- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping systems

Results for

Clamping systems - Import export

GSW SCHWABE AG

Germany

Paper Unwinder with a mechanical drag brake and conical clamping system, available in different sizes and versions for all types of coil reels and for all material widths Paper Recoiler, for all types of coil reels and for all material widths, with air motor or with electromotor

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides its own systems Freek also manufactures original Rosemount-systems that can also be used as "Husky-replacement heater" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Both systems can be supplied with MicroCoils in "Rosemount style" (Ø 1,4 mm) as well as MicroCoils in "Freek style" (1,3 x 2,3 mm).

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-FIT150 series are the ideal tool for deburring on automatic deburring machines and are particularly suitable for machining larger series. Various deburring machines are equipped with right- and left-rotating deburring discs. For this purpose we offer you our FAPI-QUICK-FIT ADAPTER! The combination of the quick-clamping system and our FAPI-QUICK-FIT ADAPTER also enables simple mounting and positioning of the deburring discs FAPI-FIT150 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

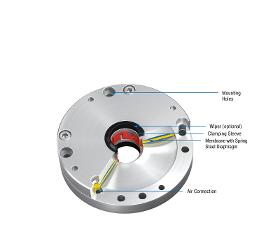

Pneumatic Rotational Clamping Holding torque 76 Nm Direct clamping on the shaft: Rotation motions are prevented by the ACE models LOCKED R. Their clamping elements are available for shaft diameters of 50 to 340 mm and ensure maximum holding forces. The clamp is immediately applied by the diaphragm and spring-plate system when pressure is lost. Pneumatic quick-switch valves reduce the reaction times. The costs are low in comparison with hydraulic clamping systems. Their performance is, however, achieved or exceeded despite the compact and easy to assemble design. Special versions for YRT bearings as well as active clamping elements are additionally available. ACE recommends the use of the optional shaft flange as wear protection. The clamping force can be increased considerably by the use of the additional air function.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Especially for high-cavity PET plastic injection moulding there are various industry standards of clamp-band nozzle heaters available. Most common are the Axial Clamp-Band Heater and the Two-screw Clamp-Band Heater. Our HotCoil cable heaters with clamp band represent a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides their own clamp-band designs Freek also manufactures original Rosemount clamp-bands that can be used as "Husky-replacement heaters" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Freek has all the various industry standards for clamp-band nozzle heaters in Ø19,05 and Ø22,40 in their assortment, too. HotCoil minitubular heaters with clamp band are a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

REVOLVING CROSS CUT SAW WITH NC PROGRAMMING SYSTEM GAMA 65 K3 Fully automatic circular saw for positioning and controlling via touchscreen with length measuring system EXENSO COMFORT (Pusher system) Application Length stop system (pusher operation), revolving table and sawblade inclination via servo - motor for positioning ( cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Technical Equipment : - Motor rating 8,1 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Sawblade height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT – sawblade 650 x 30 x T 54 - Dust extraction spigot 125 / 80 mm - Revolving table 20° - 160° - Horizontal material clamping system, right - left - pneumatische Kappvorrichtung über ZweihandSteuerung/vollautomatisch

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor 224 kW T4i for driving and drilling Drill rig with rubberised steel trackundercarriage, stabilisers Spacious, air-conditioned and heated cabin, Comfortable seat, joysticks, 12" Touch-Screen Fully galvanised rod box for 288 m of drill rods Fully automatic rod exchange system Semi-automatic clamp and break-away facility Anchoring system Powerful 650 l/min HP Bentonite pump on-board the rig Bore data log – telemetry data transfer Bore automatics, percussive hammer, high pressurecleaner, wireless remote control Mixing unit MA07 D (electric version optional)

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor T4i for driving and drilling, 126 kW Drill rig with rubber track undercarriage, stabilisers Spacious cabin, comfortable seat, joysticks, LCD display Fully galvanised rod box Semi-automatic rod exchange system Semi-automatic clamp and break-away facility Anchoring system with drilling fluid collecting tray Powerful HP Bentonite pump on board the rig Bore data log – Telemetry data transfer Optional: automatic / fully automatic drilling, high pressure cleaner, wireless remote control, rubberised steel track undercarriage

