- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coupling flanges

Results for

Coupling flanges - Import export

IGUS® GMBH

Germany

The new direct-current motors with worm gear enable quiet and economically efficient operation with drylin® lead screw units. The worm wheel has a spline to which the drive pin of the linear unit is connected. As a result, a motor flange and coupling are unnecessary and, this taken in conjunction with the motor adapter angled by 90°, the structure of the linear module is very compact. Thanks to the integrated magnetic rotary encoder (2-channel hall), the new DC motors are suitable for positioning. - Space-saving and compact design - Easy to fit - Quiet operation - Rotary position encoder included - Suitable for: SLW-BB, SAW, ZLW

Request for a quote

R+L HYDRAULICS GMBH

Germany

Minimum mounting length Blind assembly No maintenance Heat resistant up to 120°C High torsional stiffness

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

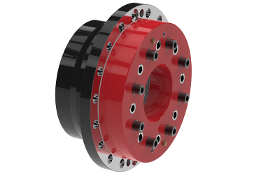

Advantages Salient features and advantages of the RCT coupling: ➜ Sub critical operation through high torsional stiffness ➜ Vibration and torque shock damping through flexible rubber coating ➜ High torque transmission capacity, fail-safe ➜ Ambient temperatures from -25 °C to +100 °C ➜ Compact, robust, maintenance-free ➜ Ease of assembly thanks to the plug-in axial design ➜ Backlash-free shaft-hub connection ➜ Compensation of axial, radial and angular displacements ➜ Multiple spline options for the connection to the pump shaft ➜ Bellhousing flanges for almost any mounting situation

Request for a quote

TAS SCHÄFER GMBH

Germany

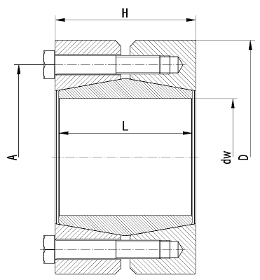

The main function of a hydraulic lange coupling (hereinafter called FKH) is the safe connection of two shafts. For example, between a drive shaft and a transmission shaft. The FKH produces a rigid and backlash-free connection between the shafts. This connection is mainly used to transmit torque, but can also absorb bending moments. The FKH is located in the power low. It is installed by sliding the FKH onto the shaft and the subsequent tightening of the hydraulic system. By using conical surfaces the inner diameter reduces and the radial pressure is built up. After clamping the FKH will be locked mechanically and the hydraulic pressure will be removed. Due to this simple approach, the FKH is suitable for repetitive clamping operations. Advantages of the FKH: • high transmittable torque and bending moments (high friction) • application-speciic design/customization • easy mounting and adjustment because of clearance it • relatively low pressure (closed system) • very rapid...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAS SCHÄFER GMBH

Germany

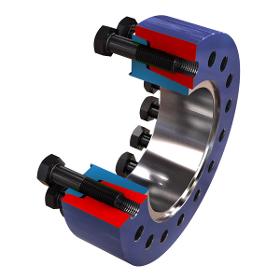

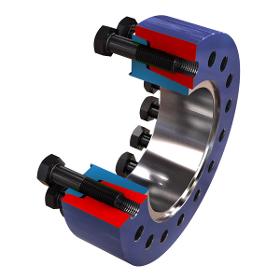

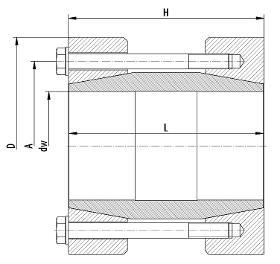

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The clamping tool is placed onto the front of one coupling half and is used to clamp the pressure ring of the coupling. After fixing the coupling half, the tool is removed and can be used for further couplings of the same nominal size. The clamping tool is placed onto the front of one coupling half and is used to clamp the pressure ring of the coupling. After fixing the coupling half, the tool is removed and can be used for further couplings of the same nominal size.

Request for a quote

TAS SCHÄFER GMBH

Germany

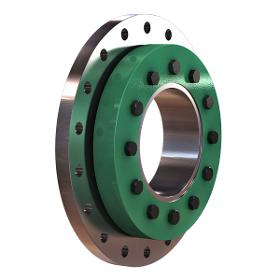

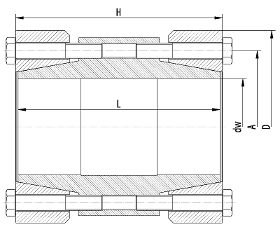

Use full screen mode The main function of the rigid flange coupling (FKE) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used pressure ring generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. It can also be transmitted axial forces and bending moments. The shrink connection do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the pressure ring. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. The clamping is done manually by means of screwing tools. Optionally with a hydraulic clamping tool. To achieve proper...

Request for a quote

TAS SCHÄFER GMBH

Germany

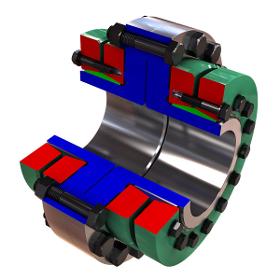

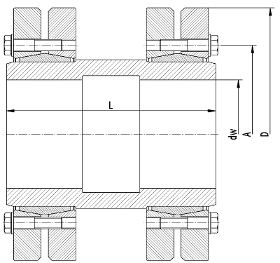

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quoteResults for

Coupling flanges - Import exportNumber of results

16 Products