRE-KETTERER GMBH

Germany

Stamping of especially thin-walled tubes with high demands on precision and a burr-free surface is one of our specialities. We are stamping with full and half automated stamping units and can produce any stamping geometry in one clamping withoud deforming the parts.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories of panel.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the accessories used in electronic panel control,after processing for a variety of color surface treatment.

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

BORNEMANN GMBH

Germany

Machine stamping presses with peg or threaded hole for mounting onto a press. For standard stamping presses we also offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference here. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination.

Request for a quote

BORNEMANN GMBH

Germany

Stamp mouldings for embossed or recessed stamping of aluminium or stainless steel sheets for the car industry. We produce the stamp mouldings in accordance with your data in soft or hard condition. Thanks to the high-quality structures, the movement between top and bottom dies is precisely coordinated. The design is based on your drawings or data.

Request for a quote

BORNEMANN GMBH

Germany

Sheet stamping dies, also called double stamping dies, with top and bottom parts for embossed or recessed stamping of sheets. For the production of these stamping dies, the strength of the sheet to the stamped is enormously significant. The movement between top and bottom stamp is designed according to these requirements. The parts are hardened in line with the purpose and delivered ready for use. We adopt the data from your drawings or drafts for production.

Request for a quote

BORNEMANN GMBH

Germany

Hot stamp dies or brass dies for labelling leather, wood, synthetics or paper. Labelling is carried out with or without colour film while feeding heat and gives the product an exclusive design. When making the brass die, we are guided by your requirements.

Request for a quote

BORNEMANN GMBH

Germany

Automatically switching stamping presses are automatically advanced with an embossing stroke. Automatically switching are five points as a rule, the other points are switched manually.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The effective protection against self loosening and unscrewing. The "SK" Serrated Locking Washer prevents self-loosening of screwed joints. Damage to the bearing surfaces and consequent variations in the tightening torques, as they occur in threadlockers with teeth are avoided with lock washers through the special geometrical shape of the locking edges. shape S (small) shape M (middle) shape B (wide) shape Z (for screws with cylindrical head shape) shape K (for electrical contacts)

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Tool making & construction: The key to success We know the different industry-specific requirements for stamped parts and parts suppliers. Therefore, our day-to-day work includes very demanding tasks, which we overcome speedily and process reliably. Our spectrum of services for tool construction includes: 3D-CAD/CAM construction and programming (solid works, Peps, HSMworks) Wire-cut EDM (also contract manufacture) with workpiece sizes up to max. 600x400x350 mm Drilling erosion (start hole shooting) with workpiece sizes up to max. 250x350x300 mm Milling technology with workpiece sizes up to max. 650x500x500 mm Turning technology with workpiece sizes up to max. dm 210 x 1000 mm Flat grinding with workpiece sizes up to max. 600x300x375 mm and more…. Even complicated customer requirements are never a problem for us, but are instead a welcome challenge.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

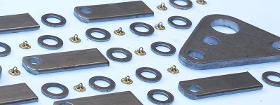

PIERON GMBH

Germany

Dimensions Depending on the required stamp power (material strength, material thickness, and part shape) Material All spring materials in soft and hard condition as well as quality steels with lower strengths and aluminum alloy and also special alloy Stainless steel up to 1900 N/m² Rubber-coated strip material Hardening Through external services Coating Fully or partly coated strip material In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Fully automated manufacturing of components and mounting Fully automated welding Contact springs with contact rivet Bushes clinched, welded, and open Special processing like thread cutting, screw mounting, and rivets feasible Special packaging in blister pack, trays or magazines Rapid prototyping

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

As a competent industrial partner, we produce stamped, bent-wire and formed components from stainless steel, non-ferrous metals and regular steel in a consistent quality. Dependability and flexibility characterize our performance. Our experience and technical know-how enable fast response and economical pricing. Benefit from the experience our staff have gathered with these products. We can competently process small as well as large orders. Possible material thicknesses: 0.5 to 4.5 mm. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The contact lock washer to NFE 25-511 and SN 70093 with grooved surface provides the designer the ability to secure wobble-prone screw effectively. It is particularly suitable for use on slot fasteners, dynamic cross-loaded to the screw connections and applications that require high biasing forces. Operational: The contact wheel ensures positively spring and a form-fitting locking. Form S = narrow - for small headrests Form M = average - for normal headrests Form B = wide - for large pressure transmission surfaces and slot fasteners Form K = serrated - for electrically conductive connections with contact teeth (SN 70093)

