- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- corrosion resistant metals

Results for

Corrosion resistant metals - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

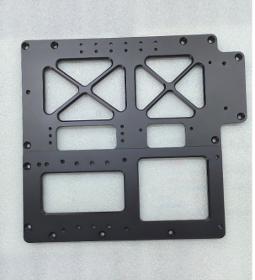

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume: 660 L Nominal loading capacity: 270 Kg + manufactured by compact injection moulding process from high molecular weight, high-density polyethylene (HDPE) in accordance with the test + regulations of DIN EN 840 and RAL GZ 951/1 + resistant to frost, heat and chemicals; stabilised against UV radiation + standard emptying options of either DIN or comb-lifting device; optionally with Ochsner handles of zinc-plated steel + quiet-running, full rubber heavy-duty castors of 200 mm diameter, 360° swivel range + wheel stop brake system (dual stop) as standard feature; alternatively available with central braking system + zinc-plated, corrosion-resistant metal parts + frontal comb is equipped with a chipnest to accommodate data carriers in accordance with DIN 30745 and RAL GZ 951/1 + optimised for high stacking with strong stacking ribs + drain plug in the bottom facilitates cleaning + available colours: grey, blue, brown and green

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume 1100 L Nominal loading capacity 144 Kg + manufactured in accordance with the regulations of DIN EN 840 (Parts 3, 5 and 6) and RAL GZ 951/1 + are suitable for both DIN and comb-lifting devices (form A in accordance with EN 840-3) + easy-to-move, spring-supported sliding lid, lockable in three positions + high-quality high-density polyethylene (HDPE) + UV stabilised, resistant to frost, heat and chemicals + 200 mm diameter quiet-running, solid rubber heavy-duty castors, 360° swivel range + available with wheel stop/double stop or central braking system + corrosion-resistant metal parts + the lid is attached to the body with high-strength polyamide hinges. Corrosion-protected metal springs keep the lid closed + can be easily moved from all sides by using the four lateral handles on the body + the waste bin features a standard water drain (2 inch water drainage hole) + available in all usual colours and combinations (e.g. grey, blue, brown or green)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Material and design in compliance with section 7.3 (Tubing Installation) of the Norwegian offshore standard Norsok Z-010 (Revision 3, published in October 2000 ), API RP 552 and NACE SP 0108-2008 (section 13) Clamp body made of flame-retardant PP-V0 plastic material (tested and V0 classified according to UL 94) Integrated anti-corrosion elastomer strips avoid the accumulation of seawater between clamp body and pipe Drainage channels aid the dispersal of seawater (self-draining) ACT Mounting Hardware is made of Stainless Steel V4A (Material Code: W55) with enhanced corrosion resistance by practically excluding metallic and non-metallic impurities during production, processing and handling ▪ Suitable for continuous exposure to temperatures from -25 °C to +80 °C (from -13 °F to +176 °F) ▪ High UV stability of the clamp body material; resistant against seawater, rain and oil ▪ To be used in sub-sea and top-side environments; alleviating the requirement for two different...

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume: 770 L Nominal loading capacity: 310 Kg + from high-quality, high-density polyethylene (HDPE), manufactured by compact injection moulding process + complies with the regulations of DIN EN 840 and RAL GZ 951/1 + tested, monitored and marked with the GS symbol (Tested Safety) in accordance with the German Product Safety Act. + resistant to UV rays, frost, heat and chemicals + fits all standard lifting devices (DIN and comb-lifting); available with Ochsner handles from zinc-plated steel + equipped with quiet-running, solid rubber heavy-duty castors, 200 mm diameter, 360° swivel range, wheel stop as standard feature; also available with central braking system + corrosion-resistant, zinc-plated metal parts + available colours: grey, blue, brown and green, additional colours upon request; all colour pigments used are colour-fast + with chipnest as standard, to accommodate transponders/data carriers in accordance with DIN 30745 and RAL GZ 951/1

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Corrosion resistant metals - Import exportNumber of results

6 ProductsCompany type