- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping parts

Results for

Clamping parts - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Compact and light-weight design for applications in which space is limited ▪ Available in 3 different sizes and covering all standard metric and imperial diameters between 4 mm and 32 mm / .16 inch and 1.26 inch ▪ Vibration/noise-reducing clamp body material with UV, ozone and weathering-resistant characteristics ▪ Advanced design with a film hinge allows the top part of the clamp body to open up and insert or replace the pipe, tube or hose without the use of force ▪ Embedded metal sleeve to ensure stability of the clamp assembly Please also ask for the Anti-Twist Feature to prevent turning of the components.

Request for a quote

TAS SCHÄFER GMBH

Germany

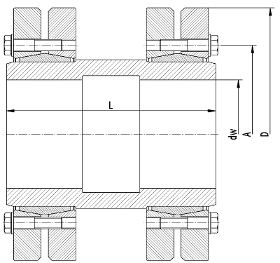

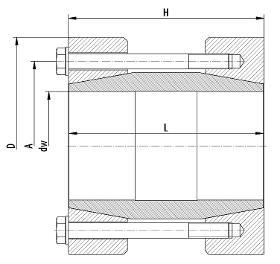

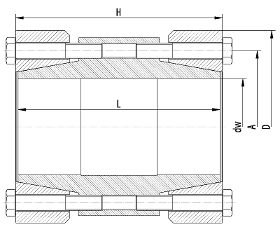

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROHRE-KETTERER GMBH

Germany

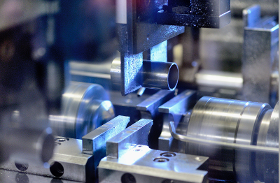

Stamping of especially thin-walled tubes with high demands on precision and a burr-free surface is one of our specialities. We are stamping with full and half automated stamping units and can produce any stamping geometry in one clamping withoud deforming the parts.

Request for a quote

ROHRE-KETTERER GMBH

Germany

Stamping of especially thin-walled tubes with high demands on precision and a burr-free surface is one of our specialities. We are stamping with full and half automated stamping units and can produce any stamping geometry in one clamping withoud deforming the parts.

Request for a quoteResults for

Clamping parts - Import exportNumber of results

8 ProductsCompany type