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The effective protection against self loosening and unscrewing. The "NSK" LOCK WASHER is the improved design of the "SK" LOCK WASHER. It also prevents self-loosening of screwed joints and damage to the bearing surfaces and consequent variations in the tightening torques, as they occur in threadlockers with teeth are avoided with lock washers through the special geometrical shape of the locking edges even better than the proven "SK" LOCK WASHER.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

We are not dictated to by standards. If at all, our sole and uncompromising standard is to produce the best possible knife for your task. We are your experts in this.

Request for a quote

ALVA LEATHER GMBH

Germany

These leathers are produced based on our requirements on a regular basis. Our regular leathers are defined as corrected leathers as well.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

Technical plastic : Polyethylene (Short : PE) Product name Polyethylene (PE or sub groups like PE-HD, PE-LD, PE-HMW, PE-UHMW, PE 300, PE 500, PE 1000 or RCH 1000 and many more) Delivery form Sheets, cuts, milled products, base profiles Specification Polyethylene - technical plastic Polyethylene ( Short: PE ) is a technical plastic that can be processed easil. It has a density of about 0,95g/cm³ and with that it's the second least weighing plastic of all technical plastics and just because of that it offers a very interesting price. The moisture absorbtion of PE is about 0,0 %. The material is really good against lyes and acids , has a self-lubricating effect and is easy to mill ( cut, milling, lathe, water jet cutting and welding ). Furthermore it is a great material for abrasive fraught parts in e.g. machine engineering ( PE UHMW ), as inlay for bulk containers or as a cutting boards in the food industry or households. We would like to advise you which kind of PE RG ist the...

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

– up-to-date methods for ideal results We manufacture every part variably and precisely using up-to-date techniques. Our objective: to put your requirements in the nutshell. With our modern die-cutting systems we satisfy your needs and produce i.a. Precision stamping parts Bending parts Drawing parts Contacts Complex lead frames Our automatic cutting presses and eccentric presses dispose a press capacity from 250 kN to 2800 kN. With the assistance of our actual manufacturing site we nearly handle every kind of requested material. For instance: Copper Cu Bronze CuSn Brass CuZn Steel DD, DC Coated strip material Chrome-nickel-steel X10CrNi / 1.4310 with a stability from 600 to 2.200 N/mm² Stainless steel X5CrNi / 1.4301 Aluminium AL The material can be already galvanised, tin-plated, silver-plated or gold-plated. Just tell us what you need. We come along with the solution.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

We accept responsibility for the whole process of production. On the one hand, we set outsourced items or provided parts like Press-in bolts Clinch studs Ball studs Weld screws Weld nuts into complex assembly groups. On the other hand, we offer downstream services like Thread cutting Slide grinding Defatting Special packing operations (in trays / blister packaging, wound on spool, packed in layers) Your needs and wishes always have priority and always will have. For that purpose we cooperate with reliable suppliers, who take charge of downstream surface treatment like: Galvanising Chrome-plating KTL-coating Silver-plating Hardening Press tempering Powder coating On your wish we guarantee particle purity and silicone-free packing.

Request for a quoteResults for

Die stamping - Import exportNumber of results

30 ProductsCompany type

Category

- Sheet metals - stamping (5)

- Stamping - steels and metals (4)

- Metal straightening machines (2)

- Stamping - machine tools (1)

- Sensors (1)

- Alarms - security devices (1)

- Cables - accessories (1)

- Frames and mountings, photograph (1)

- Import-export - steels and metals (1)

- Knives, industrial (1)

- Leather - Raw Materials (1)

- Pipes, bent - ferrous metal (1)

- Wire springs (1)