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor T4i for driving and drilling, 126 kW Drill rig with rubber track undercarriage, stabilisers spacious cabin, comfortable seat, joysticks, graphical display Bore automatics semi-automatic rod exchange system semi-automatic clamp and break-away facility Anchoring system with drilling fluid collecting tray powerful HP Bentonite pump on board the rig Bore data log –Telemetry data transfer optional:fully automatic drilling, wireless remote control, air conditioning

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor T4i for driving and drilling, 123 kW Drill rig with rubber track undercarriage, stabilisers Spacious cabin, comfortable seat, joysticks, LCD display Fully galvanised rod box Semi-automatic rod exchange system Semi-automatic clamp and break-away facility Anchoring system with drilling fluid collecting tray Powerful HP Bentonite pump on board the rig Bore data log – telemetry data transfer Optional: Bore automatics, percussive hammer, high pressure cleaner, wireless remote control, rubberised steel track undercarriage

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor T4i for driving and drilling, 119 kW Drill rig with rubber track undercarriage, stabilisers Spacious cabin, comfortable seat,joysticks, LCD display Bore automatics fully galvanised rod box semi-automatic rod exchange system semi-automatic clamp and break-away facility Anchoring system with drilling fluid collecting tray powerful HP Bentonite pump on board the rig Bore data log –telemetry data transfer optional:fully automatic system, percussive hammer, high pressure cleaner, wireless remote control, rubberisedsteel track undercarriage, air conditioning

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Cummins motor T4i for driving and drilling, 119 kW Drill rig with rubber track undercarriage, stabilisers Spacious cabin, comfortable seat, joysticks, LCD display Fully galvanised rod box Semi-automatic rod exchange system Semi-automatic clamp and break-away facility Anchoring system with drilling fluid collecting tray Powerful HP Bentonite pump on board the rig Bore data log Telemetry data transfer Optional: Bore automatics, percussive hammer, high pressure cleaner, wireless remote control, rubberised steel track undercarriage

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

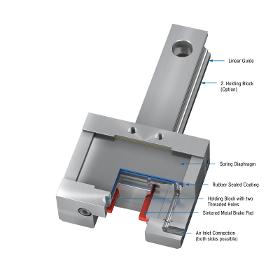

Pneumatic Rod Clamping, Compact Holding force 700 N Holding torque 7 Nm Compact and safe: when space becomes restricted, the compact LOCKED PRK clamping elements come into their own. As pneumatic rod clamping with low heights of 28 to 34 mm, they provide clamping forces of up to 5,000 N. Clamping is carried out by a diaphragm spring-plate system and is released when compressed air is applied. Clamping elements from the LOCKED PRK product family absorb the forces on rods with diameters between 20 and 40 mm both axially and rotationally. The function makes them suitable for use as static clamping without pressure, because the failure or drop of pneumatic pressure triggers immediate clamping. High clamping forces with low system costs compared with hydraulic and electric solutions make these clamping elements particularly interesting.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACE STOSSDÄMPFER GMBH

Germany

Process Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family PLK clamping elements are more compact than the Series PL components. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and space-saving. Thanks to the patented spring steel plate system, the LOCKED-Family PLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. LOCKED PLK achieve 100 % clamping force due to the steel pads that are used, even on greased rails. The clamping elements represent the maximum holding forces. Whether in the 4 or 6 bar version, they are good for up to 1 million cycles.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connectors – the flexible alternative to welded connections The clampable tube connectors from RK Rose+Krieger are a cost-efficient solution for the positive and ready detachable connection of a diverse variety of systems – without the need for drilling and welding. Depending on the field of application and the expected load, RK Rose+Krieger offers tube connectors made of plastic (Light Clamps), aluminium (Solid Clamps) or stainless steel (Robust Clamps). The Solid Clamps tube connector system also includes the RK monitor mounting for the fixation and ergonomic adjustment of monitors and touch screens used in industrial applications. Say goodbye to welding – that could be the motto of the clampable RK tube connectors The simple assembly technology of the clamping elements eliminates the need for time-consuming and cost-intensive drilling and welding work.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Custom-designed clamping systems for pipes, tubes, hoses, cables and other components according to customer`s specifications or based on STAUFF developments, made of thermoplastics, metals and non-ferrous metals. Accessories such as weld plates, cover plates, bolts as well as rubber inserts are available on request.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Custom-designed clamping systems for pipes, tubes, hoses, cables and other components according to customer`s specifications or based on STAUFF developments, made of Polypropylene, Polyamide and other thermoplastics. Accessories such as weld plates, cover plates, bolts as well as rubber inserts are available on request.

Request for a quote

TAS SCHÄFER GMBH

Germany

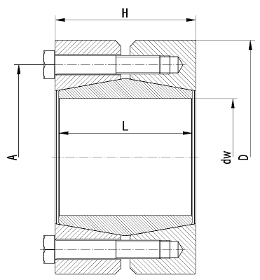

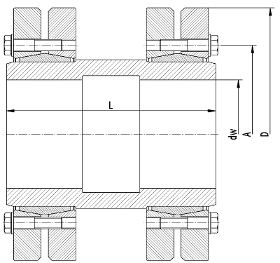

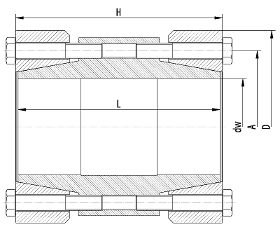

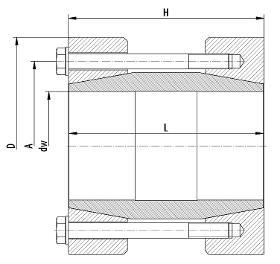

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

ABS SAFETY GMBH

Germany

Use this connector cable clamp to connect your lifeline system (6 or 8 mm) to a lightning conductor. This allows you to actively incorporate your anchorage device into your lightning conductor system - providing more effective protection against a lightning strike. Designed for 6 mm and 8 mm lifeline systems Connects your lifeline system to your lightning conductor

Request for a quote

ABS SAFETY GMBH

Germany

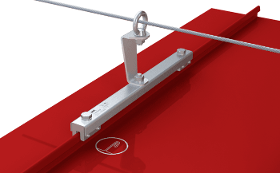

This stainless steel intermediate bracket - specially designed for lifeline systems - was developed for penetration-free installation on a standing seam roof. This device is attached using aluminium or brass clamps depending on your subsurface (steel, copper, aluminium or titanium zinc). EN 795:2012, C + CEN/TS 16415:2017 Clamped onto a standing seam without penetrating your roof surface Mounted on a single seam For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Designed exclusively for use in a lifeline system Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

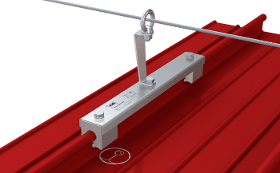

This stainless steel intermediate bracket allows you to install an ABS-Lock SYS lifeline system on a rounded-edge seam roof without penetrating your roof surface. The anchorage eyelet bracket is simply attached to a rounded-edge seam using the special clamps supplied. EN 795:2012, C + CEN/TS 16415:2013 Simply clamped onto a rounded-edge seam without penetrating your roof surface Mounted on a single seam For BEMO and similar systems Incl. installation set Designed exclusively for use in a lifeline system

Request for a quoteResults for

Clamping systems - Import exportNumber of results

39 ProductsCategory

- Electroheat - machines and equipment (2)

- Transport, indoor - rolling equipment (2)

- Sawing machine tools (1)

- Components and parts for small household appliances (1)

- Elements, electric (1)

- Fittings, pipe, tube and hose - plastic (1)

- Forming - steels and metals (1)

- Grinding - steels and metals (1)

- Metal industrial presses (1)

- Metal straightening machines (1)

- Pipes and tubes - ferrous metal (1)

- Pipes and tubes, aluminium (1)